7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

In the fast-paced world of packaging, maximizing the efficiency of your blister sealing machine is essential for maintaining a competitive edge. As industries strive for higher productivity and cost-effectiveness, implementing best practices becomes imperative.

This article explores seven key strategies that can significantly enhance the performance of your blister sealing machine. From optimizing machine settings to ensuring proper maintenance and training for operators, each practice is aimed at minimizing downtime and increasing throughput. By applying these best practices, businesses can not only streamline their operations but also improve product quality and reduce waste. Embracing these recommendations will empower manufacturers to achieve their operational goals while delivering optimal results in blister packaging processes.

Best Practices for Conducting Regular Maintenance on Blister Sealing Machines

Regular maintenance of blister sealing machines is crucial to ensure optimal efficiency and longevity. According to industry reports, machines that receive consistent upkeep can achieve up to 20% higher productivity than those that undergo infrequent maintenance. Components such as sealing jaws, temperature controllers, and vacuum pumps require routine inspections to prevent costly downtime. A study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that neglecting maintenance can lead to an increase in malfunction rates by as much as 30%, directly impacting the overall production output.

To maximize the efficiency of your blister sealing machine, it’s essential to adopt a systematic maintenance schedule. Tips to consider include creating a daily checklist for operators to monitor performance metrics and identify potential issues early. Additionally, developing a quarterly deep cleaning routine can help prevent the buildup of debris and particles that could hinder mechanical performance. Finally, keeping a log of all maintenance activities can facilitate better tracking of machine performance over time, enabling more informed decisions about future improvements.

Key Metrics for Measuring the Efficiency of Blister Sealing Operations

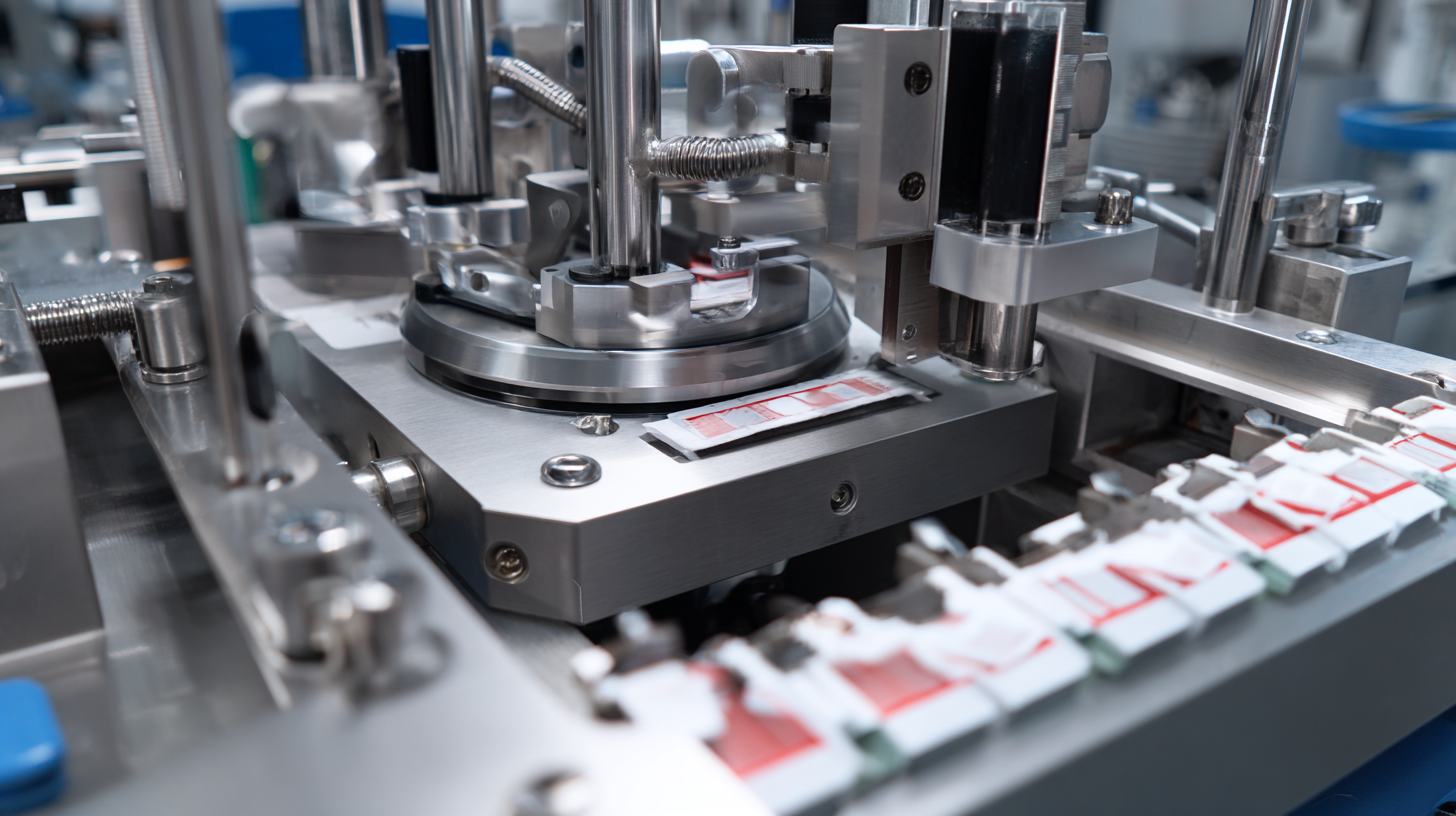

Measuring the efficiency of blister sealing operations is crucial for identifying areas of improvement and maximizing productivity. Key metrics to focus on include cycle time, which refers to the time taken to complete one blister sealing operation. By analyzing cycle time, manufacturers can determine bottlenecks in the process and implement strategies to reduce delays. Regular monitoring can also help ensure consistency in production speeds, enabling better planning and resource allocation.

Another important metric is yield rate, which measures the percentage of correctly sealed blisters out of the total produced. A high yield rate indicates effective operations, while a low yield rate may highlight issues in machine settings or material quality. Investigating root causes for defects can lead to improved protocols, ultimately enhancing overall efficiency. Additionally, monitoring equipment downtime is vital; tracking the frequency and duration of machine stoppages helps identify maintenance needs and minimizes unexpected interruptions during production runs. By focusing on these key performance indicators, operators can refine their blister sealing processes and achieve greater operational efficiency.

Importance of Material Selection in Enhancing Sealing Performance

The importance of material selection in enhancing the sealing performance of blister sealing machines cannot be overstated. Choosing the right materials directly impacts the integrity of the seal, which is critical in maintaining product quality, especially in the pharmaceutical and food packaging industries. According to a report by Smithers Pira, improper material choices can lead to a 5-15% increase in defective seals, resulting in significant financial losses and potential health risks.

Utilizing materials with optimal thermal properties and compatibility with sealing techniques, such as medical-grade PVC or high-barrier films, can significantly enhance sealing efficacy. Research has shown that films designed with specific sealing temperatures can improve seal strength by up to 20%. Additionally, considering the moisture barrier properties and chemical resistance of the materials ensures that the products are well-protected throughout their shelf life.

These strategic material selections not only improve the functionality of blister packaging but also align with sustainability goals, reducing waste in the long run. Thus, investing time and resources into selecting appropriate materials can lead to improved efficiency and reliability of blister sealing machines.

