2026 How to Choose the Best Packaging Sealing Machine for Your Business?

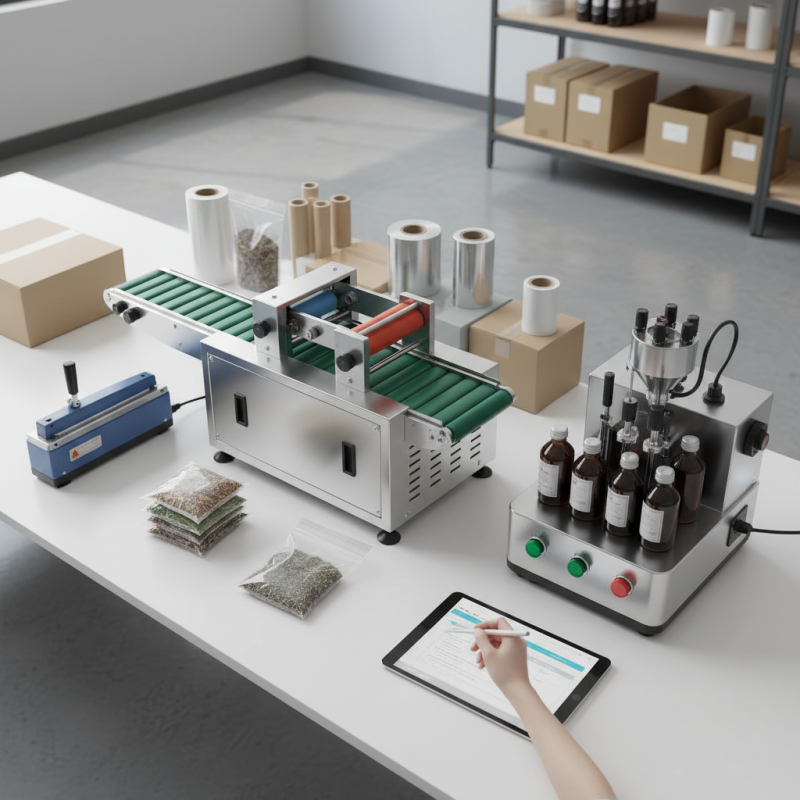

Choosing the right packaging sealing machine is crucial for any business. It affects product safety, shelf life, and overall presentation. With various options on the market, making the best choice can be overwhelming.

Consider your specific needs. Do you package liquids or solids? Different machines cater to different products. Additionally, reflect on the scale of your operations. A small business may not need the same machine as a large manufacturer. Each choice comes with its pros and cons.

It's important to research thoroughly. Not all machines are created equal. Some may lack the necessary efficiency or durability. Read customer reviews and gather insights from other users. This process can help you avoid costly mistakes. Making an informed decision is essential for your success.

Understanding the Different Types of Packaging Sealing Machines

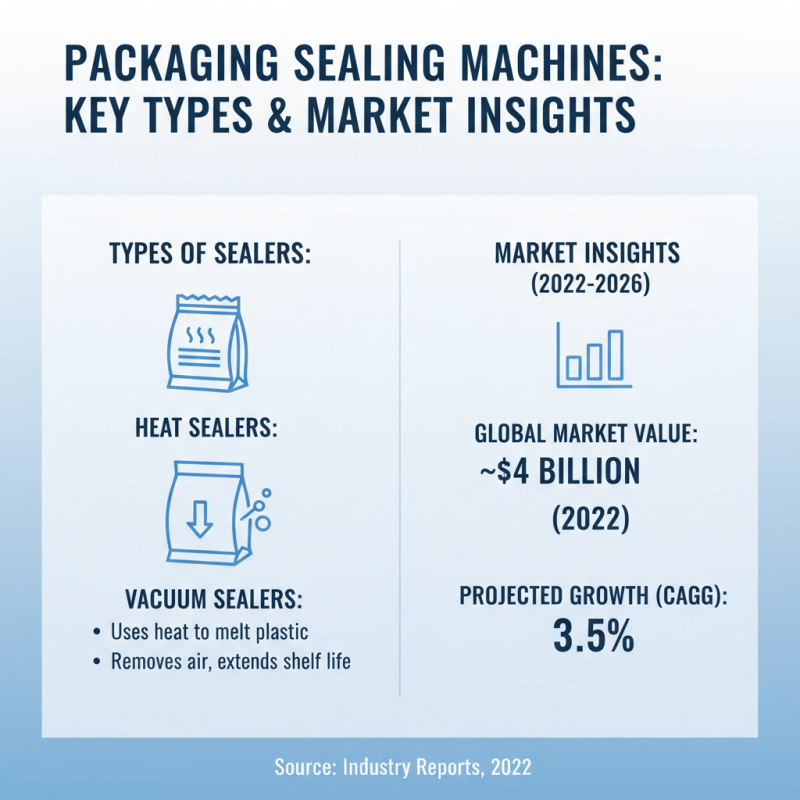

When considering the best packaging sealing machine, it's crucial to understand the various types available. From heat sealers to vacuum sealers, each machine serves a unique purpose. Heat sealers create a strong bond using heat to melt plastic. Vacuum sealers remove air, extending the shelf life of products. According to industry reports, the global packaging sealing machinery market was valued at approximately $4 billion in 2022 and is expected to grow at a CAGR of 3.5% by 2026.

