Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

In the rapidly evolving packaging industry, efficiency and innovation are crucial for meeting consumer demands and maintaining competitive advantage. The blister heat sealing machine has emerged as a game-changer, enabling manufacturers to streamline their packaging processes and enhance product protection. According to a report by Smithers Pira, the global market for blister packaging is predicted to reach $22.5 billion by 2025, driven by the rising demand for pharmaceutical and food products that require secure and sterile packaging solutions. Blister heat sealing machines play a pivotal role in this growth by offering high-speed sealing capabilities, precision in production, and reduced material waste. As industries increasingly focus on automation and sustainability, the adoption of blister heat sealing technology is reshaping how products are packaged, ensuring greater efficiency and reduced operational costs. This revolution in packaging not only benefits manufacturers but also enhances the overall consumer experience by providing safer and more reliable product delivery.

Understanding the Basics of Blister Heat Sealing Technology

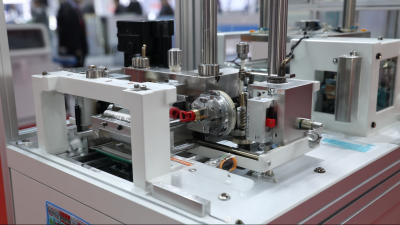

Blister heat sealing technology has emerged as a transformative force in the packaging industry, providing a reliable and efficient method for enclosing products securely. This technique utilizes heat to create airtight seals between packaging materials, significantly enhancing shelf life and product integrity. Understanding the fundamentals of blister heat sealing involves grasping the mechanics behind its operation: the process typically involves heating the sealing film until it melts and adheres to the pre-formed blister while ensuring that the product remains protected and undamaged.

As industries continue to prioritize efficiency and sustainability, blister heat sealing technology is being refined to meet these growing demands. Innovations in machinery and sealing materials contribute to a reduction in waste and energy consumption, aligning with broader goals of resource efficiency in manufacturing. This evolution not only benefits the packaging industry but also serves industries like pharmaceuticals and food, where product safety and preservation are paramount. The ongoing development in blister sealing technology indicates a promising future, potentially unmatched by traditional packaging methods due to its ability to adapt quickly to various materials and design requirements.

Identifying the Key Benefits of Blister Heat Sealing Machines

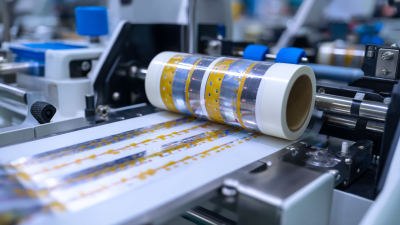

Blister heat sealing machines have transformed packaging industries by offering several key benefits that significantly enhance productivity and product integrity. One of the primary advantages is their ability to create airtight seals that protect products from contamination and extend shelf life. This is particularly crucial in sectors like pharmaceuticals and food packaging, where freshness and safety are paramount. The precision of blister packaging ensures that each item is securely contained, reducing the risk of damage during transportation.

In addition to product protection, blister heat sealing machines also streamline the packaging process, thereby reducing labor costs and increasing production speed. These machines can handle high volumes of packaging while maintaining consistent quality, thereby minimizing waste and optimizing resource use. Furthermore, their versatility allows manufacturers to create various package sizes and designs, catering to diverse product requirements. With the implementation of these advanced sealing technologies, businesses not only enhance efficiency but also improve their competitive edge in the market.

Maximizing Efficiency: Key Benefits of Blister Heat Sealing Machines

Implementing Blister Heat Sealing in Your Packaging Line

Implementing blister heat sealing in your packaging line can significantly enhance operational efficiency and product integrity. Blister heat sealing technology offers a reliable method for packaging a variety of products, from pharmaceuticals to electronics. By creating airtight seals, this process not only extends shelf life but also provides superior protection against contamination and damage. When integrating this machinery into your packaging line, it’s important to assess the specific needs of your products and workflow to optimize performance.

To successfully incorporate blister heat sealing, consider the design of your packaging and choose the right materials that align with your product specifications. Training your staff on the proper operation of the machines is crucial for maintaining high-quality outputs and minimizing downtime. Additionally, regular maintenance and timely upgrades to your sealing machines are necessary to keep pace with technological advancements, ensuring you stay competitive in the packaging industry. By investing in this efficient packaging solution, companies can streamline their processes and ultimately reduce costs while enhancing product presentation and safety.

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries

| Parameter | Description | Benefit |

|---|---|---|

| Machine Type | Automatic and Semi-Automatic | Increased production speed |

| Sealing Temperature | 150°C - 200°C | Prevents material degradation |

| Materials Compatible | PVC, PET, and more | Versatile packaging solutions |

| Production Rate | Up to 60 cycles per minute | Higher throughput efficiency |

| Energy Consumption | Low energy consumption models available | Cost-efficient operation |

| Safety Features | Emergency stop, protective guards | Enhanced worker safety |

Troubleshooting Common Issues with Blister Heat Sealing Machines

Blister heat sealing machines have become indispensable in the packaging industry, offering efficiency and precision in producing sealed packages. However, like any machinery, users may encounter common issues that can disrupt operation. One significant problem is improper temperature settings, which can lead to inadequate sealing. According to a report by Smithers Pira, nearly 30% of packaging failures can be traced back to inconsistent temperature control. Regularly calibrating the thermocouples and checking the heating elements can help mitigate such issues.

Another prevalent challenge is the quality of the sealing material itself. A study from the Packaging Machinery Manufacturers Institute (PMMI) indicates that the wrong type of foil or film can compromise the integrity of the seal, often resulting in leaks or product exposure. Ensuring compatibility between the sealing materials and the machine, as well as conducting regular maintenance on the sealing heads, can significantly enhance operational efficiency. By addressing these common issues proactively, manufacturers can achieve a streamlined packaging process and maintain product integrity, thereby optimizing their production lines.

Exploring Future Trends in Blister Heat Sealing Innovations

Blister heat sealing machines are at the forefront of packaging innovation, offering unprecedented efficiency and adaptability in various industries. As manufacturers strive to meet increasing consumer demands for speed and sustainability, future trends in blister heat sealing technology are poised to reshape packaging processes. These advancements include the integration of smart automation and IoT capabilities, allowing machines to optimize production in real-time by monitoring performance metrics and reducing waste.

Blister heat sealing machines are at the forefront of packaging innovation, offering unprecedented efficiency and adaptability in various industries. As manufacturers strive to meet increasing consumer demands for speed and sustainability, future trends in blister heat sealing technology are poised to reshape packaging processes. These advancements include the integration of smart automation and IoT capabilities, allowing machines to optimize production in real-time by monitoring performance metrics and reducing waste.

Moreover, sustainability is becoming a key focus in blister heat sealing innovations. With growing concerns over plastic waste, manufacturers are exploring biodegradable materials and eco-friendly sealing methods. This shift not only addresses environmental issues but also aligns with consumer preferences for sustainable products. As the packaging industry continues to evolve, blister heat sealing machines will likely employ cutting-edge technologies such as advanced heat control systems and recyclable materials, ensuring that efficiency and sustainability go hand in hand.

Related Posts

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

-

Innovative Heat Sealing Machine for Blister Packaging Revolutionizes Industry Trends at 2025 China Import and Export Fair

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

How to Choose the Right Packaging Systems for Your Business Needs