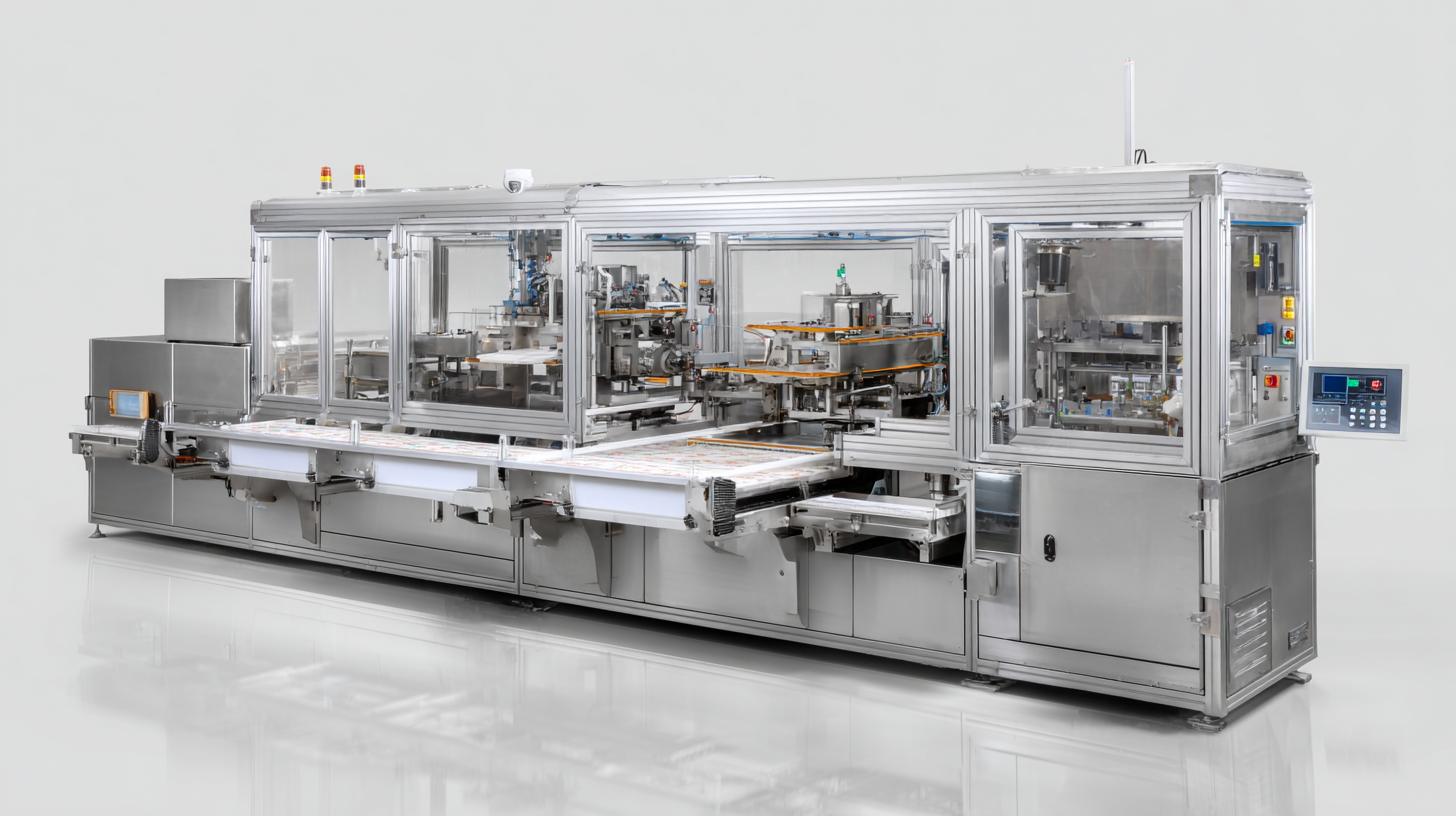

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency

In the competitive landscape of food packaging, optimizing the performance of a tray sealer packaging machine is crucial to enhancing operational efficiency and product quality. According to a recent industry report by Smithers, the global food packaging market is projected to reach a value of $500 billion by 2025, with a significant demand for innovative packaging solutions that ensure food safety and shelf life. As manufacturers strive for higher output and reduced waste, focusing on the efficiency of tray sealer packaging machines has never been more important.

Implementing strategic enhancements not only helps in minimizing downtime and material costs but also improves the overall productivity of packaging lines. In this blog, we will explore seven essential tips that can help you unlock the full potential of your tray sealer packaging machine, ensuring that your operations stay competitive and cost-effective in today’s fast-paced market.

Maximizing Tray Sealer Efficiency: Understanding Throughput Rates and Machine Speeds

Maximizing the efficiency of your tray sealer packaging machine is crucial for meeting production targets while maintaining quality. Understanding throughput rates—the number of trays sealed per hour—is essential for evaluating machine performance. By analyzing these rates, you can identify bottlenecks in your packaging line and make informed decisions to enhance productivity. For instance, if your current throughput does not meet your output goals, it might be time to reassess the speed settings or check if any mechanical issues are holding back performance.

Machine speed also plays a pivotal role in overall efficiency. Adjusting the sealing speed to align with your production demands can significantly reduce waste and downtime. High-speed operation is beneficial, but it’s important to find the right balance; excessively fast speeds can lead to higher error rates or compromised seals. Implementing advanced monitoring technologies can provide real-time data on machine performance, enabling you to fine-tune speeds and throughput rates in response to varying production requirements. Emphasizing these factors ensures that your tray sealing process aligns with operational objectives and enhances overall profitability.

Key Maintenance Practices to Extend the Lifespan of Your Tray Sealer

Maintaining your tray sealer is crucial for ensuring operational efficiency and longevity. One of the key practices to extend the lifespan of your packaging machine is regularly inspecting and cleaning all components. This includes checking the sealing plates and guides for any debris or wear that could affect their performance. A clean machine not only optimizes the sealing process but also reduces the risk of contamination in your products. Implementing a systematic cleaning schedule can prevent costly downtime and enhance overall productivity.

Another important maintenance practice is to monitor the machine's settings and make necessary adjustments. Keeping an eye on temperature, pressure, and timing settings ensures consistent sealing quality. If these parameters are off, it could lead to improper seals, resulting in product spoilage and increased waste. Additionally, routine lubrication of moving parts will minimize friction and wear, enhancing the machine's operational life. By prioritizing these maintenance tasks, you can significantly improve the efficiency of your tray sealer and protect your investment for years to come.

Importance of Proper Film Selection for Enhanced Packaging Performance

When it comes to optimizing the efficiency of your tray sealer packaging machine, the selection of the right film plays a pivotal role in enhancing overall packaging performance. Proper film selection not only ensures that the product remains fresh and secure but also significantly impacts the sealing quality and speed of the machine. The chosen film must be compatible with the products being packaged, considering factors such as temperature resistance, barrier properties, and ease of sealing. For instance, using a film that can withstand higher temperatures is crucial for refrigerated or cooked food items, as it helps maintain food safety and extends shelf life.

Additionally, the thickness and elasticity of the film affect the sealing process. A film that is too thick may not seal properly, leading to waste and increased production costs, while a film that is too thin may not provide adequate protection. It’s essential to conduct tests to determine the optimal film type that matches the packaging machine’s specifications and the items being sealed. By prioritizing proper film selection, businesses can not only enhance their packaging performance but also improve operational efficiency and reduce the risk of product loss due to inadequate sealing.

Leveraging Automation to Reduce Downtime in Tray Sealing Operations

Leveraging automation in tray sealing operations can significantly reduce downtime and enhance efficiency. One effective strategy is to implement predictive maintenance for your tray sealer packaging machine. By utilizing sensors and IoT technology, you can monitor the machine's performance in real-time, allowing for timely interventions before any potential failure occurs. This proactive approach ensures that your production line remains operational with minimal interruptions.

Another essential tip is to invest in automated loading and unloading systems. These systems streamline the process of placing trays into the machine and removing finished products, significantly reducing the manual labor involved. By minimizing human intervention, you not only cut down on the time taken for each cycle but also decrease the likelihood of errors that could lead to costly downtime.

Finally, consider integrating machine learning algorithms into your operations. These algorithms can analyze production patterns and adjust machine settings automatically for optimal performance. By continuously learning from the production data, the tray sealing machine can adapt to changing conditions, ensuring peak efficiency and further reducing downtime in your operations.

Implementing Process Monitoring for Real-time Efficiency Improvements in Tray Sealers

Implementing process monitoring in tray sealer packaging machines is crucial for achieving real-time efficiency improvements. According to a recent report by Smithers Pira, integrating smart technologies can lead to a 30% increase in operational efficiency. By continuously tracking key performance indicators such as cycle time, seal integrity, and material usage, manufacturers can identify bottlenecks and areas for enhancement immediately, significantly reducing downtime.

Moreover, real-time data analytics allows for predictive maintenance, which can further minimize machine failures. A study published by McKinsey indicates that companies utilizing advanced analytics and machine learning can reduce unplanned downtime by up to 25%. This proactive approach not only ensures that tray sealers operate at peak efficiency but also extends equipment lifespan, leading to lower costs and improved ROI. Investing in such monitoring technologies is no longer optional; it's a strategic necessity for those looking to compete in the fast-paced food packaging industry.

Real-time Efficiency Improvements in Tray Sealers

Related Posts

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business

-

Unlocking the Future of Packaging Automation with Digital Innovations

-

Innovative Examples of Packaging Equipment Transforming Global Supply Chains

-

7 Compelling Reasons to Choose Tray Packaging for Your Business Success

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

5 Best Packaging Systems for Streamlining Your Business Operations