Top 10 Benefits of Using a Blister Pack Heat Sealer for Your Packaging Needs

In the fast-paced world of packaging, efficiency and security are paramount. The use of a blister pack heat sealer has emerged as a critical solution for businesses aiming to enhance their packaging processes. According to packaging industry expert Dr. Emily Sanders, "Investing in quality blister pack heat sealers not only improves product protection but also boosts overall production efficiency." This statement underscores the importance of adopting advanced sealing technologies to meet the increasing demands of both manufacturers and consumers.

Blister packaging is not merely about aesthetics; it offers practical benefits such as tamper resistance, extended shelf life, and ease of use. As we delve into the top ten benefits of using a blister pack heat sealer, it becomes clear how this equipment transforms the packaging landscape. From reducing waste to ensuring compliance with safety regulations, these tools are becoming indispensable in various sectors, including pharmaceuticals, electronics, and consumer goods.

In today's competitive market, understanding the advantages of a blister pack heat sealer can significantly impact a business's operational success. By exploring the benefits this technology provides, companies can make informed decisions that not only enhance their product packaging but also contribute to their bottom line.

Benefits of Improved Product Protection with Blister Pack Heat Sealers

Blister pack heat sealers have become an essential tool in the packaging industry, particularly for ensuring improved product protection. According to a report by Smithers Pira, the global blister packaging market is expected to reach $10.61 billion by 2024, driven by the need for safer and more efficient packaging solutions. Blister packs, sealed with advanced heat sealers, provide a superior barrier against moisture, light, and air, significantly reducing the risk of contamination and degradation of products. This is particularly crucial for pharmaceuticals and food items where integrity is paramount.

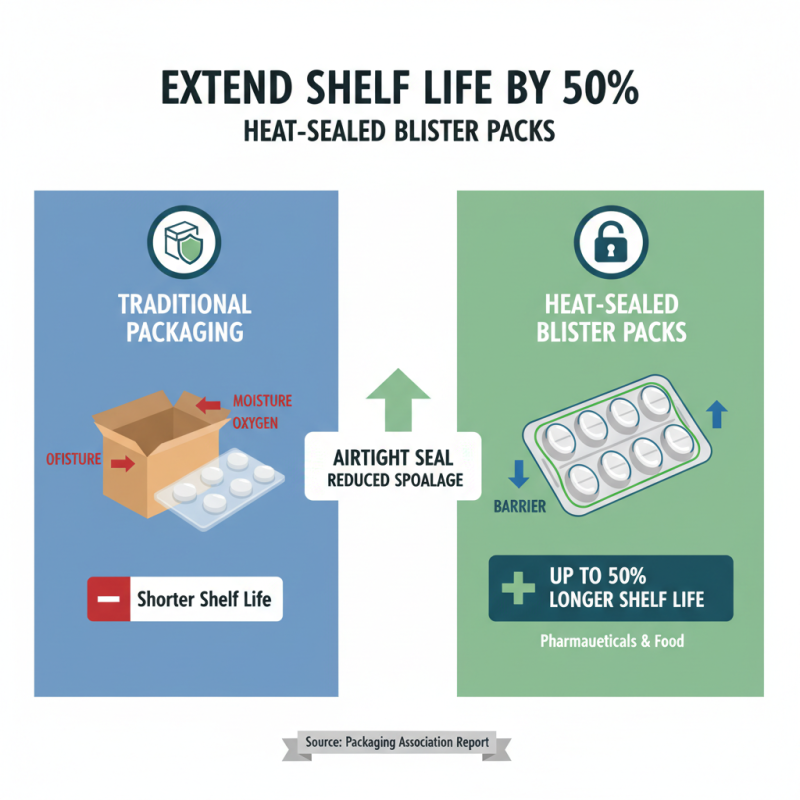

Moreover, the precision offered by blister pack heat sealers contributes to enhanced product shelf life. Research indicates that products packaged in airtight conditions can experience up to a 50% longer shelf life compared to those in traditional packaging. This not only leads to a decrease in spoilage and waste but also strengthens brand trust, as consumers increasingly seek reliable products that maintain their quality over time. As manufacturers shift towards smarter packaging solutions, the role of heat sealers in ensuring optimal product protection cannot be overstated, confirming their necessity in modern packaging strategies.

Top 10 Benefits of Using a Blister Pack Heat Sealer for Your Packaging Needs

Enhanced Shelf Life and Reduced Spoilage Using Heat-Sealed Blister Packs

The shelf life of products directly affects their marketability, especially in industries such as pharmaceuticals and food. According to a report by the Packaging Association, products that utilize heat-sealed blister packs can achieve a shelf life extension of up to 50% compared to those packaged using traditional methods. This significant enhancement is attributed to the airtight seal that heat sealing provides, minimizing exposure to environmental factors such as moisture and oxygen, which are primary contributors to spoilage.

Heat-sealed blister packs also reduce spoilage rates, which is crucial for both manufacturers and consumers. A study conducted by the Food and Drug Administration (FDA) indicated that products packaged with blister technology demonstrated a 30% reduction in spoilage incidents during transportation and storage when compared to standard packaging. This is particularly beneficial for sensitive items; for instance, vitamins and pharmaceuticals are better preserved, leading to lower waste and increased customer satisfaction.

Tip: When utilizing a blister pack heat sealer, ensure you select the correct materials and sealing temperature to achieve the best airtight seal. This will maximize the product's shelf life and minimize spoilage risks.

Tip: Regular maintenance and calibration of your heat sealer machinery can also play a crucial role in maintaining the consistency and integrity of the seals, ensuring each product is adequately protected against spoilage throughout its shelf life.

Cost Efficiency in Packaging Through Blister Pack Heat Sealing Technology

Blister pack heat sealing technology offers significant cost efficiency that can greatly benefit businesses in the packaging sector. According to a recent industry report, companies can achieve up to a 25% reduction in packaging costs by transitioning to heat sealing methods. This reduction arises mainly from decreased material waste, as blister packs can be precisely designed to fit products, minimizing excess packaging. Additionally, the longevity and protective qualities of heat-sealed blister packs can extend the shelf life of products, reducing losses from spoilage or damage.

Implementing blister pack heat sealing not only conserves materials but also streamlines the production process. Businesses can see increased throughput, allowing for faster output without compromising quality. A study by a leading packaging solutions firm indicated that manufacturers leveraging heat sealing saw an increase in production efficiency by as much as 30%. This efficiency translates to better resource allocation and lower operational costs, ultimately benefiting the bottom line.

Tips: When considering the switch to blister pack heat sealing, assess your design needs carefully. Customizing your blister packs to fit your products precisely can significantly enhance materials savings. Additionally, regularly maintaining your heat sealing equipment can prevent downtime and ensure consistent quality, further optimizing cost efficiencies.

Top 10 Benefits of Using a Blister Pack Heat Sealer for Your Packaging Needs

| Benefit | Description | Cost Efficiency |

|---|---|---|

| Improved Product Protection | Blister packs effectively shield products from external elements, reducing damage. | Reduces return costs due to damaged goods. |

| Increased Shelf Life | Sealed packs prolong the freshness of products, especially pharmaceuticals. | Minimizes waste and loss due to spoilage. |

| User-Friendly Design | Blister packs are easy for consumers to open, improving user experience. | Encourages repeat purchases and customer loyalty. |

| Customization Options | Flexibility in design allows for branding and product information. | Enhances marketing efforts, leading to increased sales. |

| Space Efficiency | Compact design saves storage space and shipping costs. | Lowers overall logistics expenses. |

| Regulatory Compliance | Blister packs can meet safety and regulatory requirements. | Reduces potential fines and legal costs. |

| Reduced Labor Costs | Automation in sealing processes decreases labor needs. | Saves on long-term workforce expenses. |

| Environmental Considerations | Materials can be chosen to be recyclable or biodegradable. | Attracts eco-conscious consumers, broadening market appeal. |

| Efficient Production | Streamlined processes enhance production speed and efficiency. | Lowers per-unit costs, improving profit margins. |

| Enhanced Product Appeal | Aesthetic designs make products visually attractive to consumers. | Increases the likelihood of purchase and market competitiveness. |

User-Friendly Packaging Solutions: Convenience and Accessibility for Consumers

Blister pack heat sealers provide a user-friendly solution that enhances the accessibility of packaged products for consumers. These devices enable manufacturers to create tamper-evident, secure packaging that keeps products safe while remaining easy to open. The convenience of blister packs allows consumers to see the product through the transparent plastic, helping them make informed purchasing decisions right at the point of sale. Moreover, the lightweight nature of blister packaging makes it a practical choice for both manufacturers and consumers, reducing shipping costs and simplifying logistics.

When using a blister pack heat sealer, it's important to consider a few tips to maximize efficiency. First, ensure that the machine is calibrated correctly to achieve optimal sealing results, which will prevent any product damage or leaks. Second, keep the workspace organized to quicken the sealing process and maintain a steady flow of packaging. Lastly, utilize the proper materials, such as compatible films and trays, to achieve the desired durability and aesthetics for your products.

The ease of access provided by blister packs also enhances user experience. Designs that can be opened with minimal effort cater to a wide range of consumers, including seniors and those with disabilities. Furthermore, incorporating clear instructions within the packaging can significantly boost customer satisfaction by ensuring they can access the product without frustration. By prioritizing accessibility and convenience, companies can enhance their brand reputation and foster customer loyalty.

Sustainability Advantages: Eco-Friendly Practices in Blister Packaging Solutions

Blister packaging has gained significant attention in recent years, particularly for its sustainability advantages. As eco-conscious practices become increasingly important, businesses are turning to blister pack heat sealers that not only enhance product safety but also support environmentally friendly initiatives. These sealers enable the use of recyclable materials, which minimizes waste and reduces the carbon footprint associated with traditional packaging methods. By opting for materials that can be easily recycled, manufacturers can contribute to a circular economy, ensuring that packaging serves a dual purpose—protecting products while being kinder to the planet.

Moreover, the efficiency of blister pack heat sealers plays a crucial role in promoting sustainable practices. These machines often require less energy compared to older packaging methods, resulting in lower operational costs and reduced environmental impact. The precise sealing capabilities minimize the use of excess material, further enhancing resource conservation. Enhanced production efficiency not only streamlines the manufacturing process but also assures that companies can meet their sustainability goals without compromising on product quality. Embracing blister packaging solutions, therefore, becomes a strategic move for businesses looking to align their operations with eco-friendly philosophies while catering to a growing environmentally aware consumer base.

Related Posts

-

How to Choose the Best Blister Pack Heat Sealer for Your Packaging Needs

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

-

How to Choose the Best Plastic Tray Sealing Machine for Your Business

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency