How to Choose the Right Blister Pack Packaging for Your Product Needs

Blister pack packaging has become an increasingly vital component in a variety of industries, including pharmaceuticals, consumer goods, and electronics. As reported by the Global Blister Packaging Market Analysis, the market is projected to reach approximately $29 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This surge is driven by the rising demand for enhanced product protection, user convenience, and the need for tamper-proof solutions. Choosing the right blister pack packaging can significantly influence product safety, shelf life, and consumer satisfaction.

Factors such as material selection, design, and functionality are crucial when determining the most suitable blister pack for a product. According to industry insights, over 50% of consumers prefer packaging that provides easy usability and clear product visibility. Furthermore, sustainable packaging is becoming a priority, with 73% of consumers expressing a preference for eco-friendly materials. As companies navigate these evolving trends, understanding the intricacies of blister pack packaging—such as its production costs, aesthetic appeal, and compliance with regulatory standards—becomes essential for meeting market demands and optimizing brand perception.

Understanding the Basics of Blister Pack Packaging

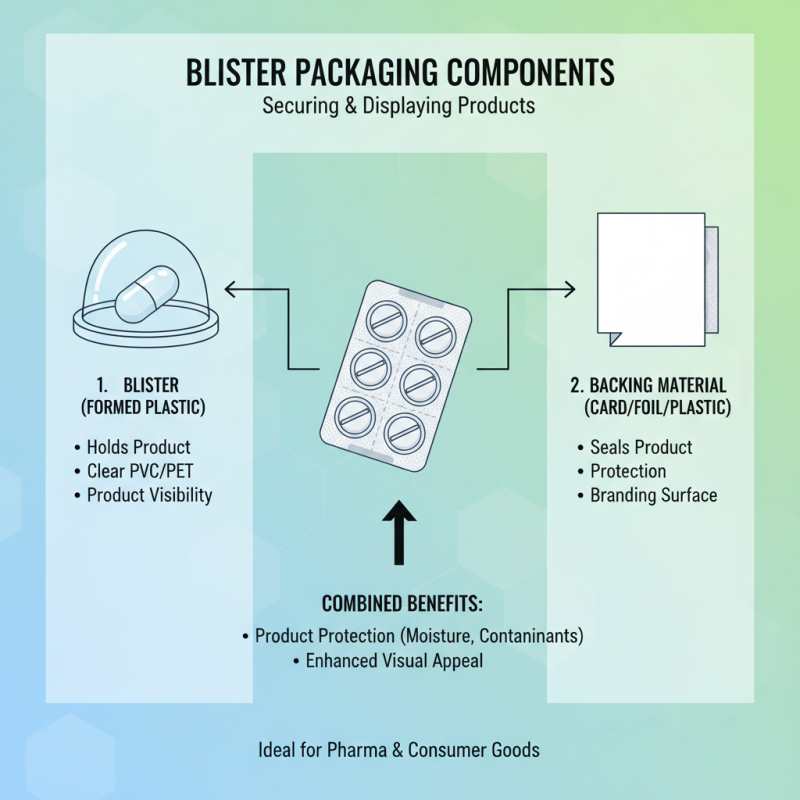

Blister pack packaging is a widely utilized method for securing and displaying products, particularly in the pharmaceutical and consumer goods industries. Understanding the basic components of blister packaging can help businesses make informed decisions when selecting the right solution for their products. At its core, blister packaging consists of two main parts: the blister, which holds the product, and the backing material, typically made of cardboard or plastic. This combination not only protects the product from environmental factors but also provides a visual appeal that can enhance consumer interest.

When considering blister pack packaging, it’s essential to evaluate the compatibility of materials with the intended product. Factors such as moisture resistance, barrier properties, and durability play a critical role in ensuring product integrity. Additionally, businesses should consider the ease of opening for consumers, as well as any regulatory requirements specific to the product type. Choosing the right design can also influence production costs and efficiency, making it imperative to strike a balance between functionality and aesthetics to meet diverse market needs effectively.

Identifying the Specific Requirements of Your Product

When selecting blister pack packaging, it's crucial to first identify the specific requirements of your product. Understanding the physical and chemical properties of your item will guide your packaging choice. For example, consider factors such as product size, shape, and weight, as well as its sensitivity to moisture, light, and temperature. This initial assessment ensures that the blister pack not only accommodates the product comfortably but also protects it against external elements that could compromise its integrity.

Next, take into account the intended use and target market of your product. This includes considering how consumers will interact with the packaging—whether they need easy access to the product or if child-resistant features are necessary. Additionally, think about the shelf life of your product. Certain materials may be more suitable for extending freshness or preventing contamination. Balancing these specifics with branding and consumer preferences will help create a packaging solution that is both functional and appealing, ultimately enhancing the overall user experience.

How to Choose the Right Blister Pack Packaging for Your Product Needs - Identifying the Specific Requirements of Your Product

| Product Type | Material | Size (mm) | Thickness (mm) | Transparency | Child Resistance | Shelf Life |

|---|---|---|---|---|---|---|

| Pharmaceutical Tablets | PVC/PE | 60 x 90 | 0.5 | High | Yes | 2 Years |

| Nutritional Supplements | PET | 50 x 70 | 0.4 | Moderate | No | 1 Year |

| Cosmetics | Aluminum/Plastic | 40 x 60 | 0.3 | High | No | 2 Years |

| Electronics Components | PVC | 30 x 50 | 0.2 | Low | No | Indefinite |

| Toys | PET | 70 x 90 | 0.5 | Moderate | Yes | 3 Years |

Evaluating Material Options for Blister Packaging

When evaluating material options for blister packaging, it’s crucial to consider the specific needs and characteristics of your product. The most common materials used for blister packs include PVC, PET, and aluminum. PVC is known for its versatility and cost-effectiveness, making it an ideal choice for a wide range of applications. It offers excellent clarity and allow for effective product visibility, which is essential in attracting consumers' attention. However, its environmental impact is a growing concern, as PVC can be less recyclable compared to other options.

