Revolutionizing Sustainability: The Future of Thermoformed Plastic Packaging Solutions

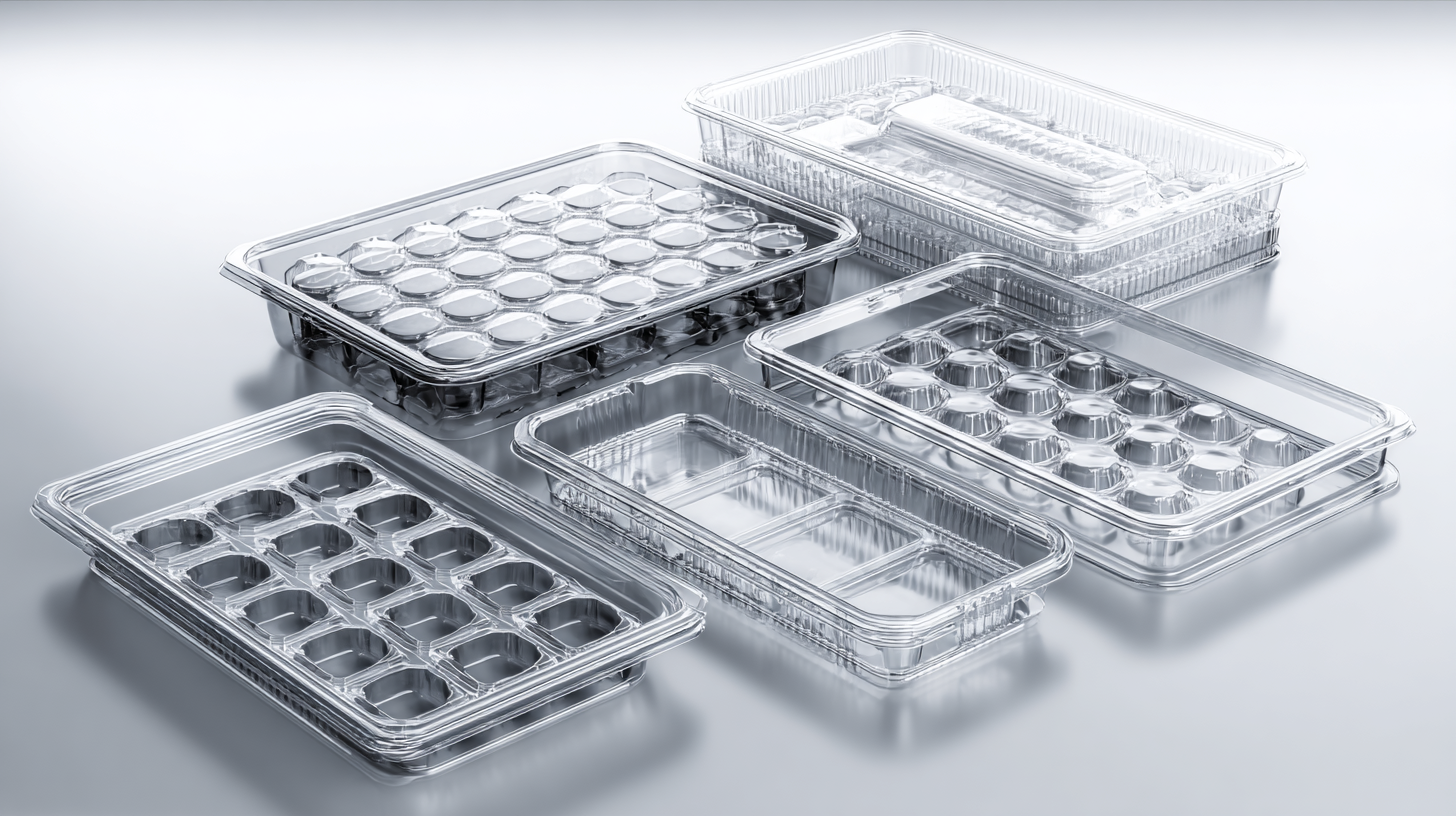

As the world continues to grapple with environmental challenges, the demand for sustainable packaging solutions has never been more pressing. Among innovative approaches, thermoformed plastic packaging stands out as a game-changer that aligns with eco-friendly initiatives while maintaining functionality and versatility. This guide aims to explore how thermoformed plastic packaging can revolutionize sustainability in various industries by providing lightweight, durable, and recyclable options that reduce waste and carbon footprint. By leveraging advanced technologies and materials, businesses can not only meet consumer expectations for sustainability but also enhance their brand reputation and operational efficiency.

Join us as we delve into the various strategies and best practices that organizations can adopt to integrate thermoformed plastic packaging into their sustainability journey, paving the way for a greener future.

Understanding the Role of Thermoformed Plastics in Sustainable Packaging Solutions

Thermoformed plastics are increasingly being recognized for their pivotal role in advancing sustainable packaging solutions. By utilizing techniques that mold plastic sheets into diverse forms, thermoforming offers the advantage of lightweight structures that reduce material usage and transportation emissions. Moreover, many thermoformed plastics are compatible with recycling processes, which allows for a circular economy approach where materials can be reused, thus minimizing waste and environmental impact.

In addition to their recycling potential, thermoformed plastics can be produced from sustainable sources, such as bioplastics derived from renewable resources. This not only decreases reliance on fossil fuels but also contributes to lower carbon footprints throughout the production lifecycle. As consumer demand shifts toward environmentally friendly packaging, the integration of thermoformed plastics in retail and food service sectors highlights their adaptability and capacity to meet both functional and ecological requirements. With ongoing innovations in this field, the future of thermoformed plastic packaging looks promising, fostering sustainability while fulfilling market needs.

Revolutionizing Sustainability: The Future of Thermoformed Plastic Packaging Solutions

| Material Type | Recyclability | Biodegradability | Market Application | Carbon Footprint (kg CO2e/kg) | Average Cost ($/kg) |

|---|---|---|---|---|---|

| PET (Polyethylene Terephthalate) | Yes | No | Food Containers | 2.4 | 1.50 |

| PS (Polystyrene) | Limited | No | Packaging, Disposable Cups | 3.3 | 1.20 |

| PLA (Polylactic Acid) | Yes | Yes (Industrial Composting) | Biodegradable Containers | 1.8 | 2.50 |

| PP (Polypropylene) | Yes | No | Food Packaging, Automotive Parts | 1.5 | 1.00 |

| PVC (Polyvinyl Chloride) | Yes | No | Construction, Packaging | 2.5 | 1.30 |

Evaluating Environmental Impacts: Comparing Thermoformed Plastics to Traditional Materials

The shift towards sustainable packaging solutions is more critical than ever, and thermoformed plastics have emerged as a strong alternative to traditional materials. Evaluating environmental impacts reveals that thermoformed plastics are often more efficient in terms of resource use, energy consumption, and waste generation. Unlike conventional materials such as glass or metals, thermoformed plastics can be produced using less energy and can be molded into various shapes with minimal waste, thus reducing their overall carbon footprint during production.

Furthermore, the recyclability of thermoformed plastics presents a significant advantage. Many modern thermoformed products are made from recyclable materials, allowing them to re-enter the supply chain effectively. This contrasts with traditional materials, which may require more complex recycling processes or end up in landfills. By comparing the lifecycle of thermoformed plastics to that of traditional packaging materials, it becomes evident that the former not only minimizes environmental impact but also aligns with a circular economy model, promoting sustainability in consumption and production practices.

Innovative Design Strategies for Enhancing Sustainability in Thermoformed Packaging

Thermoformed plastic packaging has seen significant advancements in recent years, primarily driven by the need for sustainable solutions. Innovative design strategies are crucial for enhancing sustainability throughout the lifecycle of these materials. According to a report from the Plastics Industry Association, nearly 30% of all plastic packaging is not recycled, underscoring the urgent need for innovative approaches that not only focus on design but also on recyclability and material sourcing. By integrating bio-based materials and utilizing energy-efficient manufacturing processes, companies can create packaging that reduces environmental impact without sacrificing quality.

Tips: When designing thermoformed packaging, consider the use of mono-material structures that facilitate recycling. Simplifying the materials used helps streamline the recycling process, making it easier for consumers to dispose of packaging responsibly. Additionally, leverage advanced design technologies, such as 3D printing and computer-aided design (CAD), to optimize packaging shapes, minimize material usage, and enhance performance, thereby reducing waste.

Investing in research and collaboration is vital for advancing sustainability in the thermoformed packaging sector. Industry leaders are increasingly turning to partnerships focused on developing innovative materials that are biodegradable or made from recycled content. A report by the Ellen MacArthur Foundation revealed that transitioning to a circular economy could create $1 trillion in economic opportunities while reducing the environmental footprint of packaging. Embracing these collaborative strategies is essential for driving meaningful progress toward a more sustainable future in polymer packaging.

Implementing Advanced Technologies for Efficient Thermoforming Processes

The future of thermoforming technology is being transformed by the implementation of advanced processes that enhance efficiency and sustainability. Research into optimizing the thermoforming process for straw-based biodegradable materials offers significant potential for converting biomass into high-value products. This innovative approach not only addresses the growing need for sustainable packaging solutions but also aligns with global efforts to reduce plastic waste. By combining biological mechanical processing and simulation, manufacturers can improve the properties of these biodegradable materials, making them viable alternatives to traditional plastics.

Moreover, advancements in additively reinforced thermoforming (ART) technology are crucial for boosting the performance of materials like polyethylene terephthalate glycol (PETG). Recent studies indicate that ART can significantly enhance the thermomechanical properties of thermoformed sheets, facilitating their use in a variety of applications, including the medical sector. This evolution in thermoforming techniques is also driven by the increasing demand for rigid thermoform plastic packaging in the U.S., a market characterized by robust growth across diverse sectors. Innovations such as Watttron’s new thermoforming process, which conserves packaging material by up to 50%, exemplify the industry's commitment to efficiency and sustainability, ensuring that the future of packaging is not only functional but also environmentally responsible.

Future Trends: What to Expect in Thermoforming and Sustainable Packaging Solutions

The future of thermoformed plastic packaging solutions is intrinsically tied to sustainability, with high melt strength polypropylene (HMS PP) emerging as a pivotal material. According to market analysis, the HMS PP sector is poised for significant growth, driven by its applications in diverse fields such as packaging, automotive, and healthcare. By 2034, the vacuum packaging market is projected to reach substantial dimensions, underscoring the increasing demand for eco-friendly solutions in food preservation and logistics. This shift indicates a marked preference for sustainable practices in manufacturing processes.

Tips: When considering sustainable packaging options, it's essential to evaluate the material's recyclability and overall environmental impact. Industries must also keep abreast of trends like lightweight materials and innovative manufacturing techniques, which are expected to revolutionize packaging solutions.

Moreover, the market for low-density polyethylene (C6-LLDPE) is anticipated to expand, with expectations of reaching 25,094.28 million units by 2033. This growth highlights the shift towards materials that provide both performance and sustainability, catering to the rising consumer demand for environmentally conscious products. Emphasizing sustainable packaging will not only fulfill regulatory requirements but also elevate brand image among eco-aware consumers.

Related Posts

-

How to Choose the Best Tray Packaging Machine for Your Business Needs

-

Innovative Examples of Packaging Equipment Transforming Global Supply Chains

-

Common Issues Faced by Businesses Using Food Packaging Machine

-

7 Compelling Reasons to Choose Tray Packaging for Your Business Success

-

Exploring the Future of Packaging Systems at China Import and Export Fair 2025: Insights and Innovations

-

Unlocking the Future of Packaging Automation with Digital Innovations