Exploring the Benefits of Investing in a High Quality Plastic Tray Sealing Machine

In the rapidly evolving packaging industry, the demand for efficient and high-quality solutions is paramount. Investing in a plastic tray sealing machine not only streamlines packaging processes but also enhances product shelf life and presentation. According to a recent report by Smithers Pira, the global market for food packaging is projected to grow at a CAGR of 3.5%, reaching $400 billion by 2025, largely driven by innovations in packaging technology. Plastic tray sealing machines play a crucial role in this transformation, offering benefits such as reduced food waste and improved hygiene standards. With an increasing emphasis on sustainability, these machines are designed to work with recyclable materials, aligning with consumer preferences and regulatory requirements. As companies seek to enhance operational efficiency and maintain competitive advantages, understanding the multifaceted benefits of investing in a high-quality plastic tray sealing machine becomes essential.

Benefits of Enhanced Packaging Integrity with Plastic Tray Sealing Machines

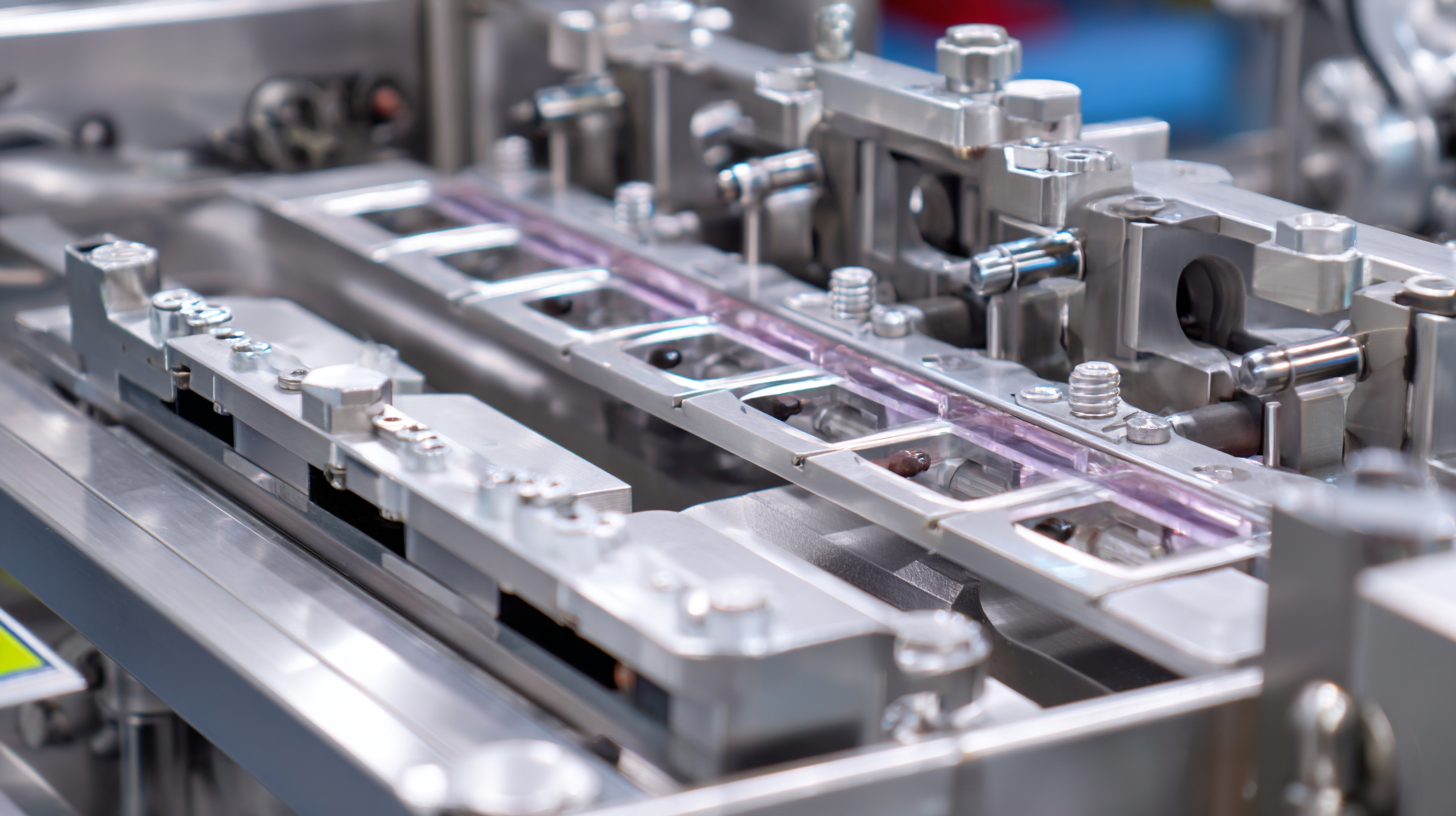

Investing in a high-quality plastic tray sealing machine significantly enhances packaging integrity, a vital aspect for businesses committed to delivering fresh and safe products. One of the main benefits of these machines is their ability to create airtight seals that protect food items from contaminants and extend shelf life. This is especially important in the food industry, where maintaining the quality and safety of perishable goods can directly impact customer satisfaction and brand reputation.

Moreover, plastic tray sealing machines provide consistent sealing performance, reducing the risk of human error often associated with manual sealing processes. With precise temperature and pressure controls, these machines ensure that each tray is sealed uniformly, preventing leaks and spoilage. The improved packaging integrity not only helps in maintaining product freshness but also enhances the visual appeal, as well-sealed trays often look more professional on retail shelves, further attracting consumers. In summary, the seamless functionality of high-quality tray sealing machines is essential for businesses looking to elevate their packaging standards while ensuring customer trust and satisfaction.

Exploring the Benefits of Investing in a High Quality Plastic Tray Sealing Machine - Benefits of Enhanced Packaging Integrity with Plastic Tray Sealing Machines

| Feature | Description | Benefit |

|---|---|---|

| Durability | Manufactured with high-quality materials that resist wear and tear. | Extends the lifespan of packaging, reducing the frequency of machine replacements. |

| Versatility | Compatible with various tray sizes and materials. | Allows adaptation to diverse product lines and packaging needs. |

| Seal Integrity | Creates airtight seals that prevent contamination. | Improves product shelf life and safety for end consumers. |

| Efficiency | High-speed operation reduces packaging time. | Increases production output and lowers labor costs. |

| User-Friendly Design | Easy-to-use controls and maintenance requirements. | Reduces training time for staff and minimizes downtime. |

Cost Savings from Reducing Product Waste and Spoilage

Investing in a high-quality plastic tray sealing machine can lead to significant cost savings for businesses by reducing product waste and spoilage. These machines ensure that food items are sealed tightly, extending shelf life and maintaining freshness. By minimizing exposure to air and contaminants, businesses can prevent spoilage, allowing for longer storage times and fewer losses. This not only boosts the bottom line but also improves inventory management, as companies can provide fresher products to their customers.

Investing in a high-quality plastic tray sealing machine can lead to significant cost savings for businesses by reducing product waste and spoilage. These machines ensure that food items are sealed tightly, extending shelf life and maintaining freshness. By minimizing exposure to air and contaminants, businesses can prevent spoilage, allowing for longer storage times and fewer losses. This not only boosts the bottom line but also improves inventory management, as companies can provide fresher products to their customers.

Tips for maximizing the efficiency of your tray sealing machine include:

- Conducting regular maintenance

- Investing in training for your staff

Another effective strategy is to monitor production closely. Tracking the rate of waste and spoilage will help identify areas for improvement and allow you to make informed decisions about ingredient sourcing and inventory levels. By refining these aspects, businesses can not only decrease waste but also enhance their overall profitability.

Improving Shelf Life and Product Freshness through Effective Sealing

Investing in a high-quality plastic tray sealing machine is essential for businesses looking to improve the shelf life and freshness of their products.

Effective sealing not only creates an airtight barrier that keeps moisture and contaminants at bay, but it also preserves the nutritional value and flavor of food items.

This technology plays a crucial role in the packaging process, helping to extend the longevity of perishable goods by minimizing exposure to air and bacteria.

Moreover, the precision provided by advanced sealing machines ensures consistent results across large production runs, which is vital for maintaining product quality.

Enhanced sealing techniques help reduce spoilage and waste, ultimately leading to higher customer satisfaction and trust.

By investing in top-notch sealing machinery, companies can optimize their packaging processes while delivering fresher, safer products to the market, making it a worthwhile investment in today's competitive landscape.

Customization Possibilities for Various Food Products and Sizes

Customization is becoming a pivotal factor in the food packaging industry, particularly for those investing in high-quality plastic tray sealing machines. These machines enable businesses to tailor their packaging to meet specific requirements for various food products and sizes, enhancing not only the visual appeal but also the functionality of the packaging. According to the latest market insights, the Global Kosher Beef market is anticipated to grow significantly, reflecting a broader trend among food producers to cater to niche markets with unique packaging solutions. This customization can play a critical role in attracting consumers who are increasingly looking for personalized food options, helping brands stand out in a competitive marketplace.

Moreover, as the demand for meal kit services rises, driven by the convenience of home-cooked meals, the importance of adaptable packaging cannot be overstated. Analysis from recent reports indicates that meal kit providers are focusing on sustainable and efficient packaging designs that can accommodate various meal sizes. Investing in advanced sealing technology allows these businesses to not only preserve the freshness of their products but also communicate their brand values through thoughtful packaging designs. As food delivery services evolve, the integration of such customizable packaging strategies will be essential for businesses aiming to meet consumer expectations and enhance their overall market presence.

Benefits of Investing in a High Quality Plastic Tray Sealing Machine

This chart illustrates the various benefits of investing in a high-quality plastic tray sealing machine for different food products and sizes. The data compares the efficiency improvement, cost reduction, and product variety offered by such machines.

