5 Key Industries Revolutionizing Production with the Best Dot Peen Marking Machine

In today's rapidly evolving manufacturing landscape, the implementation of advanced technologies has become imperative for achieving operational efficiency and product quality. Among these innovations, the Dot Peen Marking Machine has emerged as a pivotal tool for various industries, ensuring that identification and traceability needs are met with precision. According to a recent market report by Research and Markets, the global marking machine market is projected to reach $4.5 billion by 2026, with the dot peen segment witnessing significant growth due to its reliability and versatility. These machines are not only capable of creating permanent marks on a range of materials but also play a crucial role in enhancing production processes in key sectors such as automotive, aerospace, electronics, and metal fabrication. As leading Chinese manufacturers continue to refine these technologies, the trust in their products grows globally, solidifying the position of Dot Peen Marking Machines as essential assets for revolutionizing production methodologies.

Key Features of Dot Peen Marking Machines and Their Applications

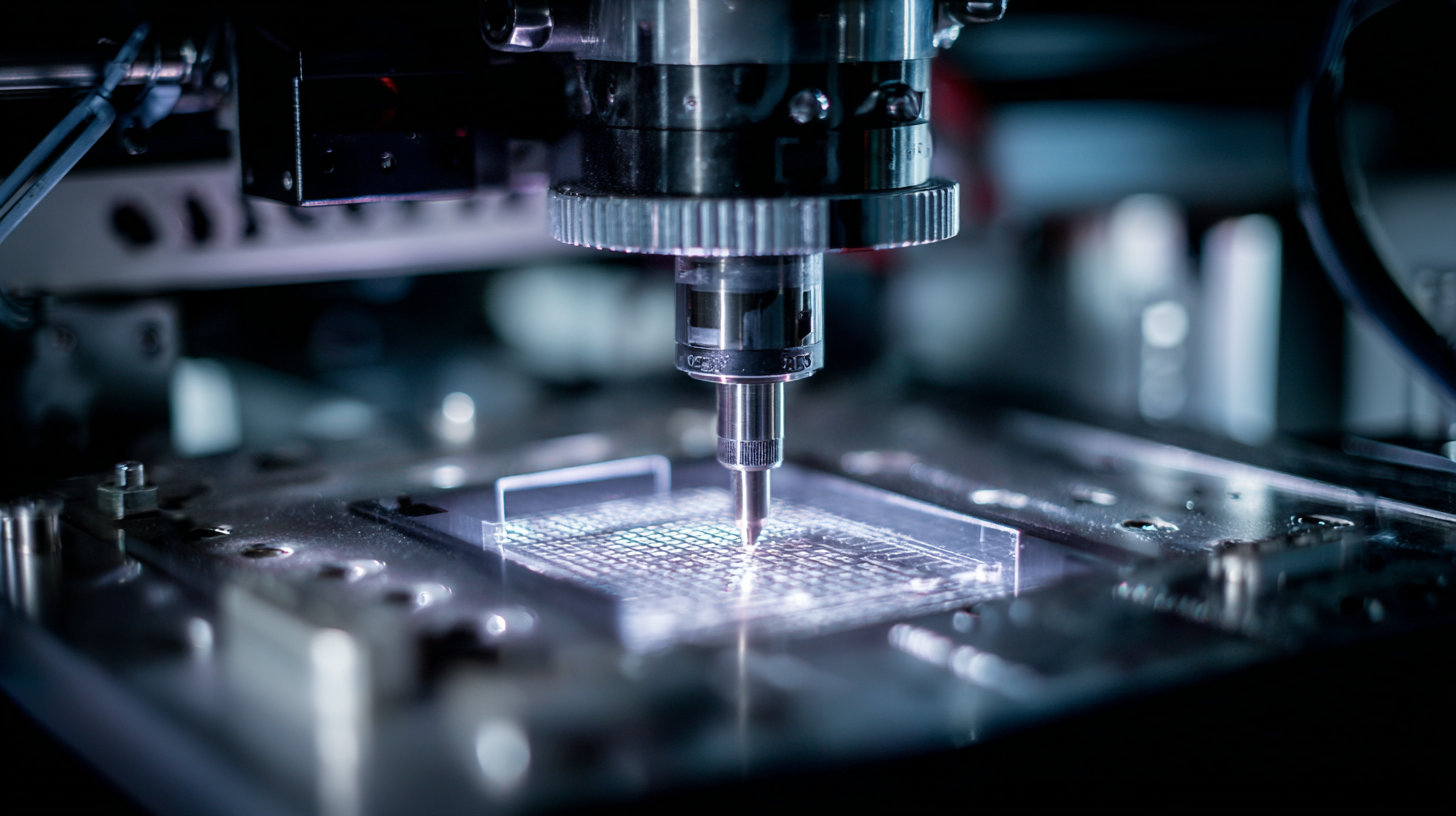

Dot peen marking machines are transforming production across various industries by providing precise, permanent markings on a wide range of materials. These machines utilize a stylus that impacts the surface to create text and logos, making them essential in sectors such as automotive, aerospace, and manufacturing. According to a report from MarketsandMarkets, the global market for marking machines is projected to reach USD 4.28 billion by 2025, driven by the need for high traceability in production processes.

