Unlocking Efficiency: The Future of Blister Packaging Equipment in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of blister packaging equipment has grown exponentially, driven by the increasing demand for efficient and reliable packaging solutions across various industries. According to a report by Grand View Research, the global blister packaging market was valued at approximately $11.5 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. This growth is largely fueled by the pharmaceutical sector, where effective packaging is crucial for protecting sensitive products and ensuring compliance with stringent regulations.

Additionally, advancements in technology have escalated the capabilities of blister packaging equipment, enabling manufacturers to optimize production processes, reduce waste, and enhance product safety. As such, understanding the future trends and innovations in blister packaging equipment is vital for stakeholders aiming to unlock operational efficiencies and maintain competitiveness in this dynamic market.

The Evolution of Blister Packaging in the Manufacturing Landscape

The evolution of blister packaging in the manufacturing landscape has significantly impacted various industries, particularly in pharmaceuticals and consumer goods. According to a report by Mordor Intelligence, the blister packaging market was valued at approximately $16 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% through 2026. This growth is driven by the increasing demand for unit dose packaging that enhances product safety and extends shelf life. Modern blister packaging not only ensures product integrity but also offers convenience, making it a staple in the manufacturing process.

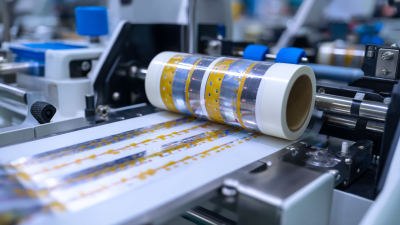

Moreover, advancements in blister packaging equipment are transforming manufacturing efficiency. Innovative machinery now integrates smart technology, allowing for real-time monitoring and precision in production. A Technavio report highlighted that the adoption of automated blister packaging machines could lead to a reduction in operational costs by up to 20%. As manufacturers seek to streamline operations and meet the rising consumer demand for eco-friendly solutions, the evolution of blister packaging equipment is set to play a crucial role in optimizing production lines and minimizing waste, paving the way for a more sustainable future in manufacturing.

Integrating Digital Technologies for Enhanced Blister Packaging Efficiency

The evolution of blister packaging equipment is increasingly intertwined with advancements in digital technologies, paving the way for enhanced operational efficiency in modern manufacturing. By integrating smart sensors, machine learning algorithms, and real-time data analytics, manufacturers can streamline production processes significantly. These technologies allow for precise monitoring of packaging performance, enabling proactive maintenance and minimizing downtime. As a result, companies are better equipped to respond to fluctuations in demand and optimize resource allocation.

Moreover, the implementation of digital tools facilitates improved quality control throughout the blister packaging cycle. Automated inspection systems can detect defects and inconsistencies faster than manual processes, ensuring that only compliant products reach consumers. This integration not only reduces waste but also contributes to higher consumer satisfaction by maintaining strict quality standards. As manufacturers harness the power of digital transformation, the future of blister packaging equipment looks promising, marked by greater efficiency, sustainability, and adaptability to the ever-changing market landscape.

Sustainability Trends Impacting Blister Packaging Equipment Design

Sustainability has emerged as a critical influence in the design of blister packaging equipment, driven by both regulatory pressures and evolving consumer expectations. Recent developments showcase a shift towards more eco-friendly materials, such as the introduction of perforated paper blisters that replace conventional plastic trays. This transition not only enhances recyclability but also aligns with the growing demand for sustainable solutions within the packaging industry. Manufacturers are now challenged to innovate their equipment to accommodate these thinner, alternative materials, fostering a commitment to sustainability without sacrificing functionality.

As companies adopt practical solutions like all-polypropylene blister packs, they are highlighting the balance between performance and environmental responsibility. These advancements are reshaping the landscape of packaging in various sectors, including pharmaceuticals, where sustainability is becoming a key factor in product design. With a market increasingly oriented towards greener alternatives, the future of blister packaging equipment appears poised for significant transformation, as industry players strive to meet consumer demands while adhering to stricter environmental standards.

Maximizing Productivity Through Automation in Blister Packaging Lines

As manufacturing processes evolve, the blister packaging industry is increasingly turning to automation to enhance productivity. According to a recent report by MarketsandMarkets, the global blister packaging market is projected to reach $28.85 billion by 2027, growing at a CAGR of 5.8%. This growth can be largely attributed to the integration of automated solutions that reduce manual handling and increase production speeds. These advancements not only streamline operations but also minimize human error, leading to higher quality outputs.

Moreover, a study by Research and Markets indicates that automated blister packaging machines can reduce packaging cycle times significantly, improving efficiency by up to 30%. By adopting smart technologies such as robotics and AI-driven systems, manufacturers can achieve higher output levels and maintain consistent packaging integrity. This shift towards automation not only maximizes throughput but also allows for better allocation of labor resources, enabling workers to focus on more complex tasks that require human intuition and problem-solving skills. As the industry continues to embrace these innovations, the future of blister packaging equipment appears poised for transformation, leading to unprecedented levels of efficiency.

Unlocking Efficiency: The Future of Blister Packaging Equipment

This chart illustrates the impact of automation on productivity in blister packaging lines, showcasing the increase in efficiency over the past five years.

Future Innovations in Blister Packaging: Trends to Watch for Ahead

As the landscape of modern manufacturing evolves, blister packaging equipment is poised for transformative innovations. According to a recent report by Smithers Pira, the blister packaging market is projected to reach $22.98 billion by 2025, driven by advancements in technology and growing demand for packaging solutions in pharmaceuticals and consumer goods. Innovations such as automation, enhanced material compatibility, and sustainability are becoming paramount. Packaging machinery that utilizes IoT technologies is enabling manufacturers to monitor production efficiency in real-time, thereby reducing waste and increasing output quality.

Tip: Consider integrating smart technology in your blister packaging line to facilitate predictive maintenance. This can greatly reduce downtime and enhance operational efficiency.

In addition, the trend towards eco-friendly materials is gaining traction, with a 30% increase in demand for sustainable packaging options reported by Packaging Innovations. Manufacturers implementing biodegradable and recyclable materials not only comply with stringent regulations but also cater to a more environmentally conscious consumer base. Moreover, advancements in digital printing technologies are allowing for more personalized packaging solutions, enabling brands to engage customers in innovative ways.

Tip: Stay ahead of the curve by investing in research on sustainable materials and digital capabilities, which can prove essential for meeting consumer demands and regulatory requirements in the future.

Related Posts

-

Addressing Common Challenges in Blister Pack Packaging: Solutions for Effective Product Protection

-

How to Choose the Right Blister Machine for Your Packaging Needs

-

The Ultimate Guide to Choosing Eco-Friendly Pet Blister Packaging for Your Business

-

Discover the Best Practices for Using a Blister Pack Heat Sealer in Your Packaging Process

-

Unlocking the Secrets of Blister Tooling: A Comprehensive Guide to Efficient Packaging Solutions

-

How to Optimize Blister Tray Packaging for Maximum Product Protection and Cost Efficiency