Best Heat Sealing Machine for Blister Packaging 2023 Top Choices for Your Packaging Needs

In the ever-evolving landscape of packaging technology, the demand for effective and reliable solutions is increasing significantly. According to a recent market analysis by Smithers Pira, the global packaging market is projected to reach USD 1.1 trillion by 2025, creating an urgent need for advanced machinery that can meet various packaging specifications. Among these, the heat sealing machine for blister packaging has emerged as a vital component, ensuring product protection and enhancing shelf life, which is crucial in sectors such as pharmaceuticals and consumer goods.

As we look ahead to 2023, numerous options are available, ranging from manual to fully automated machines that cater to businesses of all sizes. The growing trend of sustainability and regulatory requirements in packaging solutions further emphasizes the importance of investing in high-quality heat sealing machines. Industry reports indicate that advancements in technology, including precise temperature control and improved sealing techniques, contribute remarkably to reducing production waste and enhancing efficiency, making these machines an indispensable asset for manufacturers aiming to stay competitive. This article will explore the best heat sealing machines for blister packaging, evaluating their features, performance, and suitability for your specific packaging needs in the coming years.

Top Criteria for Choosing the Best Heat Sealing Machine in 2023

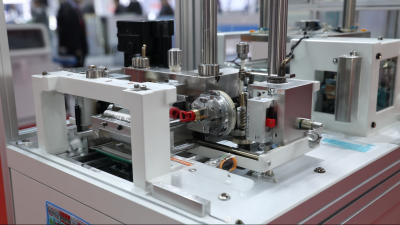

When selecting the best heat sealing machine for blister packaging in 2023, it's essential to consider several critical criteria that can significantly impact your packaging efficiency and product protection. First and foremost, the machine's sealing temperature and time control are vital. Accurate temperature settings ensure that the heat sealing process forms a strong bond without damaging the product, while precise timing helps maintain consistency across batches.

Another key factor is the machine's compatibility with various materials. Different packaging materials may require specific heat sealing methods, so it's important to choose a machine that can handle a range of films and foils. Additionally, the machine’s ease of use and maintenance should not be overlooked. A user-friendly interface and straightforward cleaning processes can save precious time and reduce labor costs, making your operations more efficient.

Lastly, consider the machine's production capacity and footprint. For businesses with varying production needs, a versatile heat sealing machine that can adapt to different output levels is advantageous. Compact designs can also optimize space in manufacturing environments, making it easier to integrate the machine into existing workflows.

Heat Sealing Machines Performance Comparison 2023

This chart compares the performance of different heat sealing machines based on key metrics such as sealing speed (packages per minute), sealing width (millimeters), and energy consumption (watts). These factors are critical when selecting the best heat sealing machine for blister packaging needs.

