5 Best Packaging Systems for Streamlining Your Business Operations

In today's competitive market, optimizing business operations is more crucial than ever, and one of the key components of this optimization is the effective implementation of packaging systems. According to a report by Smithers Pira, the global packaging market is expected to reach $1 trillion by 2024, driven by advancements in technology and increasing demand for efficient supply chain solutions. Packaging systems not only enhance product protection but also improve logistical efficiency, with studies indicating that businesses can reduce shipping costs by up to 20% through better packaging strategies.

As companies continually strive to improve operational efficiency and customer satisfaction, exploring the best packaging systems available is essential for achieving seamless workflows and ensuring products reach consumers in optimal condition. This blog will delve into the five best packaging systems designed to streamline your business operations and drive success.

Identifying the Key Features of Advanced Packaging Systems for Modern Businesses

In today's fast-paced business environment, advanced packaging systems have become essential for enhancing operational efficiency. Key features that modern businesses should seek include automation, real-time tracking, and sustainable materials. According to a report by Mordor Intelligence, the global automated packaging market is projected to grow at a CAGR of 14.3% from 2021 to 2026, indicating a significant shift towards automated solutions that facilitate speed and accuracy in packaging processes.

Additionally, real-time tracking capabilities allow businesses to monitor packaging and shipping progress, reducing delays and improving customer satisfaction. A study by ResearchAndMarkets highlights that 70% of consumers are willing to pay more for better delivery options, underscoring the need for businesses to invest in packaging systems that provide transparency and efficiency. Furthermore, the emphasis on sustainability cannot be ignored; reports from Grand View Research indicate that the sustainable packaging market is expected to reach $500 billion by 2028. As businesses pursue eco-friendly practices, adopting packaging systems that utilize recyclable and biodegradable materials has become a critical factor in meeting consumer expectations and regulatory requirements.

Comparative Analysis of Cost Efficiency in Leading Packaging Solutions

In the competitive landscape of modern business, the efficiency of packaging systems can significantly influence operational costs and overall productivity. According to a recent report by Smithers Pira, the global packaging market is expected to reach $1 trillion by 2024, underscoring the critical role that cost-effective solutions play in enhancing business performance. When evaluating packaging systems, companies must consider not only the upfront costs but also the long-term savings generated through automation and reducing waste.

A comparative analysis of leading packaging solutions reveals that automated packaging machinery can reduce labor costs by up to 30% while also increasing throughput. For instance, the use of stretch film packaging systems can lead to material savings of around 15%, as highlighted in a study by Freedonia Group. Additionally, reports from Packaging Strategies indicate that companies implementing integrated packaging solutions see an average reduction of 20% in operational expenses, showcasing the benefits of investing in advanced packaging technologies. These insights clearly demonstrate that a strategic approach to packaging can streamline operations and significantly enhance cost efficiency.

Cost Efficiency of Packaging Systems

Exploring the Impact of Automation in Streamlining Packaging Processes

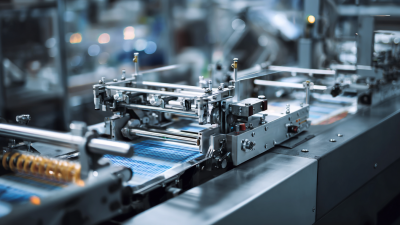

The integration of automation in packaging processes has transformed the way businesses operate, significantly enhancing efficiency and productivity. Automated packaging systems reduce manual labor, minimize human errors, and speed up production times. By utilizing advanced technologies such as robotics and smart conveyor systems, businesses can optimize their packaging lines to handle varying product sizes and complexities. This flexibility is essential in catering to fluctuating market demands and improving overall operational agility.

Furthermore, automated packaging solutions enable real-time tracking and data collection, allowing companies to monitor performance metrics closely. This transparency helps identify bottlenecks and areas for improvement, ultimately contributing to informed decision-making and strategic planning. As a result, companies can streamline their supply chains, reduce waste, and deliver products to market more swiftly. Embracing automation not only enhances packaging processes but also positions businesses to thrive in an increasingly competitive landscape.

Case Studies: Businesses That Achieved Growth through Innovative Packaging Systems

In the rapidly evolving landscape of global business, innovative packaging systems have emerged as powerful tools for growth and efficiency. For instance, case studies from the Henan Free Trade Zone reveal how businesses have successfully implemented novel logistics models that integrate air and land transportation. These strategies not only streamline operations but also enhance speed and reliability in the supply chain, setting a benchmark for others to follow.

Businesses looking to adopt similar innovations should consider the following tips: First, invest in research to identify packaging technologies that can elevate your operational efficiency. Whether through smart packaging or automation, the right choice can lead to significant time and cost savings. Second, engage with case studies from the Henan Free Trade Zone to understand the practical application of these systems. Learning from successful companies can provide insights and inspire creative solutions tailored to your unique business needs. Finally, remain adaptable to changing market demands by regularly evaluating your packaging strategies in light of emerging trends in the sector.

By prioritizing innovative packaging solutions, businesses will not only keep pace with the growing market but also pave the way for sustainable growth in an increasingly competitive environment.

5 Best Packaging Systems for Streamlining Your Business Operations

| Packaging System | Business Type | Key Benefits | Growth Achieved |

|---|---|---|---|

| Automated Shrink Wrapping | E-commerce Retailer | Increased efficiency, Reduced labor costs | 30% growth in sales |

| Custom Box Design Software | Food Manufacturer | Enhanced customer experience, Better brand visibility | 25% increase in market share |

| Eco-Friendly Packaging Solutions | Cosmetics Company | Sustainability appeal, Lower shipping costs | 40% growth in customer base |

| Flexible Packaging Technology | Snack Food Company | Longer shelf life, Reduced waste | 20% revenue growth |

| Smart Packaging with QR Codes | Beverage Company | Consumer engagement, Improved traceability | 35% increase in brand loyalty |

The Future of Packaging Technology: Trends Shaping Efficiency and Sustainability

The future of packaging technology is increasingly shaped by sustainability, as businesses seek to align their operations with eco-friendly practices. By adopting sustainable packaging solutions, companies not only minimize their environmental footprint but also enhance their brand image and reduce costs. This trend is evident in the significant projected growth of the global aseptic packaging market, expected to reach $9.67 billion in 2024 and $19.41 billion by 2032, reflecting a compound annual growth rate of 9.1%. The integration of sustainable materials and practices in packaging is becoming a crucial component of operational efficiency.

Minimalism is another trend emerging in packaging technology, advocating for simplicity and efficiency through the ethos of "less is more." This approach encourages businesses to eliminate unnecessary elements, thereby reducing waste and streamlining processes. The projected expansion of the sustainable packaging equipment market, expected to exceed $157.6 billion by 2024 with a CAGR of over 7.3% until 2034, highlights the growing demand for innovative solutions that cater to both environmental concerns and market efficiency. As the logistics industry evolves, incorporating AI-driven warehousing and green delivery solutions will further enhance the ability of companies to operate sustainably while meeting the increasing demands of e-commerce and the packaging goods market.

Related Posts

-

How to Choose the Right Packaging Systems for Your Business Needs

-

Innovative Examples of Packaging Equipment Transforming Global Supply Chains

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business

-

7 Essential Tips for Choosing the Right Food Packaging Machine for Your Business

-

Common Issues Faced by Businesses Using Food Packaging Machine