How to Choose the Best Tray Sealing Machine for Your Packaging Needs

When it comes to packaging processes, selecting the right machinery is crucial for optimizing efficiency and ensuring product integrity. As the industry evolves, the importance of a high-quality tray sealing machine cannot be overlooked. According to industry expert, John Smith, a renowned packaging consultant, “Investing in a reliable tray sealing machine can significantly enhance your production line, providing both speed and quality that meets the market demands.”

In this competitive landscape, businesses must navigate various options to find a tray sealing machine that aligns with their specific packaging needs. Factors such as material compatibility, sealing speed, and overall machine reliability play pivotal roles in making this decision. Understanding these elements will not only streamline operations but also improve end-user satisfaction and product shelf life.

As we delve into the intricacies of selecting the best tray sealing machine for your packaging needs, we will explore key considerations and expert insights that will guide you in making an informed choice, regardless of your industry demands.

Understanding Tray Sealing Machines and Their Functionality

Tray sealing machines play a crucial role in modern packaging solutions, particularly in food and pharmaceutical industries. These machines are designed to seal products in trays using heat and vacuum technology, ensuring freshness and extending shelf life. According to a report by Grand View Research, the global tray sealing machine market is expected to reach USD 1.27 billion by 2025, indicating a growing demand for efficient packaging methods. The functionality of these machines varies, with options for manual, semi-automatic, and fully automatic systems, allowing businesses to select a model that best suits their operational scale and needs.

When choosing a tray sealing machine, it's essential to consider the specific requirements of your products. Factors such as material compatibility, sealing time, and energy efficiency can significantly impact performance and cost-effectiveness. For example, machines that use heat sealing can accommodate a variety of materials, from plastics to flexible films. Incorporating advanced features like programmable controls can enhance operational flexibility and precision.

**Tips:** Always evaluate your production volume and product type before making a purchase decision. For smaller operations, a semi-automatic machine may suffice, while high-volume producers could benefit from fully automatic systems. Additionally, ensuring compliance with food safety standards is vital, as this will not only safeguard your products but also enhance your brand reputation. Consider seeking expert guidance or consulting with industry reports to make an informed decision tailored to your packaging needs.

Tray Sealing Machine Comparison

Key Factors to Consider When Choosing a Tray Sealing Machine

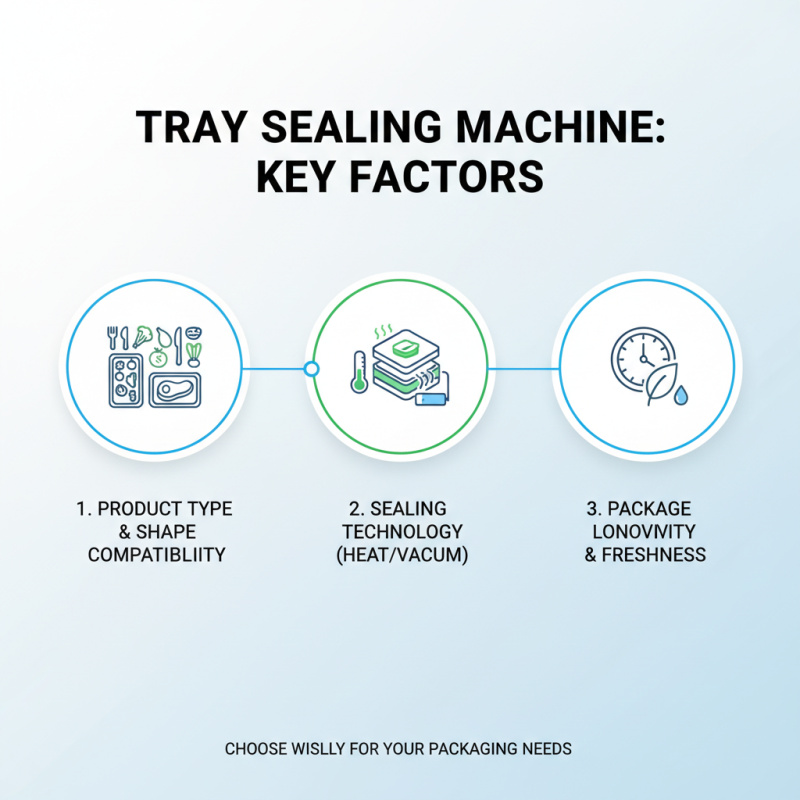

When choosing a tray sealing machine, several key factors should be considered to ensure that it meets your packaging needs effectively. First, the type of product you plan to package plays a crucial role in your decision. Different machines are designed to handle various materials and product shapes, so it's important to choose one that is compatible with your specific items. Additionally, consider the machine's sealing technology—whether it uses heat or vacuum sealing—as this will affect both the longevity of the package and the freshness of the product inside.

Another significant factor is the machine's production capacity. Assess your production scale to select a machine that can efficiently handle your volume without compromising speed or quality. Furthermore, ease of operation and maintenance should not be overlooked; a user-friendly interface can facilitate training and minimize downtime. Finally, consider the machine's size and footprint, especially if space is limited in your facility. By evaluating these criteria, you can make an informed choice that aligns with your organization's packaging requirements.

Types of Tray Sealing Machines and Their Applications

When selecting a tray sealing machine, understanding the various types and their specific applications is crucial for effective packaging solutions. One common type is the manual tray sealing machine, which is ideal for small to medium-sized businesses that require a flexible, cost-effective option. These machines allow operators to place trays manually, making them suitable for businesses that have low to moderate production volumes. Manual machines are often used in food service settings for packaging individual meals or catering trays, as they provide good sealing quality without the need for extensive automation.