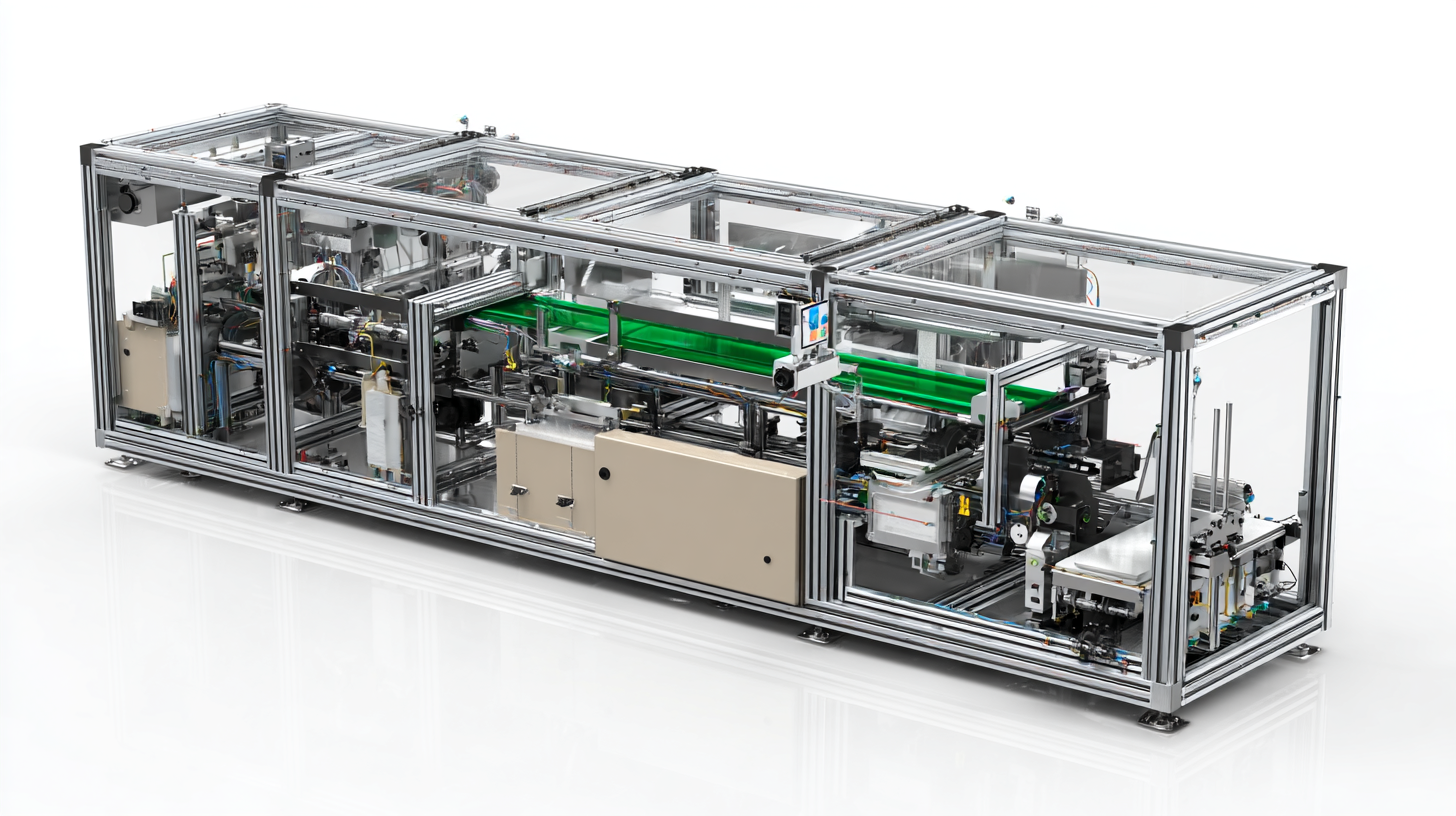

Streamlining Operations with Automated Sealing Solutions and Increased Efficiency

Investing in a high-quality plastic tray sealing machine can significantly transform production lines by streamlining operations through automation. Automated sealing solutions reduce the need for manual labor, allowing businesses to allocate resources more efficiently. With these machines, sealing processes become faster and more consistent, which minimizes the risk of errors commonly associated with human handling. This not only enhances productivity but also ensures that products maintain their freshness and integrity for longer periods.

Moreover, high-quality machines often come equipped with advanced technology that optimizes sealing parameters in real-time. This capability ensures a perfect seal every time, reducing waste and enhancing overall efficiency. Businesses can enjoy lower operational costs as higher productivity leads to increased outputs, allowing them to meet rising consumer demands quickly. The combination of automation and precision makes investing in a reliable plastic tray sealing machine a strategic move for companies aiming to enhance their operational performance and competitive edge.

Related Posts

-

How to Choose the Right Plastic Tray Sealing Machine for Your Business Needs

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency

-

Exploring the Future of Packaging Systems at China Import and Export Fair 2025: Insights and Innovations

-

How to Choose the Best Tray Packaging Machine for Your Business Needs

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

How to Optimize Your Production Line with a Tray Sealer Packaging Machine