What is the Importance of Best Dot Peen Marking Machines in Modern Manufacturing Environments

In the fast-paced realm of modern manufacturing, precision and efficiency are paramount, making the role of advanced technologies increasingly crucial. Among these innovations, the Dot Peen Marking Machine stands out as a vital tool for marking and engraving materials with unparalleled accuracy and speed. This technology utilizes a series of controlled dots to create alphanumeric characters and designs on various surfaces, ensuring that every mark is clear, permanent, and tamper-proof. As industries strive to enhance product traceability and compliance with strict regulations, the importance of implementing high-quality dot peen marking machines cannot be overstated. This guide will delve into the significance of these machines in contemporary manufacturing environments, exploring their benefits, diverse applications, and the factors to consider when selecting the best equipment for your business needs.

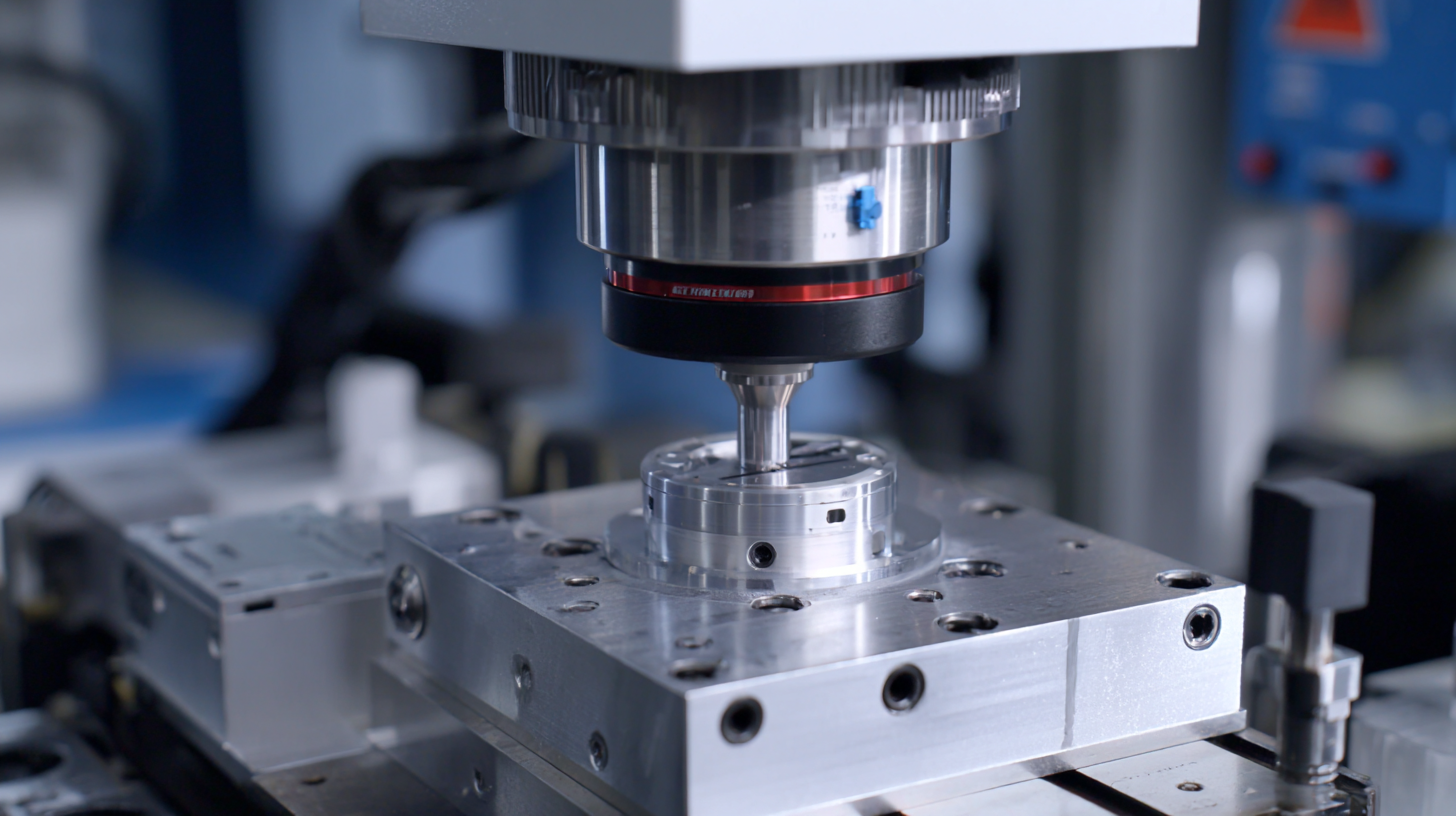

Understanding Dot Peen Marking Technology and Its Role in Manufacturing Efficiency

Dot peen marking technology plays a pivotal role in enhancing manufacturing efficiency by providing high-quality, precise marking solutions that streamline production processes. According to a report by MarketsandMarkets, the global industrial marking system market is projected to reach $5.3 billion by 2025, growing at a CAGR of 4.5%. This underscores the increasing demand for efficient marking technologies in modern manufacturing environments. Dot peen marking machines are particularly valued for their ability to produce durable and legible markings on a wide array of materials, ensuring compliance with quality and traceability standards.