Tips: Always assess your specific needs before investing. Evaluate the type of products you package. Assess the speed required to meet your production demands. This understanding can prevent costly mistakes.

Another critical factor is machine compatibility. Ensure the sealing machine works with your packaging materials. Different materials may require specialized seals for optimal integrity. Overlooking this can lead to product spoilage and customer dissatisfaction. The market reflects increasing innovation in sealing technology, addressing these diverse needs.

Tips: Try a trial run if possible. Testing can reveal unforeseen issues. Don't rush into a decision. Take your time to compare features and performance.

Key Factors to Consider When Choosing a Packaging Sealing Machine

Choosing the right packaging sealing machine is crucial for any business. There are several factors to consider. First, understand the materials you want to seal. Different machines work better with different materials. Some machines excel at sealing plastic, while others are better with paper or metal.

Next, consider the production speed. Does your business demand high output? If yes, you may need a faster machine. However, faster doesn't always mean better. A high-speed machine can lead to errors if not monitored closely. Operators should be well-trained to handle the equipment.

Another factor is the machine's size and space requirements. Will it fit in your workspace? Some machines are bulky. They require more room, which can be a problem in a small facility. Evaluate your workflow. A poorly placed machine can cause delays and inefficiencies. Don't overlook maintenance as well. Frequent breakdowns can affect productivity. Think through these aspects before making your decision.

2026 How to Choose the Best Packaging Sealing Machine for Your Business? - Key Factors to Consider When Choosing a Packaging Sealing Machine

| Factor | Description | Importance Rating (1-5) | Price Range (USD) |

|---|---|---|---|

| Speed | The number of packages sealed per hour. | 5 | $2,000 - $20,000 |

| Type of Material | Compatibility with various packaging materials (plastic, foil, paper). | 4 | $1,500 - $15,000 |

| Ease of Use | User-friendliness of the controls and setup. | 5 | $1,200 - $10,000 |

| Maintenance | Frequency and cost of maintenance required. | 3 | $500 - $3,000 |

| Portability | Ease of moving the machine as needed. | 4 | $800 - $7,000 |

| Energy Efficiency | Power consumption and efficiency ratings. | 3 | $1,000 - $5,000 |

Evaluating Production Capacity and Efficiency for Your Business Needs

When selecting a packaging sealing machine, understanding production capacity and efficiency is crucial. Studies have shown that up to 70% of operational efficiency is linked to the equipment used. A machine's capacity should align with your daily production goals. If you need to package 1,000 units each day, ensure your chosen machine can handle at least 1,200 units to accommodate fluctuations.

Efficiency also directly impacts costs. A report indicated that reducing sealing time by 15% can lead to a 10% decrease in overall production costs. This efficiency can boost your bottom line significantly. However, purchasing sleek, high-capacity machines may not always be the best route. They can require substantial maintenance and training.

**Tips:** Performance metrics matter. Always check the machine's operating speeds and downtime. Additionally, consider the adaptability of the machine. Can it handle various package types? A flexible solution may save you time and money.

Keep in mind, every business is unique. What works for one may not suit another. Assess your specific needs thoroughly before making a decision. This reflection will help avoid costly mistakes. Efficient packaging is not just about speed; it’s about fitting your specific situation perfectly.

Production Capacity and Efficiency of Sealing Machines

Assessing Cost vs. Quality in Packaging Sealing Machines

When considering packaging sealing machines, businesses face a crucial decision: cost versus quality. This dilemma is not easy. A lower-priced machine may save money initially but could lead to higher long-term expenses. Frequent breakdowns and inconsistent sealing can cause product spoilage. A business might experience a loss of customer trust due to poor packaging.

On the other hand, investing in a quality machine can seem daunting. The upfront cost is significant. However, durable and reliable machines often lead to reduced maintenance costs. They also provide consistency in sealing, which is vital for brand reputation. A good packaging sealing machine ensures that products are well-protected. This investment may pay off by reducing waste and improving customer satisfaction.

In the end, weigh the importance of your products and brand. The choice isn’t just about the sticker price. Consider the overall value that quality can bring. Take time to research and reflect. What may seem like a bargain today could cost more tomorrow. Finding the right balance between cost and quality is essential for long-term success.

Maintenance and Support Options for Long-term Use of Sealing Machines

When investing in a sealing machine, maintenance and support are crucial. Regular upkeep extends the life of your machinery. According to industry reports, businesses that maintain their equipment can reduce operational costs by 30%. This emphasizes the importance of a solid maintenance plan.

Training staff on proper usage is essential. Proper handling can prevent early breakdowns. A survey by the Packaging Machinery Manufacturers Institute noted that 40% of machinery issues stem from user error. Creating a training manual or routine can mitigate this risk. Regular check-ups should be a part of your monthly schedule.

Support options also vary widely. Many manufacturers offer contracts for regular service. These can provide peace of mind. Yet, companies often overlook these options. Ignoring support could result in unexpected downtime. Long-term, having consistent technical support enhances efficiency.

Related Posts

-

Common Issues Faced by Businesses Using Food Packaging Machine

-

5 Best Packaging Systems for Streamlining Your Business Operations

-

How to Choose the Best Plastic Tray Sealing Machine for Your Business

-

Top 10 Food Packaging Machines You Should Know in 2023

-

Why You Should Invest in an Automatic Packing Machine for Your Business Efficiency

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency