Innovative Heat Sealing Machine for Blister Packaging Revolutionizes Industry Trends at 2025 China Import and Export Fair

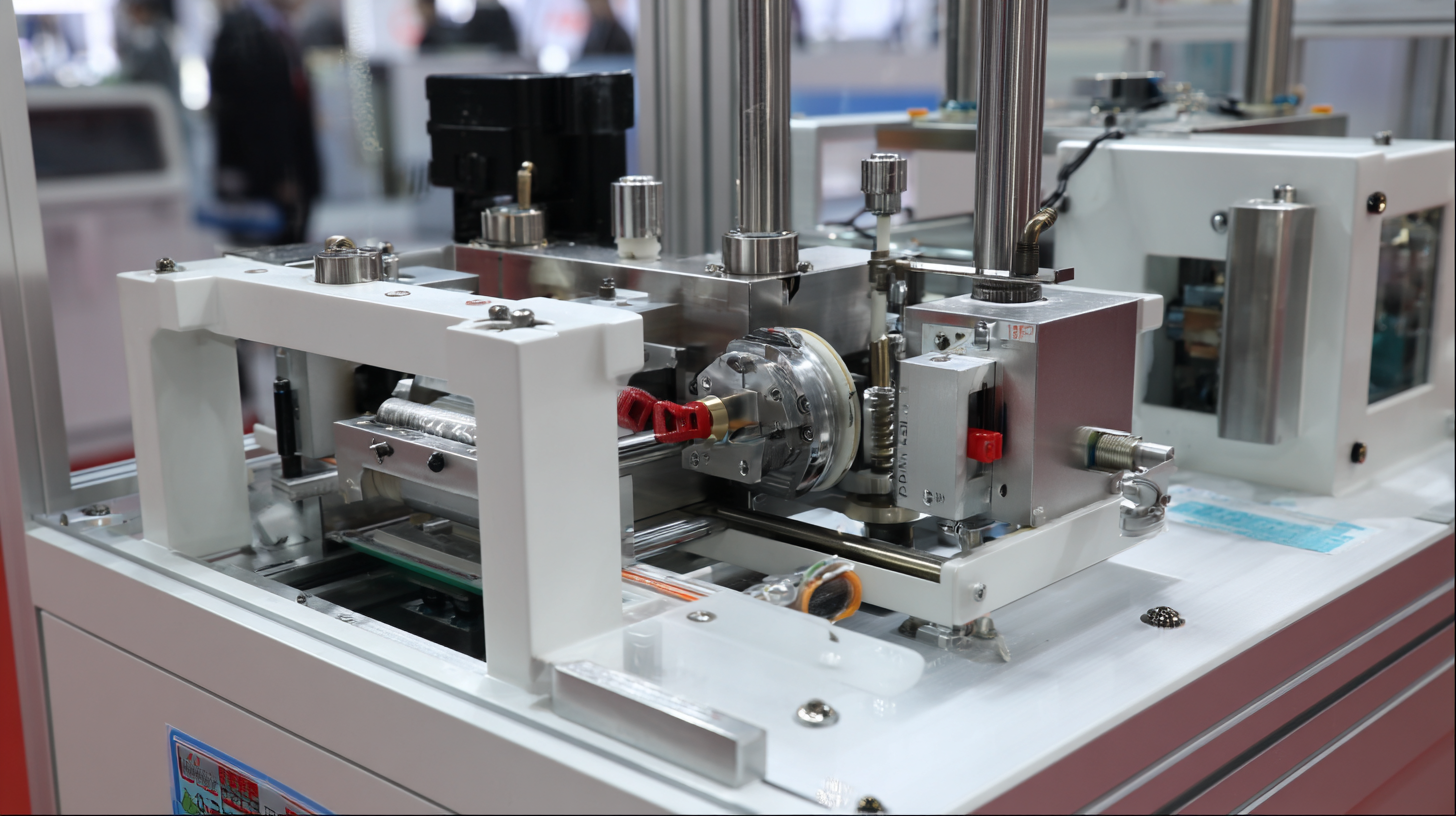

The unveiling of the innovative heat sealing machine for blister packaging at the 2025 China Import and Export Fair marks a significant turning point in the packaging industry. As companies increasingly seek efficient and sustainable ways to meet consumer demands, this cutting-edge technology showcases advancements that are set to revolutionize production processes. The heat sealing machine for blister packaging not only enhances product protection and quality but also streamlines the packaging workflow, reducing waste and operational costs.

With manufacturers and distributors eager to adopt the latest solutions presented at this prestigious fair, the impact of this innovation extends beyond individual businesses, influencing industry trends and setting new standards for performance and reliability in packaging technology. As the world focuses on upgrading its manufacturing capabilities, the significance of such advancements cannot be overstated, positioning the heat sealing machine as a cornerstone of future packaging endeavors.

Innovative Features of the Heat Sealing Machine Highlighted at the 2025 Fair

At the 2025 China Import and Export Fair, the unveiling of an innovative heat sealing machine for blister packaging has captured significant attention within the industry. This state-of-the-art machine incorporates advanced features such as enhanced temperature control, modular design, and user-friendly interfaces that cater specifically to the growing demands of the packaging sector. According to a recent report from Smithers Pira, the global blister packaging market is projected to reach $28 billion by 2027, highlighting the urgent need for efficient and reliable sealing technologies.

One of the standout features of this new heat sealing machine is its ability to adapt to various materials, ensuring consistent performance across different types of packaging. This flexibility is crucial, given the industry's shift towards sustainable materials, as evidenced by a study from Mordor Intelligence indicating that the eco-friendly packaging segment is expected to grow at a CAGR of over 5% through 2026. Additionally, the machine boasts a significant reduction in energy consumption, aligning with the industry's sustainability goals while simultaneously reducing operational costs for manufacturers. As packaging companies strive for greater efficiency and lower environmental impact, this innovative heat sealing machine is poised to set new benchmarks in the blister packaging sector.

Innovative Heat Sealing Machine for Blister Packaging

| Feature | Description | Impact on Industry | Sustainability Benefits |

|---|---|---|---|

| Automated Temperature Control | Ensures consistent sealing quality for various blister packages. | Improves product integrity and shelf life. | Reduces energy consumption during production. |

| User-Friendly Interface | Touchscreen controls for ease of operation. | Enhances efficiency and reduces training time. | Promotes reduced waste through precise use of materials. |

| Advanced Leak Testing | Integrated testing to identify leaks before packaging. | Minimizes product loss and maximizes delivery quality. | Supports sustainable practices by reducing recalls. |

| Multi-Material Compatibility | Works with various blister and plastic materials. | Increases flexibility in packaging options. | Encourages recycling by using eco-friendly materials. |

| Compact Design | Space-saving structure suitable for tight production areas. | Maximizes floor space utilization for manufacturers. | Lowers the carbon footprint due to efficient space use. |

Impact of Advanced Technology on Blister Packaging Efficiency

The introduction of the innovative heat sealing machine at the 2025 China Import and Export Fair has markedly enhanced the efficiency of blister packaging. With advanced technology integrated into its design, this machine significantly reduces production time while maintaining high-quality packaging standards. By streamlining the sealing process, manufacturers can achieve better product integrity and minimize wastage, essential factors that contribute to both economic savings and environmental sustainability.

Furthermore, the impact of this advanced technology is evident in the ability to cater to various products with different dimensions and materials. The machine's versatility allows for quick adjustments, enabling businesses to meet market demands swiftly. As a result, the blister packaging industry is experiencing a seismic shift towards more automated and efficient processes. This innovation not only meets the growing consumer expectations for quality and speed but also empowers companies to remain competitive in a rapidly evolving market landscape.

Market Trends Shaping the Future of Blister Packaging Industry

The blister packaging industry is currently witnessing transformative changes, driven by innovations in packaging technologies and materials. As highlighted in recent market analyses, the demand for sterile medical packaging is on the rise, propelled by increasing healthcare standards and the necessity for product safety. This evolution is reshaping market dynamics, with a particular emphasis on the materials used, which include plastics, glass, and paperboard. Innovations in these materials are leading to enhanced product durability and efficiency, which are crucial for preserving quality and extending shelf life.

Furthermore, the food packaging sector is experiencing a similar trend, where innovation is becoming a key driver for market growth. The development of advanced packaging solutions not only ensures food safety but also maintains product integrity throughout its lifecycle. As consumers become more health-conscious, the emphasis on sustainable and high-quality packaging is expected to intensify. This growing awareness presents significant opportunities for companies to differentiate their offerings, catering to market demands while adhering to global sustainability goals. The trajectory of packaging innovation is poised to play a pivotal role in shaping the future landscape of both the blister and food packaging industries.

Sustainability Initiatives in Heat Sealing Machine Development

The recent introduction of an innovative heat sealing machine for blister packaging at the 2025 China Import and Export Fair marks a significant step toward sustainability in the packaging industry. With the growing emphasis on eco-friendly practices, manufacturers are increasingly seeking solutions that minimize environmental impact. The new machine boasts a 30% reduction in energy consumption compared to traditional models and utilizes recyclable materials in its construction, aligning with global sustainability goals. A recent report from the Packaging Machinery Manufacturers Institute (PMMI) highlights that over 60% of industry leaders prioritize sustainability initiatives in their operations, further emphasizing the relevance of this technology.

Tips: When considering heat sealing solutions for your packaging needs, assess the machine's energy efficiency and materials used. This not only contributes to environmental conservation but can also lead to long-term cost savings.

Additionally, advancements in technology have made it possible to integrate smart features into heat sealing machines. These innovations allow for improved monitoring and control, ensuring more efficient production processes that also adhere to sustainability standards. Industry data reveals that businesses utilizing smart machinery experience a 25% increase in productivity while reducing waste. As the market evolves, embracing such technological advancements will be crucial for companies aiming to stay competitive while committing to sustainable practices.

