How to Choose the Right Tray Sealer Packaging Machine for Your Business?

Choosing the right tray sealer packaging machine for your business is crucial. The packaging process can make or break your product's appeal. A suitable machine ensures efficiency and quality. This equipment varies widely in features and capabilities. Some models are better for small-scale production, while others excel in high-volume environments.

Think about the materials you will use. Different tray sealers handle various types of films and trays. Not every machine fits every product type. You might find that a cheaper model does not meet your needs. Research is essential. Consider your production speed, budget, and product specifications.

When selecting a tray sealer packaging machine, don’t overlook after-sale support. A reliable supplier can make a significant difference. If something goes wrong, having a supportive partner is invaluable. Always evaluate and reflect on your choices. Investing in the right machine is not merely a financial decision; it shapes your brand's future.

Understanding the Different Types of Tray Sealer Packaging Machines

When selecting a tray sealer packaging machine, understanding the various types is crucial. There are semi-automatic and automatic machines available. Semi-automatic models require manual intervention, while automatic machines handle the entire process. According to a report by IBISWorld, about 47% of food packaging companies prefer automatic machines for efficiency and consistency. These machines can significantly speed up packaging lines.

Different materials may also dictate the choice of machine. Some tray sealers work well with plastic, while others handle aluminum or cardboard trays better. For instance, a recent study indicated that 62% of manufacturers noticed improved product freshness with specific materials. This emphasizes the need to match the machine capabilities with your packaging materials. It's vital to evaluate your production volume and the types of products you package.

Budget constraints frequently influence equipment selection. Many businesses may opt for less expensive models, but these can have limitations. For instance, they may not handle varying tray sizes efficiently. Consistent maintenance is another area that often gets overlooked. Neglecting this can lead to downtime, which directly affects productivity. Hence, it is essential to balance cost with performance and reliability.

Evaluating Your Production Needs and Volume Requirements

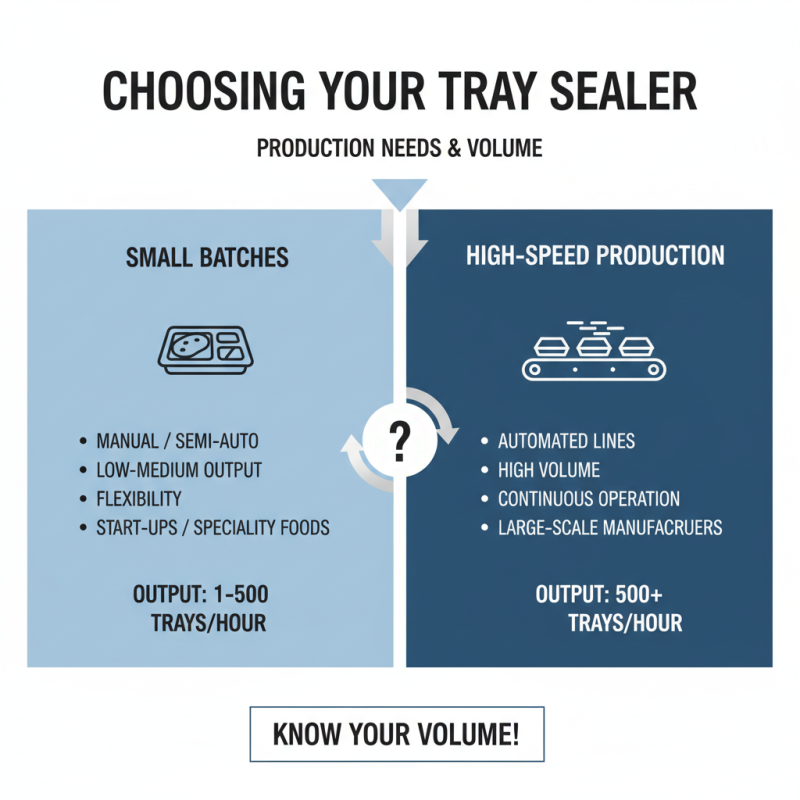

Choosing the right tray sealer requires careful evaluation of production needs and volume requirements. Understanding your output is crucial. Do you package small batches, or do you need high-speed production? Your answer will guide your decision.

When analyzing your production volume, consider fluctuation. Some businesses experience seasonal changes. This variability can affect machinery choice. A machine that handles 500 packs per hour may not suffice during peak seasons. Think about scalability. Can the machine accommodate future growth?

Tips: Always calculate the maximum volume you anticipate. This helps prevent future strain on the equipment. Investing in a versatile machine can save money in the long run. Don’t overlook maintenance costs; they can add up. Be realistic about your needs and your budget. A machine should serve you well, not become a burden. Reflect on your production workflow, too. Inefficiencies may not show immediately but can lead to bigger issues later.

Key Features to Look for in a Tray Sealer Packaging Machine

Choosing the right tray sealer packaging machine is crucial for your business. When evaluating options, focus on key features that can impact efficiency and product quality.

First, consider the sealing technology. A machine offering both heat sealing and vacuum sealing can provide flexibility. Heat sealing is essential for moisture-sensitive products, while vacuum sealing extends shelf life by reducing oxygen exposure. Research indicates that vacuum-sealed products can remain fresh up to 5 times longer compared to traditional packaging.

Next, look at the machine's speed and output capacity. For high-demand environments, select a machine that can handle a higher volume of trays per minute. Industry reports show that companies streamlining their packaging process by improving speed can increase productivity by approximately 30%.

Tip: Always assess the maintenance requirements. A machine that requires frequent repairs can lead to downtime and increased operational costs.

Also, consider the ease of use. A user-friendly interface ensures faster training for staff. This is critical, especially if you have high turnover. Investing in technology that is simple to operate can save time and reduce errors.

In the end, evaluate your unique needs. What works for one business may not fit another. Take time to assess and choose wisely.

Assessing Budget and Cost-Effectiveness of Tray Sealers

When assessing budget and cost-effectiveness of tray sealers, it’s crucial to consider several factors. Many businesses choose machines based on price alone, which can lead to unsatisfactory outcomes. A low-cost machine may save money initially but could incur high maintenance costs later.

Invest in a reliable model that meets your production needs. Sometimes, higher upfront costs translate into savings over time. This is often due to enhanced efficiency and durability. It’s wise to conduct a cost-benefit analysis before deciding. Think about production volume and speed. Will the machine handle future growth?

**Tip:** Always review warranties and service agreements. Some companies offer extensive support, while others leave you on your own.

Remember, cheap isn’t always better. Look beyond the sticker price. Quality impacts performance and longevity. If possible, get user feedback or test machines before purchasing.

**Tip:** Don’t overlook energy efficiency. Machines that consume less energy might cost more upfront but save you money long-term.

Understand the total cost of ownership. Analyze what you’ll spend in maintenance, supplies, and downtime. This larger perspective can help you invest wisely. Balancing cost and quality is key to finding the right tray sealer for your business.

How to Choose the Right Tray Sealer Packaging Machine for Your Business? - Assessing Budget and Cost-Effectiveness of Tray Sealers

| Feature | Value 1 | Value 2 | Value 3 |

|---|---|---|---|

| Machine Type | Semi-Automatic | Automatic | Fully Automatic |

| Average Cost | $15,000 | $30,000 | $50,000 |

| Production Speed (trays/hour) | 300 | 600 | 1200 |

| Power Consumption (kWh) | 2 | 5 | 10 |

| Maintenance Frequency | Monthly | Quarterly | Bi-Annually |

| Material Compatibility | Plastic | Plastic, Aluminum | Plastic, Aluminum, Cardboard |

Maintenance and Support Considerations for Tray Sealer Machines

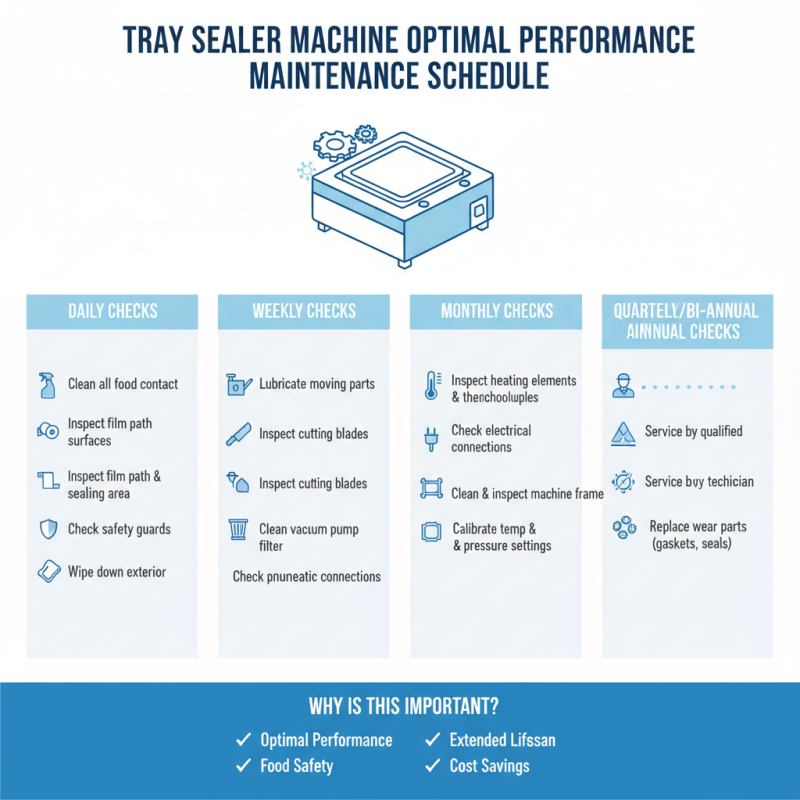

Maintaining your tray sealer machine is essential for optimal performance. Regular maintenance ensures longevity and efficiency. Create a schedule for routine check-ups. This could include daily, weekly, or monthly tasks depending on usage. Pay attention to cleaning and lubrication. Neglecting these aspects can lead to premature breakdowns.

Tip: Keep a maintenance log. Document every service and repair. This will help identify patterns or recurring issues. It can also assist when seeking support from technicians. Don’t overlook the importance of cleanliness. A dirty machine can affect your product quality.

Consider support options carefully. Whether it's in-person service or remote troubleshooting, having reliable support is crucial. Evaluate the availability of technical assistance. Check if the machine comes with a warranty. Understand what it covers and for how long. Knowing your support avenues can save time and money in the long run.

Tip: Train your staff on basic troubleshooting. Sometimes, simple issues may arise that they can handle. This can reduce downtime and increase efficiency. Preventative training is an investment worth considering.

Related Posts

-

How to Choose the Right Tray Sealer Packaging Machine for Your Business?

-

Revolutionizing Food Preservation: The Role of Tray Sealer Packaging Machines in Modern Manufacturing

-

How to Optimize Your Production Line with a Tray Sealer Packaging Machine

-

Understanding the Benefits of Tray Sealer Packaging Machines for Food Safety and Freshness

-

Top 10 Benefits of Using Tray Sealer Packaging Machine?

-

Common Issues Faced by Businesses Using Food Packaging Machine