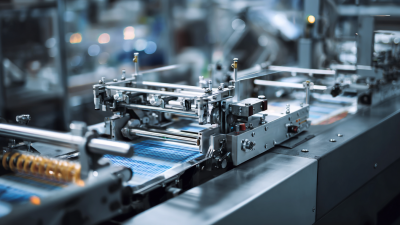

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

In today's packaging industry, the efficiency and reliability of production processes are paramount, and the choice of equipment plays a crucial role in achieving these goals. As per a recent report by Smithers Pira, the global blister packaging market is projected to reach $37 billion by 2024, reflecting a compound annual growth rate of 5.8%. Within this expansive market, the blister heat sealing machine stands out as an essential tool for ensuring optimal sealing quality and product protection.

However, selecting the right blister heat sealing machine can be a daunting task, given the myriad of options available, each designed for specific applications and materials. This guide aims to demystify the decision-making process by providing essential tips and insights to help businesses identify the right machine tailored to their unique packaging needs, ultimately enhancing production efficiency and product safety.

Key Factors to Consider When Selecting a Blister Heat Sealing Machine

When selecting a blister heat sealing machine for your packaging needs, several key factors should be taken into account to ensure optimal performance and efficiency. First and foremost, the material compatibility is critical. According to a report by Grand View Research, the global blister packaging market is projected to reach $30.7 billion by 2025, emphasizing the importance of selecting a machine that can handle diverse materials such as PVC, PET, and aluminum to accommodate various products. The chosen machine should be versatile enough to seal different blisters and accommodate diverse product shapes and sizes.

Another crucial factor is the machine's sealing technology. Different technologies, such as impulse sealing, continuous sealing, and radio frequency sealing, can greatly affect the heat seal quality and production speed. Data from MarketsandMarkets indicates that the efficiency of heat sealing can impact overall productivity by as much as 25%. Therefore, investing in a machine that utilizes the latest sealing technology ensures reliable seals and minimizes the risk of product damage during packaging. Additionally, considering the machine's ease of operation and maintenance can significantly influence long-term operational costs, highlighting the importance of making informed decisions based on industry standards and technological advancements.

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs - Key Factors to Consider When Selecting a Blister Heat Sealing Machine

| Feature | Description | Importance Rating (1-5) |

|---|---|---|

| Machine Type | Consider whether you need a manual, semi-automatic, or fully automatic machine. | 5 |

| Production Speed | Evaluate the number of units produced per hour according to your output needs. | 4 |

| Heat Source | Select between electric, steam, or infrared heat sources based on efficiency and cost. | 3 |

| Material Compatibility | Ensure the machine can handle various materials such as PVC, PET, or paper. | 5 |

| User-Friendly Controls | Look for intuitive controls that simplify operation and reduce training time. | 4 |

| Safety Features | Choose machines with emergency shutoff, guards, and safety interlocks. | 5 |

| Maintenance Requirements | Consider how often you will need to service the machine and the associated costs. | 3 |

Understanding Different Types of Blister Heat Sealing Machines

When choosing the right blister heat sealing machine, understanding the different types available is crucial for meeting specific packaging needs. Blister heat sealing machines typically fall into two main categories: manual and automatic. Manual machines are often cost-effective and suitable for small-scale operations, where flexibility and ease of use are paramount. They allow operators to have direct control over the sealing process, making them ideal for environments with frequent changes in packaging designs.

On the other hand, automatic blister heat sealing machines are designed for larger production volumes and provide higher efficiency. These machines can cater to more complex packaging requirements, boasting features like precise temperature control and advanced sealing technologies. They are often employed in industries such as pharmaceuticals, food, and consumer goods, where speed and consistent quality are essential. Understanding the functional differences and production capabilities of these machines will help businesses select the right model that aligns with their operational goals and packaging demands.

Heat Sealing Machines Performance Comparison

Evaluating Production Volume and Speed Requirements for Your Packaging

When selecting the right blister heat sealing machine for your packaging needs, evaluating your production volume and speed requirements is crucial. The speed of the machine directly impacts your overall output and efficiency. If you operate in a high-demand environment, a machine that offers rapid sealing cycles will be essential to meet production targets without compromising quality. It's important to assess your daily production goals to determine whether a high-speed model or a more standard option aligns best with your operations.

Additionally, consider the volume of product you plan to package. A machine designed for high production runs may include features such as adjustable sealing temperatures and customizable mold configurations, allowing for flexibility in product types. Conversely, if your packaging needs fluctuate or your product variety is vast, opting for a machine with quick changeover capabilities would be beneficial. By thoroughly evaluating these parameters, you can select a blister heat sealing machine that not only meets your current requirements but also adapts to future demands, ensuring long-term efficiency and effectiveness.

Assessing Material Compatibility for Optimal Heat Sealing Performance

When selecting a blister heat sealing machine, assessing material compatibility is crucial for achieving optimal sealing performance. Different materials, such as PVC, PET, and aluminium, exhibit unique thermal properties that influence the sealing process. According to a report by Smithers Pira, the global blister packaging market is projected to reach $9.8 billion by 2025, highlighting the increasing demand for efficient packaging solutions. Understanding the thermal characteristics of your chosen materials will ensure a tight seal, reducing the likelihood of product loss and enhancing shelf life.

Tips: Before making a purchase, perform thorough compatibility tests with your specific materials. Utilize temperature profiling equipment to identify the ideal sealing temperatures for each material combination. Additionally, consider investing in a machine that offers adjustable temperature settings for flexibility across different products.

Moreover, it's vital to factor in the thickness and type of lidding material, as these can significantly affect sealing strength. According to a recent industry survey, over 40% of packaging failures are attributed to improper heat sealing parameters. By selecting a machine that can accommodate a range of material thicknesses and configurations, you can improve production efficiency and reduce waste.

Tips: Regular maintenance and calibration of the heat sealing machine can further enhance performance and prolong its lifespan, ensuring consistent output quality in a competitive market.

Cost Considerations and Budgeting for Your Blister Sealing Solution

When selecting a blister heat sealing machine, one of the foremost considerations is your budget. Understanding the initial investment and ongoing costs associated with the equipment is critical for making an informed decision. Be sure to research different manufacturers and models to compare prices. Consider not only the purchase price but also the potential costs for maintenance, parts replacement, and operation.

Tip: Create a detailed budget plan that outlines all potential expenses, including training for your staff on how to use the machine effectively. This will help you avoid surprises down the line and ensure that you can allocate resources wisely.

Moreover, it may be beneficial to evaluate the total cost of ownership over time. While a higher upfront cost might seem daunting, investing in a reliable machine with lower maintenance costs could save you money in the long run. Look for machines that offer warranties and support to mitigate future repairs and downtime.

Tip: Engage with other businesses in your industry to gain insights into their experiences with different machines. Their feedback can be invaluable in shaping your decision, potentially steering you toward more cost-effective solutions.

Related Posts

-

Common Issues Faced by Businesses Using Food Packaging Machine

-

7 Compelling Reasons to Choose Tray Packaging for Your Business Success

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

7 Essential Tips for Choosing the Right Food Packaging Machine for Your Business

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency