Exploring Innovative Applications of the Best Laser Marking Machine in Global Markets

The Laser Marking Machine industry has been experiencing remarkable growth, driven by its versatile applications across various sectors such as electronics, automotive, and medical devices. According to a recent research report by MarketsandMarkets, the global laser marking market is projected to reach USD 4.05 billion by 2025, growing at a CAGR of 6.5% from 2020 to 2025. The increasing demand for permanent identification, traceability of products, and customization options has further propelled the adoption of laser marking technology in manufacturing processes.

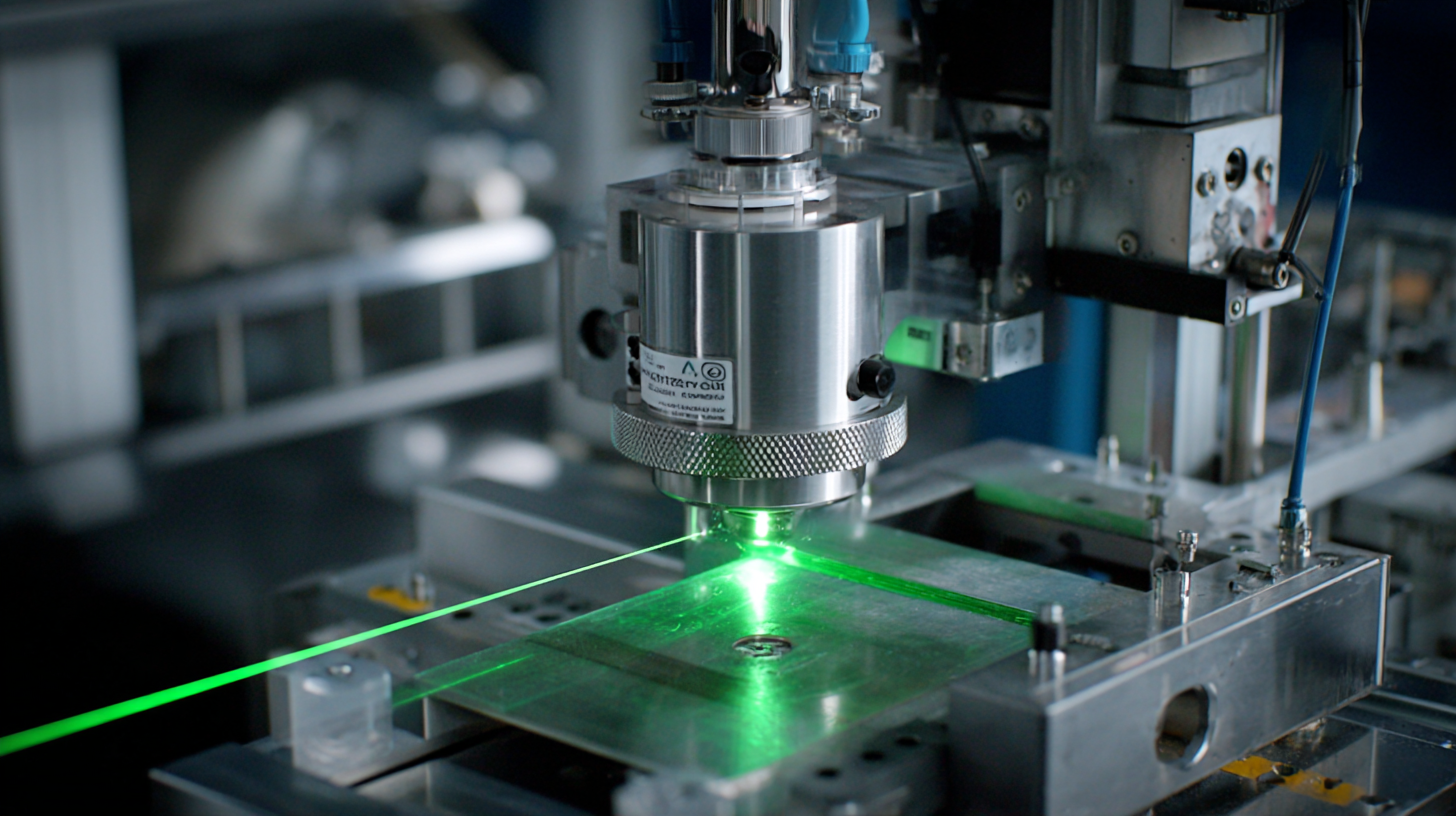

This blog delves into the innovative applications of Laser Marking Machines, highlighting not only their technical specifications but also insightful tutorials aimed at maximizing their effectiveness in diverse global markets. As industries continue to evolve, understanding the operational capabilities and advantages of these machines becomes critical for stakeholders aiming to leverage cutting-edge solutions.

Innovative Technologies Shaping the Future of Laser Marking Machines

The landscape of laser marking technology is rapidly evolving, driven by innovation and increasing market demands. According to a recent market research report by Mordor Intelligence, the global laser marking machine market is expected to grow at a CAGR of over 6% between 2021 and 2026. This growth is fueled by advancements in laser technologies, such as fiber lasers, which offer higher efficiency and precision, making them ideal for diverse applications ranging from electronics to medical devices.

Innovative technologies are shaping the future of laser marking machines, enhancing their capabilities and expanding their applications. The integration of AI and machine learning algorithms in laser marking systems is optimizing marking processes, reducing operational downtime, and improving product traceability. Furthermore, the advent of portable laser marking machines allows businesses to perform on-site marking, boosting productivity and lowering transportation costs.