Key Features of Blister Packaging and Their Impact on Efficiency

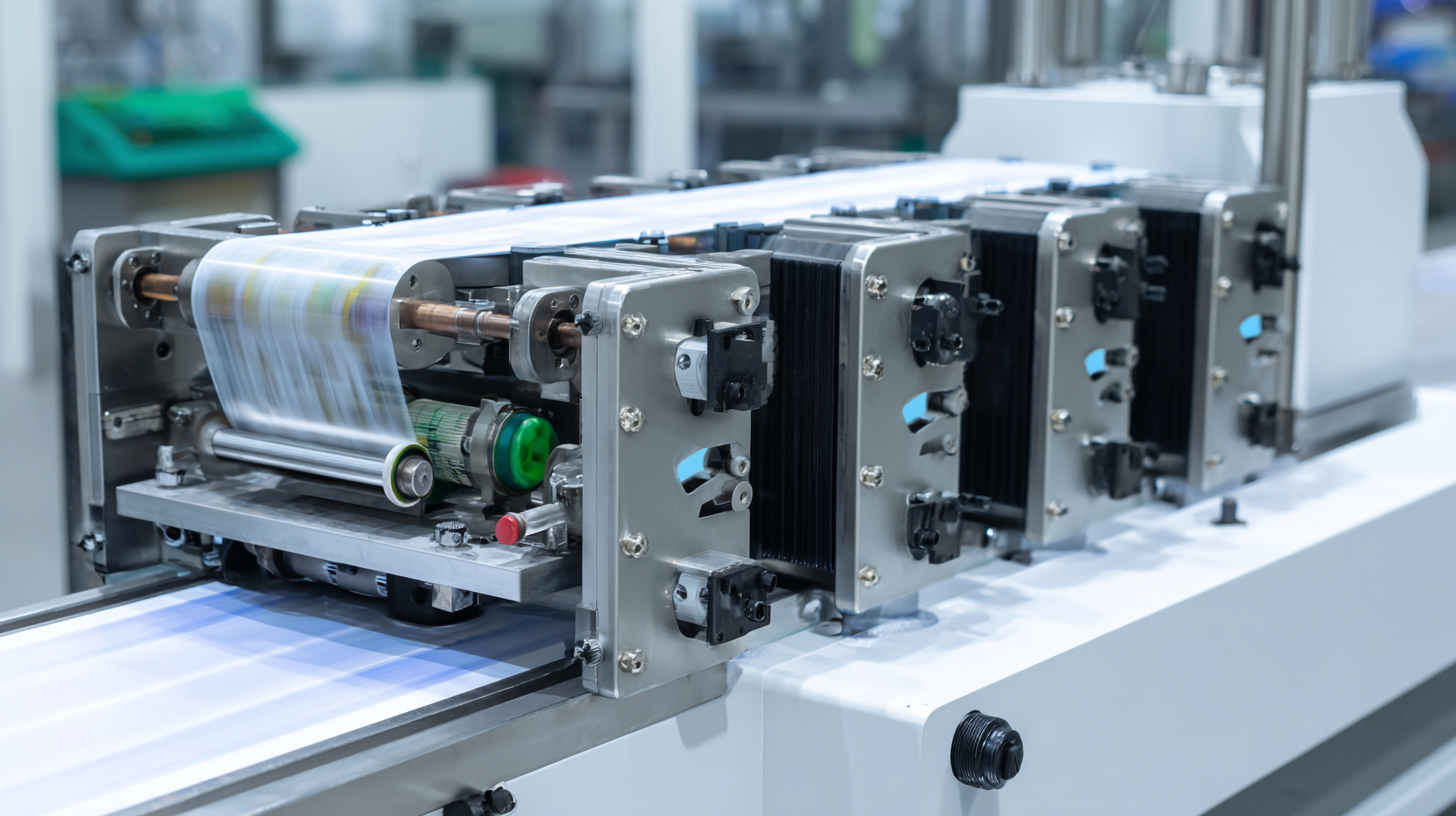

Blister packaging is increasingly recognized for its efficiency and effectiveness in protecting products, particularly in the pharmaceutical and consumer goods sectors. The key features of blister packaging include its ability to provide a barrier against moisture, light, and oxygen, which are critical factors in maintaining the integrity of sensitive products. This protective capability not only enhances the shelf life of such items but also allows for increased automation in the packaging process, ultimately reducing labor costs and boosting production efficiency.

As companies like Bayer introduce innovative materials, such as PET for blister packs, the industry is set to benefit from enhanced sustainability and performance. The shift toward sustainable materials, combined with advancements in automation and digital technology, presents significant opportunities for growth in the blister packaging equipment market.

Manufacturers and brands can capitalize on these trends to improve their packaging solutions, align with consumer preferences for environmentally friendly products, and streamline their operations, thereby achieving better overall efficiency and effectiveness in their packaging needs.

Market Trends: Growth Projections for Heat Sealing Machine Industry by 2025

The heat sealing machine industry is poised for significant growth in the coming years, with projections indicating a strong upward trajectory. According to a recent market analysis, the global market for heat sealing equipment is expected to witness substantial advancements, driven by increasing demand across various sectors, including packaging, food, and pharmaceuticals. The overall trends suggest that innovative technologies and enhanced efficiencies will play a pivotal role in shaping the market's future, aligning with shifting consumer preferences towards more sustainable and efficient packaging solutions.

In particular, the die cut lids market appears robust, with expectations to reach a valuation of USD 1,840.5 million by 2034, growing at a compound annual growth rate (CAGR) of 7.3%. This indicates a burgeoning demand for precision and customization in packaging solutions. Similarly, other segments, such as tray sealing machines, are projected to expand from USD 1.29 billion in 2024 to USD 1.64 billion by 2030, reflecting the industry's adaptability to meet evolving market needs and the rise of eco-friendly packaging alternatives. As the sector progresses, stakeholders will need to focus on technological advancements to maintain competitiveness and respond effectively to market dynamics.

Comparative Analysis of Leading Heat Sealing Machines for Blister Packaging

In 2023, the selection of the best heat sealing machines for blister packaging has become increasingly critical as industries seek to optimize efficiency and packaging integrity. Recent studies highlight the importance of seal materials in flexible food packaging, emphasizing the need for advanced heat seal coatings to ensure robust seal integrity. For instance, a review indicated that the right specifications for heat seal lacquers significantly influence the quality of blister packages. Factors such as the thickness of the heat seal lacquer can affect the adhesion and overall performance of the packaging, which is vital for maintaining product safety and extending shelf life.

The market for heat sealing machines is also showing an upward trajectory. According to a market research study, the global die cut lids market is projected to grow to USD 1,840.5 million by 2034, at a compound annual growth rate (CAGR) of 7.3%. This growth indicates a robust demand for reliable heat sealing solutions tailored for blister packaging applications. It is essential to consider these industrial advancements while selecting machinery, as efficiency and technological innovation can significantly enhance packaging outcomes, addressing both performance and environmental concerns in today's eco-conscious market.

Best Heat Sealing Machine for Blister Packaging 2023

| Model | Seal Width (inches) | Production Speed (units/min) | Heat Time (seconds) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 12 | 30 | 2 | 50 | 1500 |

| Model B | 10 | 25 | 3 | 45 | 1200 |

| Model C | 14 | 35 | 1.5 | 55 | 1800 |

| Model D | 16 | 40 | 2.5 | 60 | 2000 |

Maintenance and Operational Costs of Heat Sealing Machines in the Packaging Sector

When considering the maintenance and operational costs of heat sealing machines in the packaging sector, several factors come into play that can significantly influence a company's bottom line. Regular maintenance is crucial to ensure efficiency and longevity of the equipment. Components such as sealing bars and temperature regulators must be inspected frequently to prevent costly downtime and repairs. Implementing a maintenance schedule can lead to long-term savings and better operational reliability.

Operational costs are driven by energy consumption and the materials used in the packaging process. Heat sealing machines can utilize a substantial amount of electricity, especially in high-volume production settings. Companies can mitigate these costs by investing in energy-efficient models and optimizing their processes to reduce waste. Moreover, the choice of packaging materials can also impact overall expenses, as some materials may require specific sealing techniques or additional resources, thus increasing operational complexity and costs.

Related Posts

-

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

Unlocking Efficiency: The Future of Blister Packaging Equipment in Modern Manufacturing

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Innovative Heat Sealing Machine for Blister Packaging Revolutionizes Industry Trends at 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business