How to Optimize Your Production Line with a Tray Sealer Packaging Machine

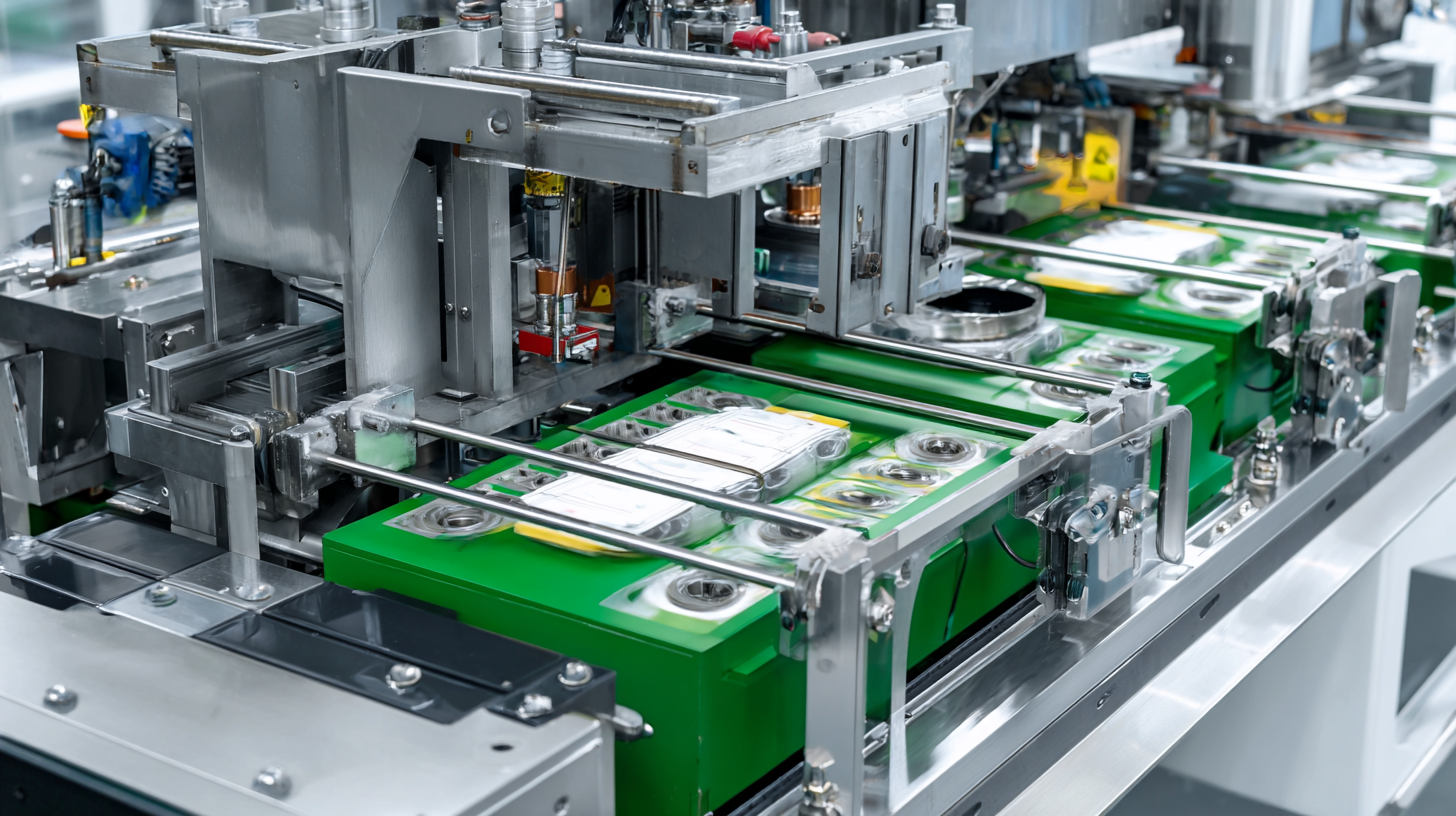

In the competitive landscape of manufacturing, efficiency and product quality are paramount. One key component that can significantly enhance these factors is the tray sealer packaging machine. As businesses continuously seek innovative solutions for optimizing their production lines, the integration of this technology can lead to remarkable improvements in both speed and consistency.

By sealing products securely in trays, manufacturers can maintain freshness, reduce spoilage, and streamline the packing process, all while minimizing labor costs. This article will delve into the best practices for implementing a tray sealer packaging machine effectively, exploring its benefits, operational techniques, and the potential impact on overall productivity.

Whether you're a seasoned industry professional or a newcomer looking to enhance your production capabilities, understanding how to optimize your operations with this essential machinery will provide a crucial competitive edge.

Assessing Your Current Production Line Setup for Optimization Opportunities

When considering how to optimize your production line, a thorough assessment of your current setup is essential. Many companies overlook the importance of analyzing their existing processes before implementing new machinery. According to a report by the International Society for Automation (ISA), around 60% of organizations can gain efficiency by simply reevaluating their current workflows. This highlights the need for a systematic approach in identifying inefficiencies.

Incorporating a tray sealer packaging machine can significantly enhance your production line if integrated properly. The Food and Beverage industry, for instance, reports that companies utilizing advanced packaging solutions can reduce packaging labor costs by up to 30%. This data underscores the importance of not only evaluating the machinery options but also understanding how they fit with the overall process. By focusing on automation and efficiency, businesses can streamline operations, minimize waste, and ultimately boost productivity. Identifying bottlenecks and areas for improvement allows for smarter investments in equipment that align with both current needs and future growth strategies.

Understanding the Benefits of Tray Sealers in Streamlining Operations

Tray sealers play a crucial role in modern production lines, offering a range of benefits that help streamline operations and enhance efficiency. One of the primary advantages of using tray sealers is their ability to maintain product integrity. These machines provide a tight seal that protects food from contamination and spoilage, ensuring that products remain fresh for a longer time. This is particularly important in industries where hygiene and safety are paramount, as tray sealers help reduce waste and minimize the risk of recalls.

In addition to preserving product quality, tray sealers also contribute to faster processing times. With automated sealing capabilities, these machines can significantly increase production rates compared to manual sealing methods. This not only boosts output but also frees up employees to focus on other essential tasks, ultimately leading to improved workflow. Furthermore, the versatility of tray sealers enables them to accommodate various packaging designs and materials, making them adaptable to different product lines without requiring extensive reconfiguration. This flexibility supports businesses in meeting diverse customer demands while optimizing their overall production efficiency.

Choosing the Right Tray Sealer for Your Production Needs

Choosing the right tray sealer for your production needs is crucial for optimizing efficiency and maintaining product integrity. According to a recent report by Smithers Pira, the global market for food packaging is expected to reach $429 billion by 2026, with tray sealers playing a significant role in this growth. As companies seek to streamline operations and enhance shelf-life, understanding the features and capabilities of various tray sealing machines becomes essential.

When selecting a tray sealer, consider the following tips: First, evaluate the types of materials you plan to use. Different machines are designed for specific materials—such as plastic, aluminum, or paperboard—so ensure compatibility with your product packaging. Additionally, look for machines that offer flexibility in size and shape to accommodate a diverse product range. A machine that allows for quick changeovers can significantly reduce downtime, enhancing productivity.

Another key factor is the machine’s sealing technology. Consistent and reliable seals are vital for reducing spoilage rates and ensuring consumer satisfaction. According to industry benchmarks, a properly calibrated tray sealer can achieve seal strengths exceeding 90%, which is essential for maintaining product freshness. By prioritizing these elements, businesses can effectively choose the right tray sealer that meets their production requirements and enhances the overall packaging process.

Implementing Best Practices for Efficient Tray Sealing Processes

When optimizing your production line with a tray sealer packaging machine, implementing best practices for efficient tray sealing processes is crucial. Start by ensuring that your machine is properly calibrated for the specific materials and product dimensions being used. Regular maintenance and adjustments can significantly reduce downtime and increase operational efficiency. Additionally, train your staff on the proper operation of the tray sealer to minimize errors and enhance productivity.

**Tips:**

1. Utilize real-time monitoring systems to track the performance of your tray sealer. This helps in identifying bottlenecks and effectively addressing them.

2. Consider automation options to streamline the sealing process. Automated systems can handle higher volumes and reduce manual labor costs, leading to a more efficient workflow.

Integrating feedback loops within your production line can also enhance the sealing process. Encourage operators to communicate any issues directly to the management team for quick resolutions. Creating an environment where continuous improvement is prioritized will ensure your tray sealing processes are always optimized for maximum efficiency.

How to Optimize Your Production Line with a Tray Sealer Packaging Machine - Implementing Best Practices for Efficient Tray Sealing Processes

| Parameter | Value | Importance |

|---|---|---|

| Sealing Temperature | 180°C | Crucial for effective sealing |

| Production Speed | 30 packs/min | Effects throughput |

| Material Type | Plastic PET | Affects durability |

| Seal Width | 8 mm | Impacts seal integrity |

| Maintenance Frequency | Monthly | Maintains performance |

| Energy Consumption | 5 kWh | Cost efficiency measure |

Maintaining and Troubleshooting Your Tray Sealer for Longevity and Performance

A tray sealer packaging machine is an essential asset for optimizing production lines, ensuring efficiency and preserving product quality. However, to maintain optimal performance and longevity, it is crucial to adopt proactive maintenance and troubleshooting strategies. According to a report by Grand View Research, the global packaging machinery market is projected to reach $50.9 billion by 2025, emphasizing the significance of maintaining advanced packaging equipment like tray sealers.

Regular cleaning and inspection are foundational to ensuring that your tray sealer operates smoothly. Tips for effective maintenance include checking seals for wear and tear, regularly calibrating the machine to avoid inaccuracies, and ensuring that the heating elements are functioning correctly. These actions can prevent costly downtimes—research shows that unplanned maintenance can lead to losses averaging $22,000 per hour in manufacturing environments.

In addition to routine checks, troubleshooting common issues promptly can extend the life of your tray sealer. Keep an eye out for inconsistencies in sealing, as this can be indicative of temperature settings or pressure issues. It's advisable to maintain a detailed log of machine performance to identify patterns that may require attention. Implementing these strategies not only enhances machine performance but also can lead to a significant return on investment, with companies reporting up to 25% increased efficiency after optimizing their equipment management processes.

Related Posts

-

7 Essential Tips to Optimize Your Tray Sealer Packaging Machine Efficiency

-

How to Choose the Best Tray Packaging Machine for Your Business Needs

-

How to Optimize Blister Thermoforming for Maximum Efficiency and Cost Savings in Packaging

-

Unlocking the Future of Packaging Automation with Digital Innovations

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business