Tip: When selecting a laser marking machine, consider the type of material you will be working with and the specific marking requirements. This ensures optimal performance and longevity of the equipment. Additionally, staying informed about the latest technological advancements can help businesses leverage innovations for competitive advantages.

Market Share of Innovative Laser Marking Applications (2023)

This chart illustrates the distribution of market share among various innovative applications of laser marking machines in global markets for the year 2023. The applications include automotive, electronics, packaging, and medical devices.

Key Alternatives to Traditional Laser Marking Solutions in Various Industries

In recent years, various industries have begun to explore key alternatives to traditional laser marking solutions, driven by the need for more efficient and customizable marking processes. According to a report by MarketsandMarkets, the global laser marking machine market is projected to reach USD 4.2 billion by 2026, growing at a CAGR of 5.7%. This growth is fueled by the increasing demand for high-precision marking technology in industries such as automotive, electronics, and pharmaceuticals.

One significant alternative gaining traction is fiber laser marking, which offers greater speed and efficiency compared to traditional CO2 lasers. Fiber lasers are particularly effective for marking on metals and plastics, making them ideal for the automotive and electronics sectors, where durability and precision are paramount. In fact, a study from ResearchAndMarkets indicates that fiber laser technology is expected to dominate the market, holding over 40% share by 2025 due to its adaptability and lower operational costs.

Additionally, advancements in integrated laser marking systems are transforming manufacturing processes, enabling real-time data tracking and enhanced product identification. The use of these innovative systems not only reduces waste but also improves compliance in heavily regulated industries, such as medical devices and aerospace. As companies continue to seek efficient solutions to meet their marking needs, these alternatives demonstrate the evolution of laser marking technology in adapting to global market demands.

Comparative Analysis of Laser Marking Machines vs. Other Marking Technologies

The laser marking technology is gaining substantial traction in various industries due to its precision and efficiency compared to traditional marking technologies. A comparative analysis reveals that while methods like inkjet and mechanical engraving have their merits, laser marking machines offer cleaner, more durable, and versatile solutions. Specifically, laser systems, such as fiber and CO2 lasers, can produce high-quality markings on a broader range of materials, allowing manufacturers to enhance their product traceability and branding.

When considering the investment in laser marking machines, businesses should focus on specific requirements and material compatibility. It is essential to assess how different laser types, including solid-state and UV lasers, can align with production goals and operational efficiencies.

**Tips:** It’s advisable to conduct a cost-benefit analysis when choosing between laser marking and other technologies. Additionally, investing in training for operators can significantly improve the efficacy of the laser marking process and ensure the longevity of the equipment. Regular maintenance checks will also optimize performance and reduce downtime, ultimately supporting sustained business growth in an increasingly competitive market.

Exploring Innovative Applications of the Best Laser Marking Machine in Global Markets - Comparative Analysis of Laser Marking Machines vs. Other Marking Technologies

| Technology Type | Precision (µm) | Speed (markings/minute) | Material Compatibility | Initial Investment ($) | Maintenance Cost ($/year) |

|---|---|---|---|---|---|

| Laser Marking | 20 | 600 | Metals, Plastics, Glass | 50,000 | 1,000 |

| Inkjet Printing | 100 | 300 | Paper, Plastics | 20,000 | 400 |

| Dot Peen Marking | 50 | 200 | Metals, Hard Plastics | 30,000 | 600 |

| Laser Engraving | 15 | 400 | Wood, Leather, Glass | 40,000 | 800 |

Emerging Trends in Laser Marking Applications Across Global Markets

The evolving landscape of laser marking technology is witnessing a surge in innovative applications across diverse global markets. One of the most significant trends is the increased adoption of laser marking in the automotive and aerospace sectors, where precision and durability are paramount. These industries require advanced traceability solutions, and laser marking offers a reliable method for engraving critical information onto parts and components. As manufacturers seek to enhance product compliance and safety, the demand for high-quality laser marking solutions continues to grow.

Additionally, the rapid development of compact and efficient laser micromachining tools is reshaping various sectors, from electronics to medical devices. With applications ranging from intricate engraving to high-speed cutting, these tools are revolutionizing production processes. One notable influence is the rise of personalized products, where consumers expect bespoke branding and customization, further propelling the need for versatile laser marking systems. As these emerging trends unfold, businesses are encouraged to explore the full potential of laser marking technology to enhance their operational efficiencies and meet evolving market demands.

Case Studies of Successful Laser Marking Implementations in Diverse Sectors

Laser marking technology has witnessed a remarkable transformation across various industries, showcasing its versatility and efficiency in real-world applications. One striking case study is in the medical device sector, where precision and hygiene are paramount. A leading manufacturer implemented a state-of-the-art laser marking machine to etch serial numbers and barcodes onto surgical instruments. This not only enhanced traceability but also streamlined inventory management and compliance with regulatory standards. The laser's ability to create permanent and tamper-proof markings ensured that the devices met stringent safety requirements, thereby minimizing risks associated with product recalls.

In the automotive industry, a prominent car manufacturer adopted laser marking technology to improve its branding and traceability efforts. By using high-speed laser marking machines, the company was able to mark VINs (Vehicle Identification Numbers) directly onto metal parts with high accuracy. This resulted in significant time savings during assembly processes, as well as improved durability of the markings. Additionally, the machine's capability to deliver intricate designs allowed the manufacturer to introduce custom branding options, appealing to a growing market of personalized vehicles. Such implementations illustrate how laser marking is transforming operational efficiencies and elevating brand identities across global markets.