Revolutionizing Efficiency: How Thermoforming Blister Packaging Machines Boost Production by 30%

In the fast-paced landscape of manufacturing, the demand for efficiency and productivity is ever-increasing. Among the innovations that address these needs, the thermoforming blister packaging machine has emerged as a game-changer, enabling companies to enhance production rates by an impressive 30%. According to a report from Smithers Pira, the global market for blister packaging is projected to reach $14.5 billion by 2025, driven by its advantages in reducing material waste and lowering costs. This surge underscores the importance of adopting advanced packaging technologies within various sectors, including pharmaceuticals, food, and consumer goods. The thermoforming process not only streamlines production lines but also offers versatility and improved product protection, making it a critical asset for manufacturers aiming to maintain a competitive edge in today's economy.

In the fast-paced landscape of manufacturing, the demand for efficiency and productivity is ever-increasing. Among the innovations that address these needs, the thermoforming blister packaging machine has emerged as a game-changer, enabling companies to enhance production rates by an impressive 30%. According to a report from Smithers Pira, the global market for blister packaging is projected to reach $14.5 billion by 2025, driven by its advantages in reducing material waste and lowering costs. This surge underscores the importance of adopting advanced packaging technologies within various sectors, including pharmaceuticals, food, and consumer goods. The thermoforming process not only streamlines production lines but also offers versatility and improved product protection, making it a critical asset for manufacturers aiming to maintain a competitive edge in today's economy.

The Role of Thermoforming in Modern Packaging Efficiency

Thermoforming technology has emerged as a game changer in modern packaging, delivering unprecedented efficiency and productivity gains. According to recent industry reports, companies utilizing thermoforming blister packaging machines have seen production increases of up to 30%. This leap in efficiency is attributed to the speed of the thermoforming process, which allows manufacturers to produce high volumes of customized packaging at a fraction of the time required by traditional methods. The ability to automate these processes not only accelerates production but also reduces labor costs, making it a preferred choice for many businesses looking to optimize their packaging operations.

Moreover, thermoforming plays a pivotal role in enhancing resource utilization and sustainability within the packaging sector. Studies indicate that materials used in thermoforming processes can lead to a significant reduction in waste—some estimates suggest a reduction by up to 40% compared to other packaging techniques. The versatility of thermoformed materials allows for lightweight and robust designs that meet modern consumer demands while minimizing environmental impact. As the packaging industry continues to focus on sustainability, thermoforming stands out as a crucial driver of both operational efficiency and eco-friendly practices.

Production Efficiency Before and After Implementing Thermoforming Blister Packaging Machines

This chart demonstrates the significant increase in production efficiency before and after the adoption of thermoforming blister packaging machines, illustrating an impressive 30% boost in production capability.

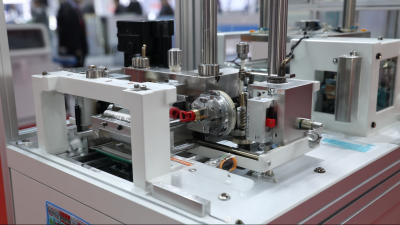

Key Features of Blister Packaging Machines That Enhance Production

Blister packaging machines are transforming the production landscape by incorporating advanced features that enhance efficiency and output. One of the key innovations is the integration of automated feed systems, which significantly streamline the process. According to a report by Smithers Pira, companies using automated blister machines have reported productivity increases of up to 30%. This automation not only reduces labor costs but also minimizes human error, which is crucial in maintaining the quality of packaging in pharmaceuticals and consumer products.

Blister packaging machines are transforming the production landscape by incorporating advanced features that enhance efficiency and output. One of the key innovations is the integration of automated feed systems, which significantly streamline the process. According to a report by Smithers Pira, companies using automated blister machines have reported productivity increases of up to 30%. This automation not only reduces labor costs but also minimizes human error, which is crucial in maintaining the quality of packaging in pharmaceuticals and consumer products.