Innovative Heat Sealing Machine for Blister Packaging: Industry Sustainability Trends

Key Players and Their Contributions to Industry Innovation

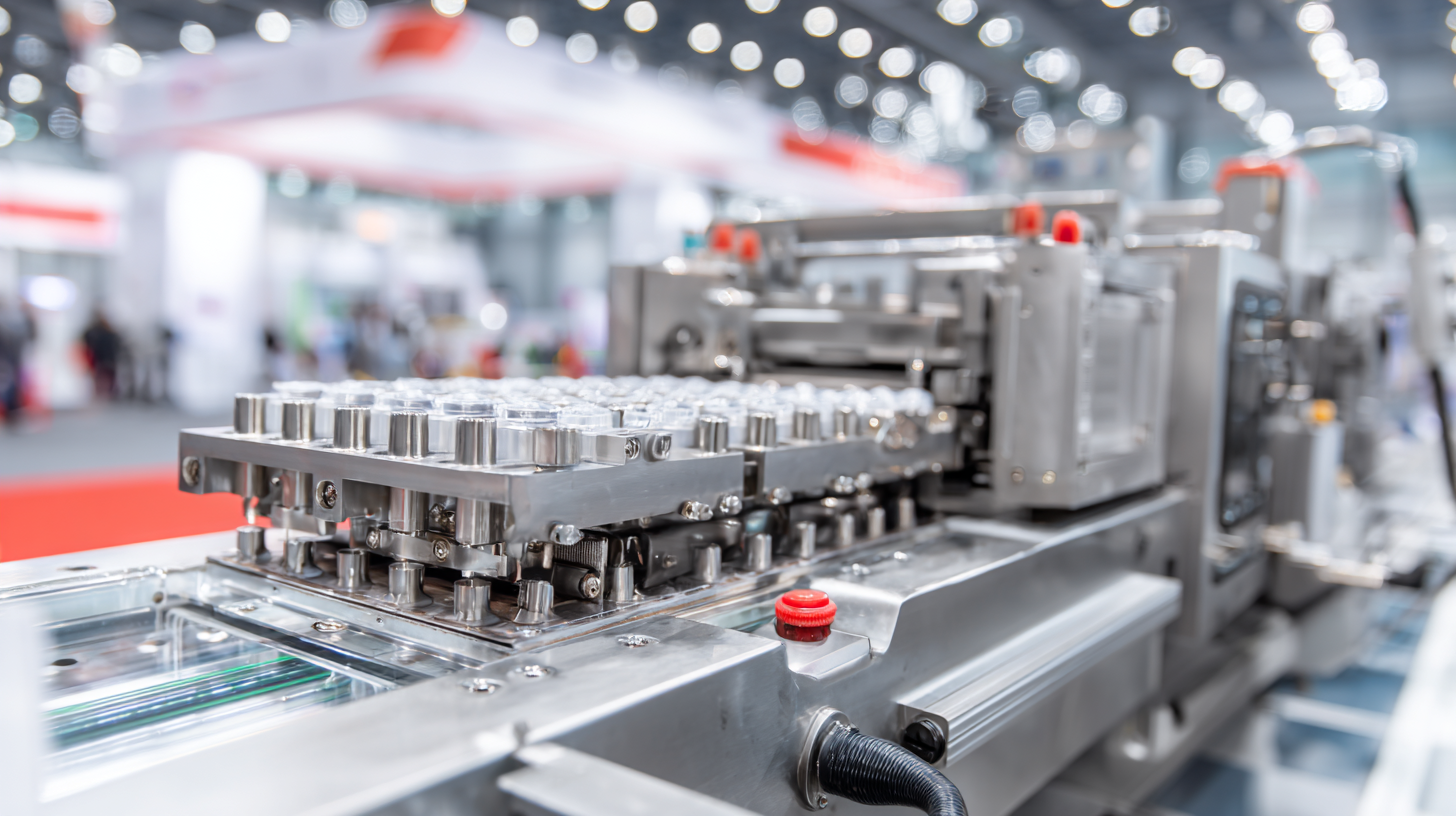

At the 2025 China Import and Export Fair, several key players showcased innovative advancements in heat sealing machines for blister packaging, highlighting their contributions to modernizing the industry. According to a recent report by Mordor Intelligence, the blister packaging market is projected to grow at a CAGR of 6.5% from 2022 to 2028, driven by an increased demand for pharmaceutical and consumer products. As market leaders unveil their latest technologies, it is clear that efficiency and sustainability are at the forefront of developments.

Leading manufacturers, such as Bosch Packaging Technology and Uflex Ltd., presented their cutting-edge heat sealing solutions that not only enhance sealing speeds but also reduce material waste. A 2023 study by Smithers Pira indicates that advanced heat sealing methods can increase production efficiency by up to 30%, aligning with global sustainability goals. This transformative technology is expected to benefit various sectors, including food and pharmaceuticals, enabling businesses to meet consumer demands while adhering to stringent safety standards. These innovations are marking a significant shift in industry trends, setting new benchmarks for packaging solutions in an ever-evolving market.

Related Posts

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

-

7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Exploring the Future of Packaging Systems at China Import and Export Fair 2025: Insights and Innovations