How to Choose the Right Blister Pack Packaging for Your Products?

Choosing the right blister pack packaging is essential for product integrity and consumer appeal. According to a recent industry report by Smithers Pira, the global blister packaging market is projected to reach $30 billion by 2025. This rapid growth underscores the importance of selecting appropriate packaging solutions. Deciding on the right blister pack can significantly impact shelf life, user experience, and brand perception.

Dr. Emily Morgan, a renowned expert in packaging technology, emphasizes, "Effective blister pack packaging protects products while enhancing customer interaction." This highlights the dual role of blister packs in safeguarding items and attracting consumers. However, many companies still overlook vital considerations. Attributes such as material compatibility and environmental impact often receive insufficient attention.

Brands face pressure to balance functionality with sustainability. Often, this leads to compromises in material choice or design efficiency. As the industry evolves, reflecting on these challenges fosters better decision-making. With the right knowledge, businesses can enhance their products and meet consumer demands.

Understanding the Purpose of Blister Pack Packaging

Blister pack packaging serves a vital role in product presentation and protection. It offers a clear view of the item inside. This transparency can boost consumer trust. Customers want to see what they are buying. When products are visible, it creates a sense of assurance. Additionally, blister packs can deter tampering. This helps ensure that customers receive safe, unaltered products.

Choosing the right blister pack is not just about aesthetics. It’s also about functionality. The material used can affect the product's shelf life. For instance, using high-barrier materials can prolong freshness. However, these options might be more costly. Finding a balance between cost and quality is often challenging. There could be unexpected compromises in durability and appearance.

Moreover, consider environmental impact. Sustainable options are becoming more desirable. Consumers increasingly prefer eco-friendly packaging. Yet, not all materials can meet protection needs. This presents a dilemma for manufacturers. They must weigh the desire for sustainability against product safety. Ultimately, understanding the purpose of blister packaging requires careful consideration and reflection.

How to Choose the Right Blister Pack Packaging for Your Products?

| Product Type | Blister Pack Material | Seal Type | Ventilation Needs | Child Resistance |

|---|---|---|---|---|

| Pharmaceuticals | PVC/Aluminum | Heat Seal | No | Yes |

| Consumer Electronics | PET | Cold Seal | Yes | No |

| Food Products | PVC/PE | Heat Seal | No | No |

| Toys | PET/Aluminum | Heat Seal | Yes | Yes |

| Cosmetics | PVC | Cold Seal | No | No |

Identifying the Types of Products Suitable for Blister Packs

When it comes to choosing packaging, blister packs stand out for various products. They appeal to many industries due to their unique benefits. A recent study revealed that the global blister packaging market is expected to reach $25 billion by 2026. This shows the growing demand for efficient and effective packaging solutions.

Blister packs work well for pharmaceuticals, consumer goods, and electronics. They protect products from moisture and physical damage. For instance, many over-the-counter medications use blister packs. This helps maintain the integrity of the pills until consumption. According to industry reports, around 70% of consumers prefer products with visible packaging because it reflects reliability.

However, not every product is ideal for blister packs. Fragile items may require additional cushioning. The design needs to accommodate the product's shape and size. Additionally, challenges in recycling packaging materials have raised questions among manufacturers. They need to address sustainability concerns while ensuring product safety. The choice of packaging should align with both product requirements and consumer expectations.

Evaluating Material Options for Blister Pack Durability and Safety

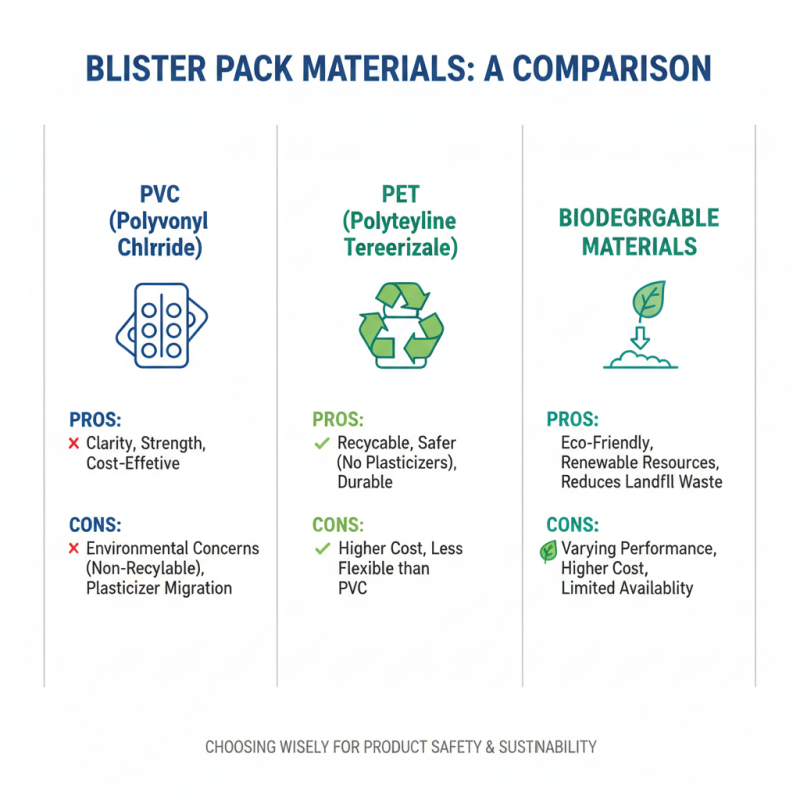

Choosing the right material for blister pack packaging is crucial for product safety and durability. The primary options include PVC, PET, and biodegradable materials. PVC is popular due to its clarity and strength. However, it raises concerns about environmental impact. PET offers a safer option, known for its recyclability, but can be more expensive.

When considering safety, the chosen materials must be compatible with the product inside. A chemical reaction between the packaging and the product can spoil the contents. Testing is key. Some materials may not provide the barrier needed to protect sensitive items. Mistakes in this area can lead to product failures.

Durability is another essential factor. Packaging must withstand shipping and handling without compromising the product. Thin materials may cut costs but could lead to damage. Customers often notice these flaws. Investing in better materials can prevent losses in customer trust. Each choice has its pros and cons, requiring careful consideration of product needs versus budget constraints.

Considering Design and Aesthetics in Blister Pack Selection

Choosing the right blister pack is critical for your product's success.

Design and aesthetics play significant roles in attracting customers. According to a recent industry report,

65% of consumers decide to purchase based on packaging design. This

highlights the importance of creating an eye-catching blister pack.

Consider color and material.

Bright colors may grab attention, while eco-friendly materials can enhance brand image. A stunning visual appeal

can set your product apart. However, focus should also be on functionality.

An attractive package that fails to protect the product is ineffective.

Tips:

- Use clear materials to showcase your product. Transparency can boost customer trust.

- Test different designs with focus groups. Feedback can provide valuable insights.

- Think about user experience. Easy-to-open packs are often preferred.

Balancing aesthetics with practicality is challenging. Packaging that looks great might not protect effectively.

Reflect on the perfect blend for your products. Remember, the right packaging

can elevate your brand.

Assessing Cost-Effectiveness and Production Factors in Blister Packaging

Choosing the right blister pack packaging isn’t just about looks. Cost-effectiveness plays a major role. While attractive packaging can draw attention, it’s essential to balance aesthetics with your budget. Often, companies overlook production costs. They may spend more on visuals than on function. This can lead to higher retail prices. Customers may not appreciate the extra expense.

Production factors should guide your decisions. Material choices affect both cost and quality. Some materials are cheaper but may not protect the product well. Your product's lifespan is at stake. Evaluate how the blister pack will be filled, sealed, and shipped. Each of these steps incurs costs. Are you using automation or manual labor? The method can significantly influence expenses. It’s worth considering how these factors impact overall profitability. A careful assessment can prevent costly mistakes down the line.

Cost-Effectiveness and Production Factors in Blister Packaging

This chart displays the cost-effectiveness and various production factors associated with different types of blister packaging. The data compares cost per unit and production time for three types of blister packs: Standard, Child-Resistant, and High-Barrier.

Related Posts

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

How to Choose the Right Blister Pack Packaging for Your Product Needs

-

Top 10 Tips for Effective Blister Packaging Design to Enhance Product Appeal

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

How to Optimize Blister Tray Packaging for Maximum Product Protection and Cost Efficiency