The efficiency brought by dot peen marking also extends to reduced downtime and lower operational costs. A study from the International Journal of Advanced Manufacturing Technology found that implementing automatic marking systems can decrease manufacturing cycle times by up to 30%. Additionally, the integration of these machines with automated systems allows for real-time production data tracking, further optimizing workflow and resource allocation. As manufacturers continue to prioritize efficiency and precision, dot peen marking technology stands out as a crucial component in the advancement of modern production methodologies.

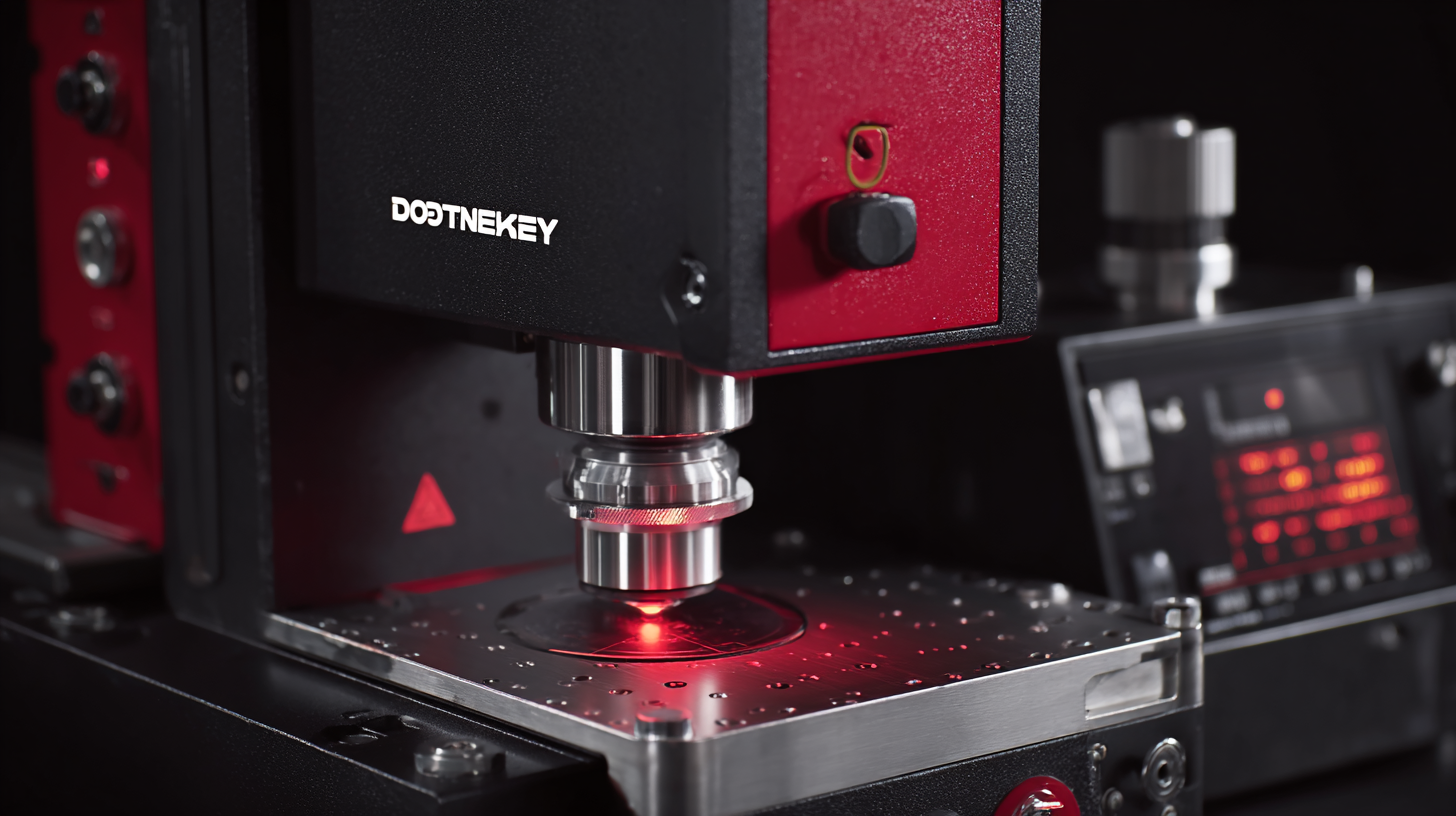

Key Features of Dot Peen Marking Machines and Their Impact on Product Identification

Dot peen marking machines play a crucial role in modern manufacturing environments by providing durable and high-quality identification on various materials. One of the key features of these machines is their ability to create permanent marks that are resistant to wear and environmental conditions. This reliability makes them indispensable for product traceability and compliance with industry regulations. Manufacturers can enhance their efficiency by utilizing dot peen marking technology, which not only ensures a clear identification system but also minimizes errors during production.

Tips for effective use of dot peen marking machines include ensuring regular maintenance to prolong machine longevity and optimize performance. Additionally, selecting the right marking parameters—such as impact depth and speed—can significantly enhance the visibility and clarity of the markings. Training operators on machine handling can further improve the consistency of markings, which is essential for maintaining high-quality standards in product identification.

Moreover, businesses should consider integrating advanced software solutions with dot peen marking machines. This allows for better data management and the ability to easily update marking information as needed. By combining these features, manufacturers can streamline their marking process, leading to increased productivity and reduced downtime.

Industry Standards and Regulations Shaping the Use of Dot Peen Marking in Manufacturing

In modern manufacturing environments, compliance with industry standards and regulations is becoming increasingly critical, particularly concerning marking and identification methods. The demand for robust and traceable marks has driven the growth of the industrial marking equipment market, projected to expand steadily from 2025 to 2035. This evolution is largely influenced by the necessity for precision and security in direct part marking, especially as manufacturers seek to meet stringent regulations regarding product traceability and identification.

The dot peen marking machine sector is experiencing significant growth, with the market size estimated at USD 514.8 million in 2024 and expected to rise in the coming years. This growth reflects an increasing reliance on technologies that facilitate direct part marking, which provides indelible markings suited for machine vision codes. Such developments underline the importance of dot peen marking in fulfilling regulatory requirements and enhancing production efficiency, ensuring that manufacturers can demonstrate compliance with safety and traceability standards while maintaining high-quality outputs.