In contrast, automatic tray sealing machines are designed for higher output and efficiency. They are perfect for large-scale operations where speed is essential. These machines can handle different packaging materials and are equipped with advanced features such as temperature control and vacuum sealing, making them suitable for various industries, including food production and medical supplies. Additionally, some models include die-cutting and embossing capabilities, which can enhance product presentation. By choosing a machine that aligns with production volume and specific packaging needs, businesses can optimize their operations and improve product shelf life.

Evaluating Production Capacity and Efficiency for Your Needs

When selecting a tray sealing machine, understanding your production capacity and efficiency needs is paramount. Analyzing your output requirements begins with assessing the volume of products you plan to package. Consider peak production times and the average daily volume to ensure the machine can handle fluctuations seamlessly. High-capacity machines are ideal for large-scale operations, while smaller units may suffice for boutique or low-volume production.

Additionally, efficiency plays a critical role in maximizing your investment. A machine that provides quick setup times and reduces changeover periods can greatly enhance workflow. Look for features like adjustable sealing parameters that allow you to switch between different product types without extensive downtime.

**Tips:**

- Always perform a trial run with potential machines to gauge their speed and efficiency before making a purchase.

- Evaluate the energy consumption of the machine; efficient models can reduce operational costs significantly over time.

- Consider the type of materials used for sealing as well; certain machines perform better with specific materials, impacting both effectiveness and cost.

How to Choose the Best Tray Sealing Machine for Your Packaging Needs

| Feature | Machine A | Machine B | Machine C |

|---|---|---|---|

| Production Capacity (trays/hour) | 300 | 500 | 400 |

| Efficiency (%) | 85 | 90 | 88 |

| Power Consumption (kW) | 2.5 | 3.0 | 2.8 |

| Footprint (sq ft) | 15 | 20 | 18 |

| Weight (lbs) | 350 | 450 | 400 |

| Price ($) | 10,000 | 12,000 | 11,000 |

Budgeting for Your Tray Sealing Machine Purchase and Maintenance Costs

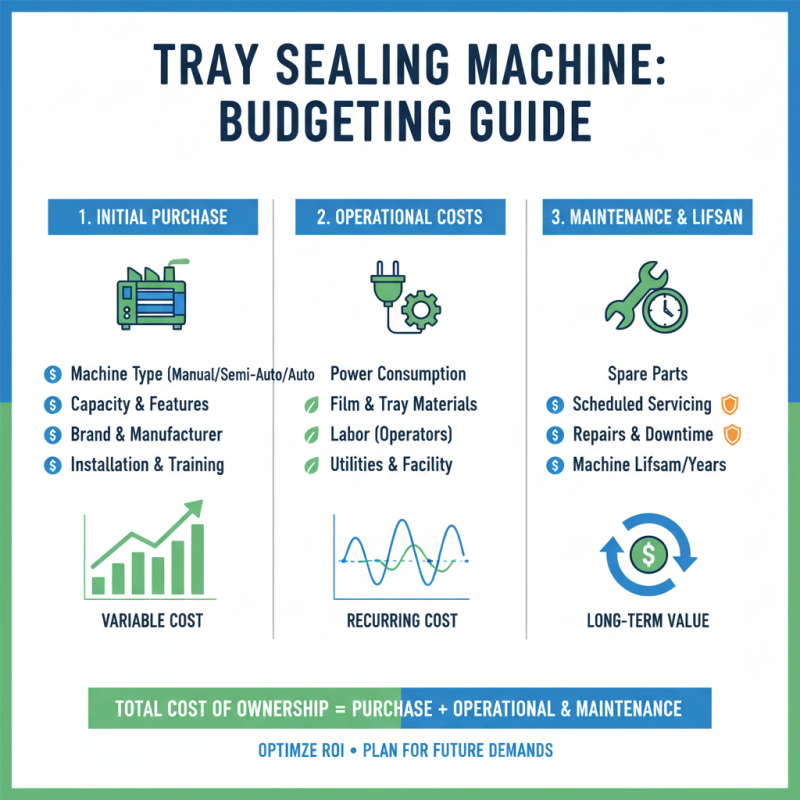

When budgeting for your tray sealing machine, it’s essential to consider not only the initial purchase price but also the ongoing maintenance and operational costs. The initial investment can vary greatly depending on the machine's features, capacity, and automation level. A thorough assessment of your production needs will help you select a machine that provides the best return on investment while ensuring sufficient flexibility for future demands.

Beyond the purchase cost, maintenance expenses should also factor into your budget. Regular maintenance is crucial for the longevity of your tray sealing machine and can prevent costly repairs down the line. This includes routine inspections, necessary replacements of worn components, and the cost of any consumables that the machine may require. Additionally, it’s wise to allocate funds for employee training to ensure that staff are well-versed in operating and maintaining the equipment effectively, maximizing productivity and reducing the likelihood of downtime.

Related Posts

-

How to Choose the Right Packaging Systems for Your Business Needs

-

Exploring the Future of Packaging Systems at China Import and Export Fair 2025: Insights and Innovations

-

Revolutionizing Sustainability: The Future of Thermoformed Plastic Packaging Solutions

-

10 Best Automated Packaging Solutions for Streamlining Your Business

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

7 Compelling Reasons to Choose Tray Packaging for Your Business Success