Key features of dot peen marking machines include their ability to work on various materials like metals, plastics, and ceramics, as well as their durability and speed. For instance, these machines can mark at speeds of up to 200 characters per second, significantly enhancing production efficiency. Moreover, they support various marking formats and sizes, catering to the specific needs of different industries.

The versatility of dot peen technology allows companies to meet stringent industry regulations on product identification, which is crucial in sectors where compliance is paramount, such as pharmaceuticals and electronics, where a study from Frost & Sullivan indicates that stringent traceability standards could drive a 15% growth in this segment by 2025.

Exploring the Role of Dot Peen Marking in Various Industries

The utilization of dot peen marking technology is transforming several key industries by enhancing traceability, quality assurance, and productivity. In the automotive sector, for instance, the integration of marked part identification has surged in demand, with a study by MarketsandMarkets indicating that the automotive marking and coding market is expected to reach $3.1 billion by 2025, growing at a CAGR of 5.5%. The precision and durability offered by dot peen marking make it ideal for permanent part identification, helping manufacturers comply with stringent regulatory standards.

In the aerospace industry, the adoption of dot peen marking is critical for maintaining the integrity and safety of components. Industry reports highlight that significant investments are being made in additive manufacturing and marking technologies to streamline production processes. According to a report by Research and Markets, the aerospace marking systems market is anticipated to grow significantly, driven by an increased focus on quality and the need for real-time traceability. Dot peen marking enables aerospace manufacturers to ensure that every part is traceable and meets the necessary safety specifications, thereby minimizing potential risks.

The electronics sector also benefits from dot peen marking, where the technology supports the unique identification of components to enhance inventory management and reduce errors during assembly. A survey by Technavio suggests that the global electronics marking and labeling market will grow by $3.5 billion from 2021 to 2025. This growth reflects the rising importance of automation and precision in production, reinforcing dot peen marking's critical role in modern manufacturing processes across various industries.

Comparative Analysis: Dot Peen vs. Other Marking Technologies

In the evolving landscape of industrial production, the choice of marking technology can significantly influence efficiency and precision. Dot peen marking, renowned for its durability and versatility, stands out against other marking methods like laser and inkjet technology. Unlike laser marking, which can be limited by material type and thickness, dot peen marking is effective on a wide range of substrates, including metals and plastics. This adaptability makes it a preferred option for many industries, such as automotive and aerospace, where robust and permanent identification is crucial.

Moreover, when compared to inkjet marking, dot peen systems avoid issues related to ink smudging and the necessity for frequent cartridge changes. This not only reduces downtime but also cuts costs in the long run. Furthermore, dot peen machines are often easier to integrate into production lines, allowing for seamless operations without extensive modifications. As businesses continue to prioritize efficiency and resilience in their marking solutions, dot peen technology emerges as a compelling choice for those seeking both reliability and superior performance.

Innovative Use Cases: How Industries Benefit from Dot Peen Solutions

Dot peen marking machines are transforming production processes across various industries by providing high-quality, durable markings that enhance traceability and quality control. In the automotive sector, for example, manufacturers use these machines to mark critical components with serial numbers and barcodes, ensuring compliance with safety regulations and facilitating easy tracking of parts throughout the supply chain. This not only streamlines inventory management but also enhances customer trust in the product.

Moreover, the aerospace industry benefits significantly from dot peen technology. Components are subjected to rigorous quality standards, and precise markings are essential for identification and maintenance purposes. With dot peen marking, manufacturers can apply permanent, readable marks without compromising the integrity of the materials. This aids in reducing downtime during inspections and enhances operational efficiency. Additionally, industries like electronics and medical devices are adopting dot peen solutions to ensure detailed traceability, where the accuracy and permanence of markings are critical for compliance and safety regulations.

Future Trends in Production Marking: Advancements and Opportunities

The landscape of production marking is evolving rapidly, driven by advancements in technology and the emergence of new opportunities in various industries. As companies increasingly adopt non-metal laser engraving machines, the market is projected to grow from $359.1 million in 2024 to $575.9 million by 2032, reflecting a steady growth rate of 6.1%. This upward trend highlights the importance of precision and efficiency in production processes, where marking plays a critical role in enhancing product traceability and brand identity.

Future trends indicate that the integration of data and analytics will continue to be a cornerstone for success. Organizations are utilizing advanced analytical tools to segment consumer groups more effectively, allowing for tailored products and services. This level of customization not only amplifies consumer satisfaction but also drives competitive advantage in the marketplace. As the demand for innovative production techniques rises, industries must embrace these technological advancements to stay ahead in an increasingly sophisticated economic environment.

5 Key Industries Revolutionizing Production with the Best Dot Peen Marking Machine

| Industry | Market Size (2023) | Growth Rate (%) | Dot Peen Marking Application | Future Trends |

|---|---|---|---|---|

| Automotive | $250 Billion | 4.5% | Part Identification | Increased automation |

| Aerospace | $120 Billion | 5.0% | Traceability | Integration of smart technologies |

| Electronics | $180 Billion | 6.5% | Component Marking | Focus on miniaturization |

| Medical Devices | $90 Billion | 7.0% | Serial Numbering | Regulatory compliance |

| Construction | $300 Billion | 3.8% | Material Identification | Sustainability focus |