Top 10 Benefits of Using Tray Sealer Packaging Machines for Your Business

In the fast-evolving landscape of food packaging, the adoption of advanced technologies is crucial for businesses seeking efficiency and sustainability. Among these innovations, the **tray sealer packaging machine** has emerged as a valuable asset, revolutionizing the way products are sealed and presented. According to a recent industry report, the global packaging machinery market is projected to reach $45 billion by 2026, with a notable segment driven by automated sealing solutions. This shift not only enhances operational productivity but also aligns with consumer demand for high-quality, well-preserved goods.

The rise in demand for convenience foods, coupled with stringent safety standards, has propelled the use of tray sealers in various sectors. Market analysis shows that packaging plays a critical role in influencing consumer purchasing decisions, with 67% of consumers stating that they would be willing to pay more for products that are packaged sustainably. By integrating a tray sealer packaging machine, businesses can significantly reduce spoilage rates and extend shelf life, leading to enhanced customer satisfaction and reduced waste. As companies continue to seek competitive advantages, understanding the benefits of these machines becomes essential for anyone invested in the food and beverage industry.

Benefits of Enhanced Product Freshness with Tray Sealers

Tray sealers offer significant advantages for businesses, particularly in terms of product freshness. By creating an airtight seal around food products, tray sealers effectively minimize exposure to air, moisture, and contaminants. This means that items like meats, vegetables, and ready-to-eat meals can maintain their flavor, texture, and nutritional value for longer periods. Enhanced freshness translates to reduced spoilage, allowing businesses to extend shelf life and minimize waste, ultimately leading to increased customer satisfaction and profitability.

When using tray sealers, consider incorporating best practices to maximize the benefits of enhanced freshness. First, ensure that your sealing machine is properly calibrated to create the tightest seal possible; an imperfect seal can compromise product quality. Additionally, choose packaging materials that are suited for your specific products, as different food items may require specialized films to maintain their freshness.

Another tip for businesses is to pay attention to the storage conditions post-packaging. Even with enhanced sealing, factors like temperature and humidity can affect product longevity. Storing these sealed products in optimal conditions will further enhance freshness and safety. By following these guidelines and investing in tray sealing technology, businesses can significantly improve the quality and appeal of their offerings.

