2025 Top Blister Pack Sealing Machine: Innovations & Best Practices

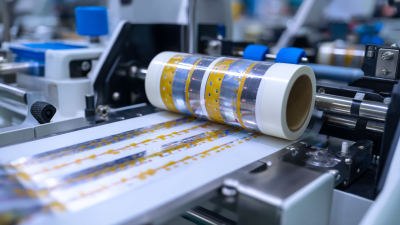

In the fast-evolving landscape of packaging technology, the blister pack sealing machine stands out as a critical innovation, especially in the pharmaceutical and consumer goods sectors. According to Dr. Emily Carter, a leading expert in packaging technologies, "The efficiency and versatility of blister pack sealing machines are redefining how we approach packaging solutions in a sustainable and market-driven world." As we look toward 2025, it becomes essential to explore the latest innovations and best practices surrounding these machines.

The blister pack sealing machine not only ensures product integrity but also enhances user experience by providing tamper-proof and visually appealing packaging. With advancements in automation, material sciences, and digital technologies, manufacturers are now equipped to produce more efficient, cost-effective, and eco-friendly packaging solutions. This article delves into the key developments expected by 2025, focusing on technological innovations and operational best practices that will shape the future of the blister pack sealing industry.

Understanding these dynamics is crucial for businesses aiming to optimize their packaging processes. By leveraging new technologies and insights from industry leaders like Dr. Carter, stakeholders can make informed decisions that align with market demands and sustainability goals, ultimately paving the way for a more efficient packaging landscape.

Advancements in Blister Pack Sealing Technology for 2025

The blister pack sealing technology has seen remarkable advancements leading up to 2025, driven by the need for enhanced efficiency and sustainability in the packaging sector. Modern machines now incorporate sophisticated automation and AI algorithms, enabling them to operate with precision and speed. These innovations not only reduce production costs but also minimize waste, allowing manufacturers to streamline their processes while adhering to environmental regulations. The ability to customize sealing parameters in real-time also ensures that different products can be efficiently packaged without extensive downtime.

Moreover, the integration of smart sensors and IoT connectivity in blister pack sealing machines has transformed quality control measures. By enabling real-time monitoring, manufacturers can rapidly detect any deviations in the sealing process, ensuring that products meet stringent safety and quality standards. This level of oversight not only enhances product integrity but also builds consumer trust in packaging. As companies prioritize sustainability, the trend towards eco-friendly materials and energy-efficient machines is likely to dominate the blister pack sealing industry in 2025 and beyond, paving the way for a greener future in packaging solutions.

2025 Top Blister Pack Sealing Machine: Innovations & Best Practices

| Feature | Description | Advancements | Best Practices |

|---|---|---|---|

| Temperature Control | Enhanced systems for precise temperature regulation. | Use of advanced thermoregulation sensors. | Regular calibration and maintenance of temperature sensors. |

| Material Compatibility | Wide range of materials suited for sealing. | Integration with multi-material capabilities. | Testing of all new materials prior to production. |

| Sealing Speed | Higher sealing speeds, enhancing productivity. | Advanced servo-driven motors for faster operations. | Optimize machine settings for maximum output. |

| Automation | Increased automation for reduced manual intervention. | Incorporation of robotics and AI systems. | Training staff on advanced systems to ensure smooth operation. |

| Quality Assurance | Stringent quality checks integrated into the process. | Real-time monitoring systems for defect detection. | Implement a rigorous testing protocol post-production. |

Key Features to Look for in a Blister Pack Sealing Machine

In selecting a blister pack sealing machine for 2025, certain key features can significantly enhance production efficiency and product integrity. One crucial aspect to consider is the machine's sealing technology. According to a report by the Freedonia Group, advancements in heat sealing methods can increase production speed by up to 30%, allowing manufacturers to meet growing demand without sacrificing quality. Machines equipped with automated temperature controls ensure consistent sealing results, reducing the likelihood of defects.

Another important feature is the machine's versatility in accommodating different blister formats and materials. As the packaging industry trends towards more sustainable options, machines that can handle recyclable or bio-based materials are becoming increasingly vital. A report from Smithers Pira indicates that the global market for sustainable packaging is projected to grow at a CAGR of 7.5% through 2025, emphasizing the need for flexibility in manufacturing processes. Additionally, user-friendly interfaces and advanced monitoring systems enable operators to adjust parameters in real-time, enhancing operational efficiency and product traceability.

Best Practices for Efficient Operation and Maintenance

Efficient operation and maintenance of blister pack sealing machines in 2025 will pivot on adopting best practices derived from recent industry innovations. As seen in various reports, businesses that leverage advanced technologies and robust management systems can enhance operational stability and performance. According to a recent "Core Capabilities and Best Practices" report on hybrid cloud operations, companies that implement structured operation frameworks experience a significant reduction in downtime and increased productivity, critical factors in industries reliant on timely packaging solutions.

Tips: Regularly updating your maintenance protocols can lead to improved machine longevity and reliability. Furthermore, utilizing AI-driven maintenance tools can proactively identify potential issues before they disrupt operations, giving your team the capacity to respond swiftly.

Additionally, as the necessity for data-driven decision-making grows, seamless integration of data analytics in maintenance and operational strategies will be vital. Reports indicate that organizations harnessing AI tools can automate routine tasks, enhancing both speed and accuracy. Incorporating such technologies into the operation of blister pack sealing machines not only ensures efficiency but also supports a culture of continuous improvement.

Top 5 Innovations Transforming the Blister Packaging Industry

The blister packaging industry is witnessing a transformative shift driven by innovative strategies aimed at enhancing efficiency and sustainability. Industry projections indicate that the global medicine blister market will grow from USD 22.9 billion in 2025 to USD 38.8 billion by 2035, underscoring a compound annual growth rate (CAGR) poised to reshape the sector significantly. Key innovations include the integration of smart technology, which ensures improved drug adherence and patient convenience, alongside eco-friendly packaging solutions that cater to the rising demand for sustainability.

Another notable trend in blister packaging is the emergence of advanced digital labeling techniques. These innovations not only enhance the informational value of packaging but also facilitate compliance with regulatory standards. The Sustainable Packaging Coalition highlights such advancements as crucial movements to watch in 2024, particularly with the focus on SPC.AI technology, which leverages artificial intelligence to optimize packaging design and material selection. As these trends evolve, they promise to redefine industry practices, emphasizing a balance between innovation and traditional methods that have long characterized pharmaceutical packaging.

Case Studies: Successful Implementation of Blister Pack Sealers

In the realm of pharmaceutical packaging, the implementation of advanced blister pack sealing machines has proven pivotal for enhancing product integrity and shelf life. A study by Grand View Research indicates that the global blister packaging market is expected to reach $32.5 billion by 2025, highlighting the growing importance of efficient sealing technologies. Companies adopting automated blister pack sealers have reported significant reductions in production costs and improved operational efficiency, aligning with the surge in demand for high-quality packaging solutions.

One notable case study involves a leading pharmaceutical company that integrated a state-of-the-art blister pack sealing machine into its production line. This innovation not only streamlined their packaging process but also increased their output by 30%. By leveraging real-time data analytics, the company optimized seal quality and adherence, minimizing defective products. The successful deployment of this technology not only met regulatory standards but also enhanced customer satisfaction through enhanced product reliability. As more industries recognize these benefits, investing in innovative blister pack sealing solutions will remain a critical focus for manufacturers looking to stay competitive.

Related Posts

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

-

Unlocking Efficiency: The Future of Blister Packaging Equipment in Modern Manufacturing