On the other hand, PET is gaining popularity due to its superior barrier properties and recyclability. This material helps protect products from moisture and oxygen, thus extending their shelf life. Additionally, PET is more environmentally friendly than PVC, which aligns with a growing commitment to sustainability among consumers and manufacturers alike. Aluminum, while more expensive, provides complete protection from light and oxygen, making it the best choice for sensitive items. Each material has its unique benefits and drawbacks, and selecting the right one will depend on factors such as product sensitivity, shelf life requirements, and environmental considerations.

Considering Design and Functionality in Packaging

When selecting blister pack packaging, design and functionality are key considerations that can significantly impact product protection, consumer appeal, and overall usability. According to a report by Smithers Pira, the global blister packaging market is projected to reach $24 billion by 2025, driven by the increasing demand for convenient and visually appealing packaging solutions. This data highlights the essential role that effective design plays in attracting consumers, as well as the necessity for packaging that aligns with product specifications.

Functionality goes beyond just aesthetics; it includes how the packaging interacts with the product and the end-user. Blister packs are engineered to shield items from environmental factors such as moisture and light while also allowing for easy access. Research from Freedonia Group indicates that around 22% of specialty packaging sales are attributed to the growing use of advanced materials that enhance barrier properties and prevent contamination. Without effective functionality, even the most visually striking packaging can fall short in maintaining product integrity and user satisfaction.

When choosing blister pack packaging, businesses must strike the right balance between eye-catching design and practical functionality. By focusing on these aspects, companies can ensure their products not only stand out on the shelves but also meet the rigorous demands of transportation and storage, ultimately leading to an enhanced consumer experience and greater brand loyalty.

Assessing Cost-Effectiveness and Production Efficiency

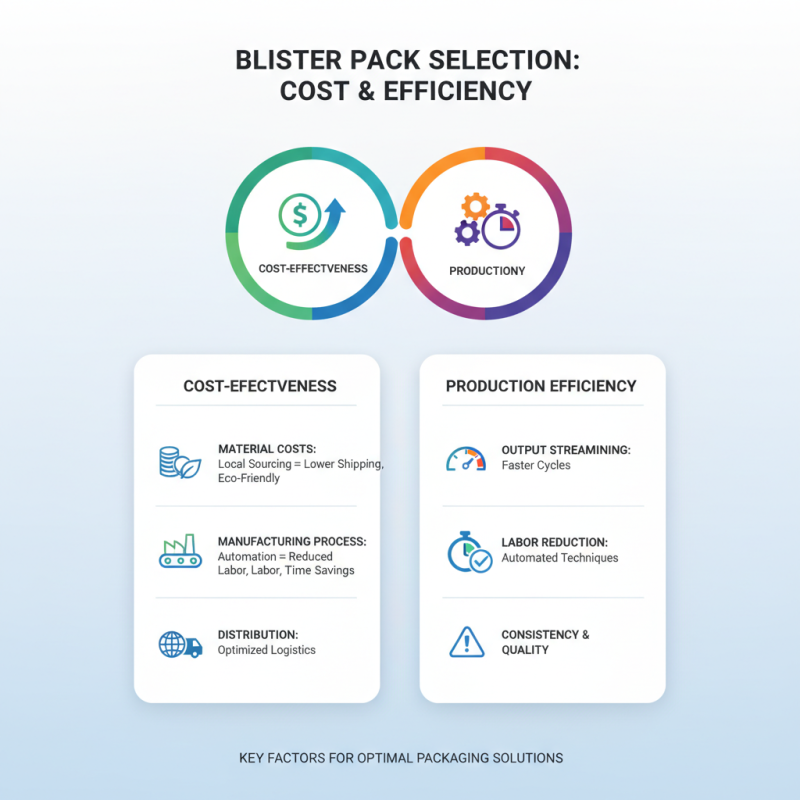

When selecting blister pack packaging, it is crucial to conduct a thorough assessment of its cost-effectiveness and production efficiency. First, calculating the overall costs involved in the sourcing, production, and distribution of the chosen blister pack design is essential. Factors including material costs, manufacturing processes, and labor should be taken into consideration. For instance, opting for materials that can be sourced locally may reduce shipping expenses and contribute to lower environmental impact, while automated production techniques can streamline output, reducing labor costs and time.

In addition to costs, evaluating production efficiency is vital for optimizing the packaging process. This includes reviewing the time required for setup, production runs, and quality control checks. Opting for designs that minimize waste—both in materials and time—can significantly enhance efficiency. Furthermore, implementing a just-in-time (JIT) production system can help meet demand without overproducing, thus saving valuable resources. By balancing these aspects, businesses can ensure they choose a blister pack that not only meets their product requirements but is also economically viable and efficient in terms of production capabilities.

Related Posts

-

How to Optimize Blister Tray Packaging for Maximum Product Protection and Cost Efficiency

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

Unlocking Efficiency: The Future of Blister Packaging Equipment in Modern Manufacturing

-

Best Heat Sealing Machine for Blister Packaging 2023 Top Choices for Your Packaging Needs