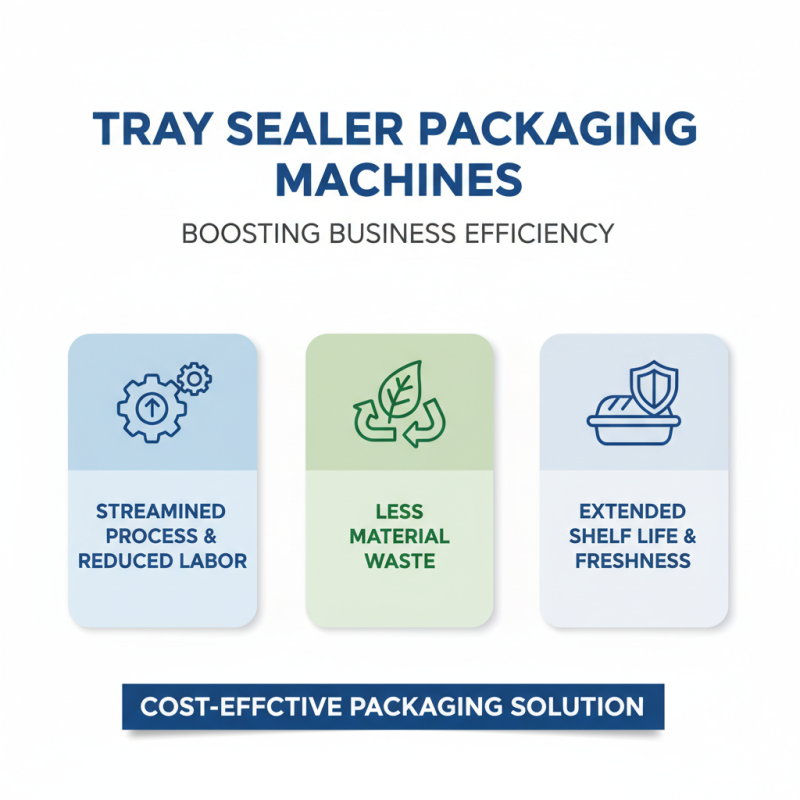

Cost Efficiency in Packaging Operations Using Tray Sealers

In today's competitive market, businesses are consistently seeking strategies to enhance cost efficiency in their packaging operations. One effective solution that has gained popularity is the implementation of tray sealer packaging machines. These machines not only streamline the packaging process but also significantly reduce material waste and labor costs. By utilizing tray sealers, companies can efficiently seal a wide variety of products, ensuring a longer shelf life while maintaining the quality and freshness of the items.

The versatility of tray sealers further contributes to cost efficiency. Organizations can customize packaging to suit diverse product sizes and shapes, accommodating different market demands without the need for extensive tooling or setup adjustments. This adaptability means reduced downtime and quicker turnaround times, allowing businesses to respond swiftly to changing consumer trends. Additionally, by automating the sealing process, companies can minimize the risk of human error, leading to fewer product recalls and waste, thereby bolstering overall profitability. As a result, investing in tray sealer packaging machines can provide a substantial return on investment and position businesses favorably in a cost-conscious landscape.

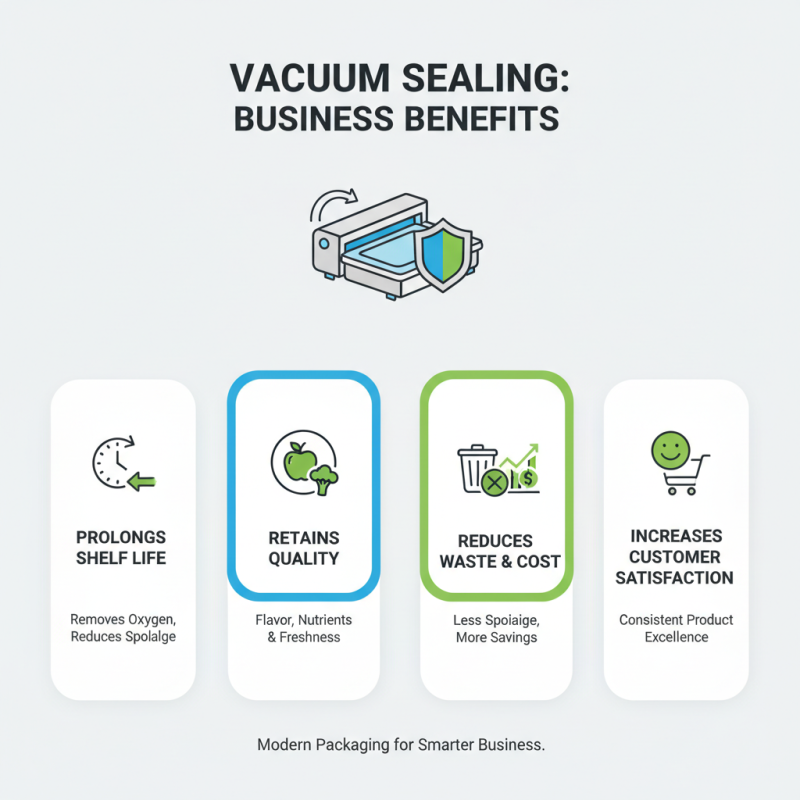

Improved Shelf Life Through Vacuum Sealing Techniques

Vacuum sealing has become an essential technique in modern packaging, particularly for businesses seeking to enhance the shelf life of their products. By creating an airtight seal, tray sealer packaging machines effectively remove oxygen, which is a key contributor to food spoilage. This innovative method not only prolongs freshness but also retains the flavor, nutrients, and overall quality of the items being packaged. As a result, businesses can reduce waste and increase customer satisfaction by ensuring that their products remain in optimal condition for longer periods.

For those interested in maximizing the benefits of vacuum sealing, consider these tips: First, always ensure that items are clean and dry before sealing, as moisture can lead to spoilage and compromise the seal. Second, pay attention to the compatibility of your packaging materials; using high-quality trays and films designed for vacuum sealing will enhance performance and durability. Lastly, train your staff on proper usage and maintenance of the tray sealing machines to achieve the best results and prevent any operational issues.