Another essential feature is the adoption of energy-efficient technology, which not only decreases operational costs but also contributes to sustainability goals. The latest machines utilize optimized heating systems that ensure uniform temperature distribution, thereby improving the forming process. A study conducted by the Packaging Institute noted that energy-efficient blister packaging systems can decrease energy consumption by as much as 40%, allowing manufacturers to achieve higher production volumes without compromising on environmental responsibilities. These innovations in blister packaging technology are paving the way for industries to meet rising consumer demands while boosting their bottom lines.

Strategies to Optimize Production with Thermoforming Technology

The use of thermoforming bladder packaging machines is transforming production efficiency in various industries, leading to a 30% increase in output. To fully optimize production, companies must integrate thermoforming technology early in the product development process. This approach fosters collaboration across departments, ensuring that packaging solutions are designed with efficiency in mind from the outset. By aligning design choices with manufacturing capabilities, businesses can minimize bottlenecks and enhance overall workflow.

Additionally, a systematic review of PET circularity technologies highlights the need for a proactive stance on recycling strategies as they relate to thermoforming processes. While advancements in PET recycling have been promising, challenges regarding energy efficiency and cost must be addressed to create sustainable practices. A focus on innovative management strategies will be essential for overcoming these obstacles, allowing for the seamless integration of eco-friendly materials into production lines and bolstering the circular economy in packaging solutions.

Real-World Case Studies: Boosting Output by 30% with Innovative Packaging

In recent years, the packaging industry has witnessed innovative advancements that significantly enhance production efficiency. One standout example is the adoption of thermoforming blister packaging machines, which has been proven to boost output by up to 30%. According to a study by Smithers Pira, the demand for blister packaging is anticipated to grow at a CAGR of 6.6% between 2020 and 2025, driven by the increased need for automation and efficiency in the manufacturing process.

Real-world case studies highlight the effectiveness of these machines. For instance, a leading pharmaceutical company implemented a state-of-the-art thermoforming system that reduced production downtime by 15% while increasing the speed of packaging operations. This transition not only led to a higher output but also significantly improved the company's ability to meet tight delivery schedules. Additionally, the integration of advanced quality control systems within these machines ensures that products are packaged reliably and consistently, reducing waste and maximizing profitability. These developments illustrate the transformative impact of innovative packaging solutions on operational efficiency in various sectors.

Tips for Choosing the Right Blister Packaging Machine for Your Needs

When considering the investment in blister packaging machines, it's essential to choose the right model that aligns with your production needs. According to industry reports, thermoplastic packaging technologies can enhance productivity by up to 30%, making it crucial for businesses to select machines that optimize both efficiency and flexibility.

Many companies have seen dramatic improvements in output and reduction in waste by upgrading their equipment to innovative thermoforming solutions.

Many companies have seen dramatic improvements in output and reduction in waste by upgrading their equipment to innovative thermoforming solutions.

Tips for Choosing the Right Blister Packaging Machine for Your Needs: First, assess your production volume requirements. Machines that can handle higher outputs without compromising quality are ideal for large-scale operations. Second, consider the types of materials you will be using. A versatile machine capable of processing different plastics will give you greater flexibility in packaging options. Lastly, think about the ease of operation and maintenance. A user-friendly machine will reduce downtime and training costs, ultimately boosting your overall production efficiency.

The right blister packaging machine not only contributes to immediate productivity gains but also supports long-term growth by adapting to changing market demands and consumer expectations. The investment should align with your strategic goals, ensuring that your operations remain competitive and efficient in a dynamic marketplace.

Related Posts

-

Ultimate Guide to Choosing the Right Blister Heat Sealing Machine for Your Packaging Needs

-

Innovative Heat Sealing Machine for Blister Packaging Revolutionizes Industry Trends at 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing the Right Plastic Tray Sealing Machine for Your Business

-

Innovative Examples of Packaging Equipment Transforming Global Supply Chains

-

How to Optimize Your Production Line with a Tray Sealer Packaging Machine

-

7 Best Plastic Tray Sealing Machines to Elevate Your Packaging Efficiency