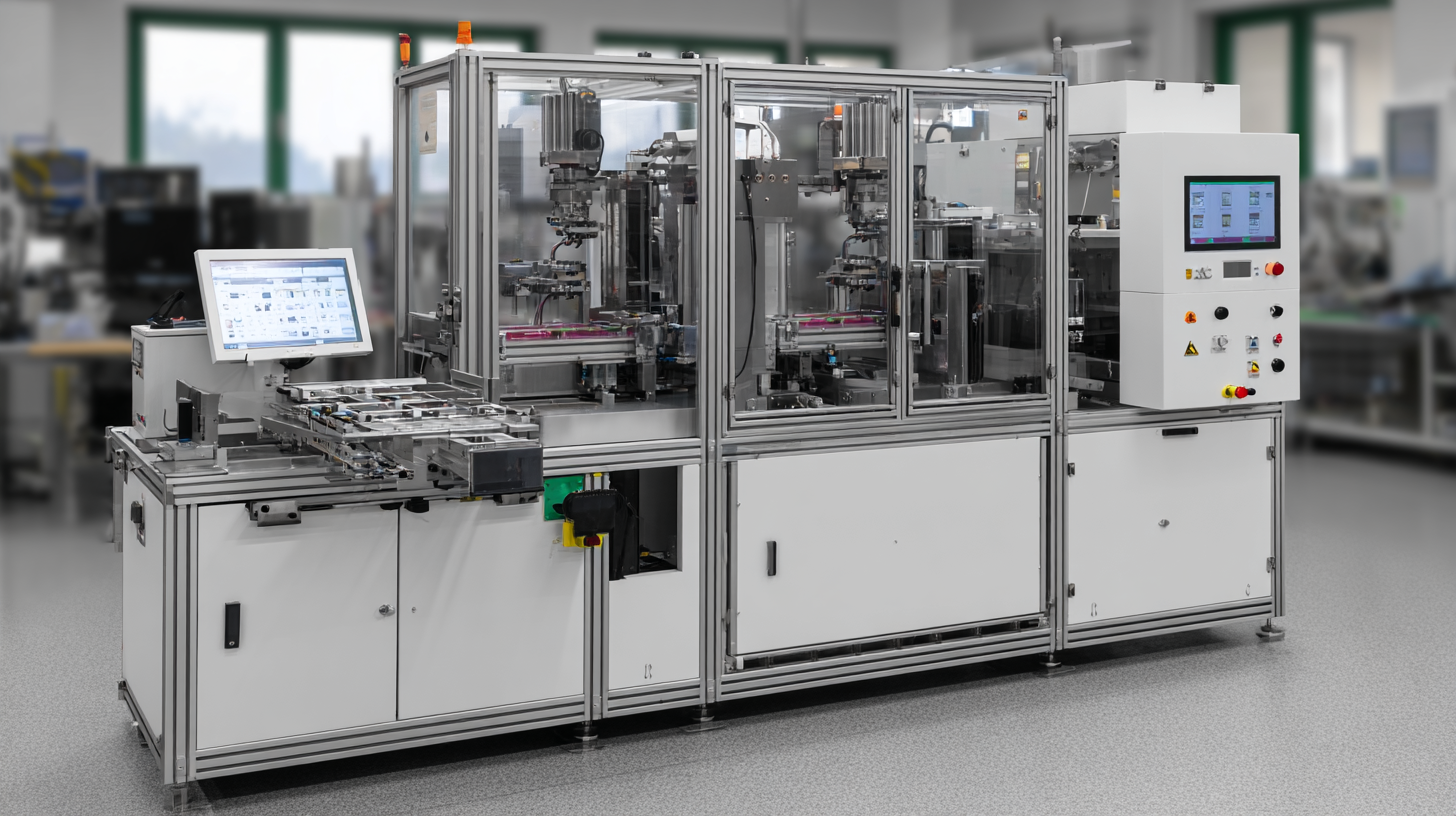

Utilizing Automation to Optimize Blister Sealing Processes and Reduce Downtime

Automation plays a crucial role in enhancing the efficiency of blister sealing processes, primarily by minimizing human intervention and reducing the likelihood of errors. By integrating automated systems, manufacturers can achieve consistent sealing quality, which significantly improves production rates. Automated machines not only streamline the sealing process but also enable real-time monitoring, allowing for immediate adjustments based on performance data. This adaptability ensures that any potential issues are addressed promptly, thereby reducing downtime and increasing overall productivity.

Additionally, automation allows for the implementation of predictive maintenance strategies. By utilizing sensors and analytics, manufacturers can predict when a machine is likely to fail or require maintenance, preventing unexpected breakdowns that lead to costly downtime. This proactive approach not only extends the life of the blister sealing machine but also ensures a smoother production flow.

Ultimately, leveraging automation in blister sealing processes is essential for companies aiming to optimize efficiency, cut costs, and maintain a competitive edge in the market.

Employee Training Programs: Essential for Maximizing Blister Sealer Efficiency

Employee training programs play a crucial role in maximizing the efficiency of blister sealing machines in pharmaceutical operations. As the industry seeks to enhance productivity and reduce operational costs, well-designed training initiatives can significantly impact machine performance and product quality. By equipping employees with the necessary skills and knowledge, companies can ensure seamless operation of sealing equipment, reducing downtime and minimizing errors.

Furthermore, investing in training not only optimizes the use of blister sealers but also aligns with broader industry benchmarks. Research indicates that by improving the efficiency of average drug manufacturers to match that of the top-performing companies, significant labor and unit-cost savings can be realized. This highlights the importance of continuous employee development, as a skilled workforce directly contributes to enhanced operational outcomes, leading to better overall performance in pharmaceutical manufacturing processes.

Related Posts

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

-

Unlocking the Future of Packaging Automation with Digital Innovations

-

Common Issues Faced by Businesses Using Food Packaging Machine

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency

-

How to Choose the Right Plastic Tray Sealing Machine for Your Business Needs