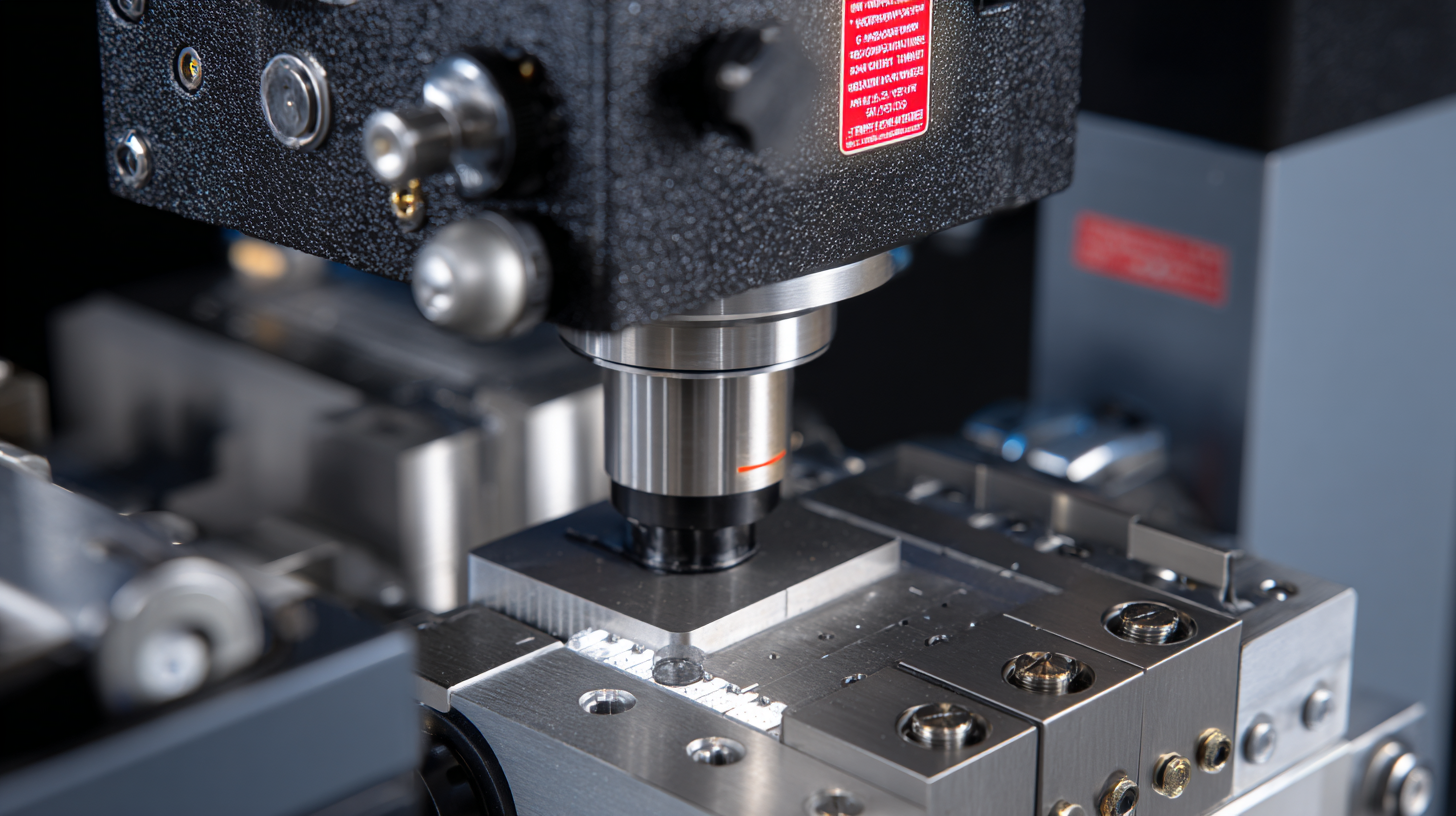

Comparative Analysis: Dot Peen Marking vs Other Marking Technologies in Production

In the realm of modern manufacturing, the choice of marking technology plays a crucial role in product identification and traceability. Dot peen marking machines stand out due to their precision and efficiency, especially when compared to other marking alternatives such as laser engraving and inkjet printing. The dot peen process creates durable marks by impacting the surface of the material, which not only ensures high readability but also withstands harsh environmental conditions. This makes it particularly suitable for industries where robustness is essential, such as automotive and aerospace.

When evaluating dot peen marking against laser and inkjet technologies, one must consider factors such as speed, material versatility, and cost-efficiency. Laser marking offers non-contact precision and is excellent for intricate designs but may require additional safety protocols due to its high-energy equipment. In contrast, inkjet marking provides flexibility for variable data but often lacks the permanence needed in demanding production settings. Dot peen marking emerges as a balanced solution, delivering reliable performance across diverse materials while minimizing the risk of wear or fading, thus enhancing overall productivity in manufacturing processes.

Real-World Applications of Dot Peen Marking Machines Across Various Industries

Dot peen marking machines have become essential tools across various industries due to their precision and durability. These machines create permanent markings on materials, which is crucial for product identification, traceability, and compliance with industry standards. According to a report by MarketsandMarkets, the industrial marking equipment market is projected to reach $5.3 billion by 2026, with a significant portion attributed to dot peen technology. This increase is driven by the rising need for efficient inventory management systems and enhanced safety measures in manufacturing processes.

In the automotive sector, dot peen marking machines are particularly valuable. They ensure that components are marked with vital information such as serial numbers and barcodes, facilitating easier tracking throughout the supply chain. A study conducted by Automotive News found that 76% of manufacturers consider marking and coding systems essential for maintaining quality control and compliance with regulations. Similarly, in the aerospace industry, where traceability is paramount, dot peen marking is employed extensively for marking intricate parts, which helps in avoiding costly recalls and enhances safety protocols. The integration of these machines is not just a trend; it is becoming a standard practice in manufacturing for ensuring operational efficiency and compliance.

What is the Importance of Best Dot Peen Marking Machines in Modern Manufacturing Environments - Real-World Applications of Dot Peen Marking Machines Across Various Industries

| Industry | Application | Benefits of Dot Peen Marking | Materials Typically Marked |

|---|---|---|---|

| Automotive | Part identification and traceability | Durable markings, high-speed processing | Metal components, plastics |

| Aerospace | Component marking for compliance | Precision, withstands harsh environments | Aluminum, titanium |

| Electronics | Circuit board marking | High resolution, non-destructive | Glass, silicone |

| Construction | Large equipment marking | Enhanced traceability, weather-resistant | Steel, copper |

| Medical | Device and instrument identification | Compliance with regulations, sterile resistant | Stainless steel, plastics |