Incorporating vacuum sealing techniques into your packaging process not only elevates your products but also positions your business as one that prioritizes quality and customer care. By investing in the right equipment and following best practices, you can significantly improve your product's shelf life and overall market appeal, ultimately driving sales and establishing a loyal customer base.

Customizable Packaging Solutions for Varied Product Types

The ability to offer customizable packaging solutions is one of the most significant advantages of using tray sealer packaging machines. According to a report by MarketsandMarkets, the global packaging machinery market is expected to reach $53.3 billion by 2025, driven by the increasing demand for packaged foods and the need for flexible packaging options. Tray sealing technology allows businesses to tailor their packaging to meet the specific requirements of various products, whether it's fresh produce, meats, or prepared meals. This versatility not only enhances product appeal but also ensures that products maintain their quality and freshness.

Moreover, customizable tray sealing options enable businesses to respond quickly to changing market trends and consumer preferences. A study published by the Packaging Journal indicates that companies employing flexible packaging solutions have seen a 15% increase in customer retention rates and a 20% growth in new customer acquisition. This adaptability is crucial in today’s fast-paced market, allowing companies to experiment with different shapes, sizes, and materials without significant retooling costs. By meeting diverse consumer needs, businesses can maintain a competitive edge and achieve higher revenue growth while ensuring their products stand out on the shelves.

Top 10 Benefits of Using Tray Sealer Packaging Machines for Your Business

| Benefit | Description | Applicable Products | Cost Efficiency |

|---|---|---|---|

| Improved Shelf Life | Sealing trays helps in extending the shelf life of products by reducing spoilage. | Meat, Dairy, Prepared Foods | Medium |

| Customizable Sizes | Trays can be designed to fit specific product dimensions. | Vegetables, Fruits, Snacks | High |

| Automation | Increases efficiency by automating the sealing process. | Ready-to-Eat Meals, Desserts | High |

| Hygienic Packaging | Reduces the risk of contamination with sealed packaging. | Bakery Products, Meats | High |

| Extended Market Reach | Better packaging can open up new distribution channels. | Fresh Produce, Seafood | Medium |

| Cost Savings | Reduces waste and lowers packaging costs over time. | Confectionery, Frozen Foods | High |

| Increased First Impressions | Attractive packaging enhances product appeal. | Gift Items, Premium Foods | Medium |

| Flexible Packaging Options | Allows for a variety of packaging styles to meet customer needs. | Catered Meals, Specialty Items | Medium |

| Environmentally Friendly Options | Some machines allow for recyclable or biodegradable materials. | Organic Products, Natural Foods | Low |

| Less Labor-Intensive | Reduces the need for manual labor in packing operations. | All types of products | High |

Streamlined Production Processes and Increased Output with Automation

The implementation of tray sealer packaging machines in a business can drastically streamline production processes and significantly increase output through automation. By minimizing manual intervention, these machines allow companies to achieve higher levels of efficiency, reducing the chances of human error that can arise during traditional packaging methods. The automated nature of tray sealers enables swift and consistent sealing of products, ensuring that each package meets quality standards while maximizing productivity. This efficiency not only accelerates production timelines but also helps businesses to respond more rapidly to market demands.

Moreover, the incorporation of tray sealers into a production line can enhance the overall workflow by integrating seamlessly with other automated processes. This interconnectedness fosters a cohesive environment where production, packaging, and quality control operate in harmony. As a result, businesses can allocate resources more effectively, focusing on innovation and expansion rather than being bogged down by time-consuming manual tasks. The reliability of automated tray sealing fosters a more predictable output, allowing for better inventory management and ultimately leading to improved profitability as businesses scale up operations in a competitive marketplace.

Top 10 Benefits of Using Tray Sealer Packaging Machines

Related Posts

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency

-

Top 5 Blister Sealing Machines for Efficient Packaging Solutions

-

Best Heat Sealing Machine for Blister Packaging 2023 Top Choices for Your Packaging Needs

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging

-

10 Best Eco Blister Packaging Solutions for Sustainable Products in 2023

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs