Top 5 Blister Sealing Machines for Efficient Packaging Solutions

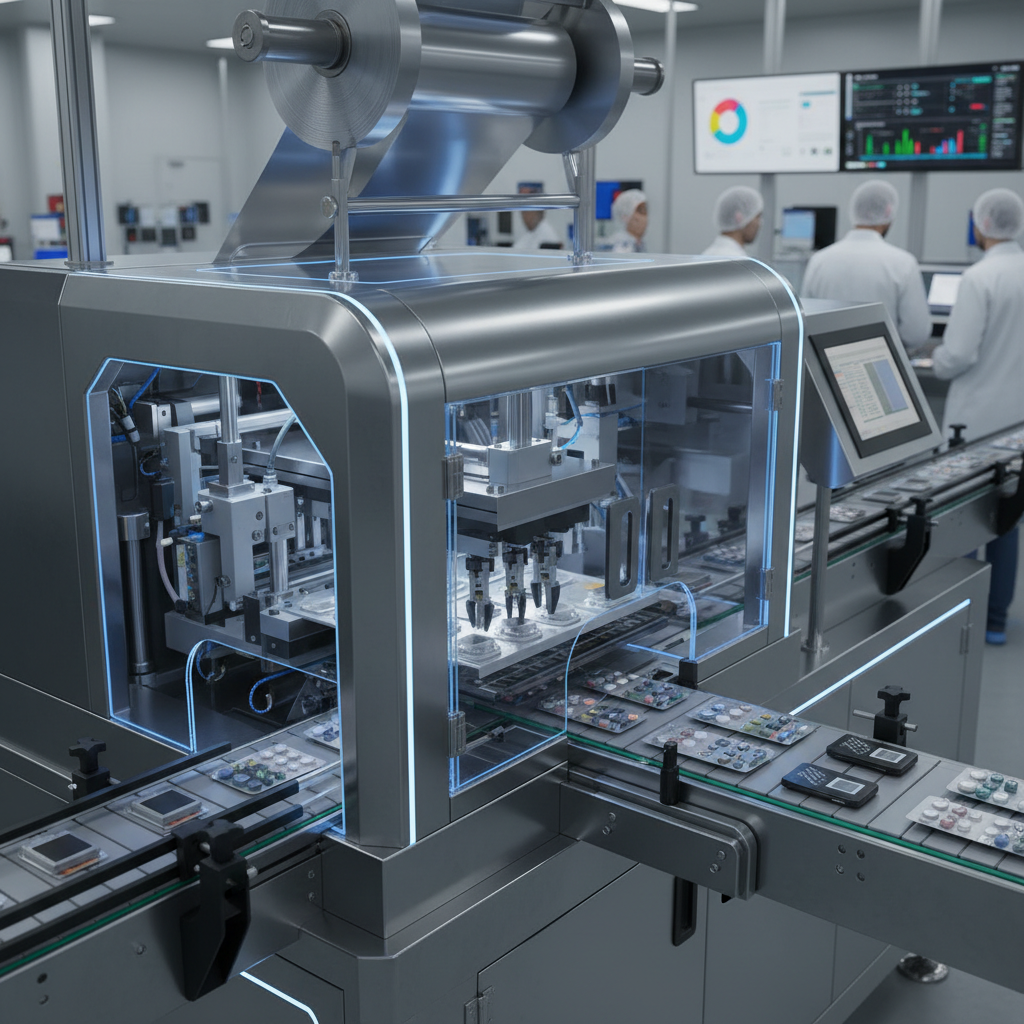

In the fast-evolving landscape of packaging technology, blister sealing machines have emerged as essential tools for achieving optimal efficiency and reliability in product packaging. According to a recent report by ResearchAndMarkets, the global blister packaging market is projected to reach $30 billion by 2026, growing at a CAGR of 6.2%. This growth underscores the increasing need for versatile and efficient blister sealing solutions across various industries, including pharmaceuticals, food, and consumer goods.

Industry expert Dr. Emily Chen, a leading authority on packaging technology, emphasizes the importance of innovation in this sector. She states, "The right blister sealing machine not only enhances product protection but also significantly reduces operational costs." As manufacturers strive to deliver high-quality products while maintaining cost-effectiveness, the selection of the right blister sealing machine becomes a critical factor in ensuring sustainable production practices.

In this article, we will explore the top five blister sealing machines available on the market today, highlighting their unique features and benefits that cater to the evolving needs of businesses. By understanding these efficient packaging solutions, companies can make informed decisions that support their growth and operational efficiency.

Top 5 Innovative Blister Sealing Machines for Modern Packaging Needs

In the rapidly evolving landscape of packaging technology, innovative blister sealing machines have become indispensable for modern manufacturing processes. According to a report from MarketsandMarkets, the global blister packaging market is projected to reach USD 41.75 billion by 2026, driven by the growing demand for efficient, cost-effective packaging solutions across various sectors, including pharmaceuticals, food, and consumer goods. This surge underscores the need for advanced blister sealing machines that not only enhance performance but also ensure product integrity and safety.

One of the most notable advancements in blister sealing technology is the integration of smart features, such as IoT connectivity and automation. These enhancements allow for real-time monitoring and analysis of the sealing process, improving efficiency and reducing waste. A study by Research and Markets highlights that automation in packaging processes can lead to a 30% increase in output while minimizing errors. Manufacturers are increasingly seeking machines equipped with cutting-edge technology that can adapt to diverse product types and varying production scales, ensuring they meet the dynamic needs of today's market. The adoption of innovative blister sealing solutions is thus a key factor in achieving operational excellence and staying competitive in an ever-changing industry.

Key Features to Look for in High-Performance Blister Sealing Equipment

When selecting a blister sealing machine, one must consider several key features that dictate performance and efficiency. Firstly, the machine's sealing temperature control is vital; it ensures that the materials are sealed at optimal temperatures to prevent damage to the product while achieving a strong bond. Look for equipment with digital temperature settings for precision.

Another critical feature is the speed of the machine. High-performance blister sealing equipment should be capable of producing a significant number of seals per hour, making it suitable for commercial packaging needs. Machines that allow for easy adjustments in speed offer flexibility for varying production requirements, ultimately saving time and reducing costs.

Tips: Always check the machine's energy efficiency ratings. An energy-efficient model may have a higher upfront cost but can lead to significant savings on operational costs over time. Additionally, consider the ease of maintenance; machines that are simple to clean and service not only reduce downtime but also extend the lifespan of the equipment. Investing in a machine that incorporates user-friendly interfaces can greatly enhance operational efficiency and reduce the learning curve for staff.

Evaluating Production Speed: How Fast Can Blister Sealing Machines Operate?

Blister sealing machines are pivotal in optimizing production speed within the packaging industry, ensuring that products are securely sealed while maintaining efficiency. Recent industry reports indicate that high-speed blister sealing machines can operate at rates of up to 100 cycles per minute, depending on the complexity of the product being packaged. This rapid output is essential for manufacturers aiming to meet growing consumer demands and competitive market pressures.

When evaluating the efficiency of blister sealing machines, it’s crucial to consider not just speed but also versatility. Machines that can accommodate various blister types—such as face seal, trap seal, and die-cut blisters—allow manufacturers to adjust to different packaging needs without significant downtime. According to a study by the Packaging Machinery Manufacturers Institute, companies that invest in multi-functional sealing machines can realize an increase in productivity by as much as 20%.

Tips: To maximize the operation speed of blister sealing machines, regular maintenance is key. Ensure that machinery parts are lubricated and calibrated to prevent slowdowns caused by wear and tear. Additionally, training operators on quick setup procedures can significantly enhance production efficiency, making the most of the machinery's capabilities.

Understanding Cost Efficiency: Analyzing ROI for Blister Packaging Solutions

When considering blister packaging solutions, understanding the return on investment (ROI) becomes crucial for businesses aiming to optimize their operational efficiency. The initial investment in blister sealing machines can be significant, but the potential savings and benefits they offer often justify the costs. These machines not only enhance packaging speed and precision but also reduce material waste, which contributes to long-term savings. Analyzing how these factors play into the overall cost efficiency of the production process can provide insights into the true value of investing in quality blister packaging systems.

Moreover, the scalability of blister sealing machines can further improve ROI. As production demands fluctuate, modular and adjustable machines enable businesses to meet varying output requirements without incurring excessive costs. This adaptability helps in maintaining consistent quality while minimizing downtime, thus fostering a more efficient workflow. As companies evaluate their packaging strategies, a thorough analysis of the ROI associated with blister sealing machines can reveal significant financial advantages, making them a worthwhile consideration in improving packaging efficiency.

Best Practices for Maintenance and Longevity of Blister Sealing Machines

Maintenance and longevity of blister sealing machines are vital for ensuring efficiency and effectiveness in packaging solutions. Regularly inspecting and calibrating the equipment is essential to maintain optimal performance, as this helps prevent deviations that could lead to sealing failures. Operators can enhance the lifespan of these machines by keeping them clean and free from contaminants, as dirt and particulates can interfere with the sealing process and compromise package integrity.

Moreover, maintaining consistent sealing temperatures is crucial for achieving reliable seals. Discrepancies in heat settings can result in weak seals and product waste, prompting suppliers to advocate for standardized temperature management throughout the sealing process. Continuous training for operators on best practices, along with proactive troubleshooting measures, will further ensure that blister sealing machines function at peak efficiency, ultimately supporting the growing innovations in blister packaging and meeting the demands of modern pharmaceuticals.

Related Posts

-

7 Best Practices for Optimizing Your Blister Sealing Machine Efficiency

-

2025 Top Blister Pack Sealing Machine: Innovations & Best Practices

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

Revolutionizing Efficiency: How Thermoforming Blister Packaging Machines Boost Production by 30%

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

Maximizing Efficiency: How Blister Heat Sealing Machines Revolutionize Packaging Industries